Lexmark C910 Color Printer Service Manual (323 P.)

Field service documentation for the Lexmark C910 with transfer belt maintenance, LED printhead service, fuser procedures, paper path diagnostics, and high voltage power supply repair instructions.

Manual Preview

Sample pages from the Lexmark C910 Color Printer Service Manual (323 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Lexmark C910 Color Printer (5055-01x) — 2001 Original Specification Catalog | C910 Series Section.

- Engineered Power Rating: For normal operation, 120 V ac / 230 V ac is specified as the electrical input requirements Mapping.

- Design Power Draw: The printer generates 28 ppm (color) requires standard print velocity Configuration.

- Documented Thermal Rating: Fuser heat rollers maintain approximately 200°C (392°F) — delivers operational temperature Benchmarks.

- Principal Unit Dimensions: The printer frame measures 632 mm (L) × 508 mm (W) × 438 mm (H) indicates base assembly Range.

- Advanced Bolt Torques: Transfer belt mounting hardware is set to 2.5 N·m (22 lb-in) controls fastening tension Sequences.

- Primary Interference Fit: LED printhead positioning pins requires ±0.05 mm (±0.002 in) supports locating accuracy Baseline.

Professional Workshop Service Manual & Technical Specifications

Factory-Level Diagnostic Manual: Lexmark C910 Color Printer (5055-01x) Service-Dossier

Service-Level: Lexmark C910 Color Printer (5055-01x) // Design-Core: Copier / Electrophotographic Process Logic // Documentation-Type: Technical service procedures and component replacement data.

| Component Category | System Documentation | Reference Coverage |

|---|---|---|

| Document Overview | 323-page technical reference | Complete specifications provided |

| Imaging Components | LED printhead and photodeveloper systems | Documented in Chapter 4 |

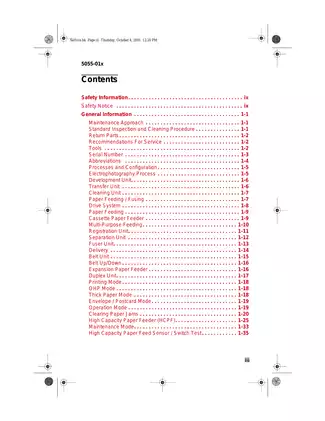

| Paper Handling | Multi-source feeding and duplex capability | See Chapters 1-2 |

| Electrical Systems | Controller boards and power supply units | Complete wiring diagrams included |

| Maintenance Procedures | Preventive service and adjustment protocols | Documented intervals provided |

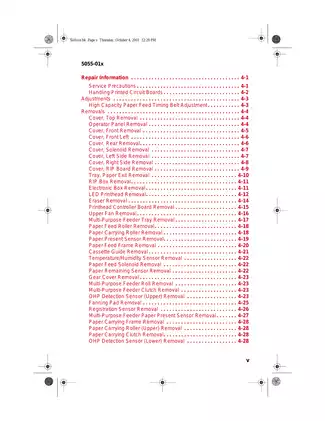

Service procedures are grouped by diagnostic tests, covering removal and replacement sequences, sensor calibration methods, printhead alignment protocols, and hardware validation routines that enable component-level troubleshooting across the imaging subsystem.

The document includes coverage of error code interpretation tables, operator panel diagnostic sequences, transfer belt registration methods, fuser temperature monitoring specifications, and high-capacity paper feeder mechanisms. Verification procedures are included for LED printhead operation, photodeveloper drum tracking, transfer belt positioning accuracy, and paper feed clutch engagement timing. Repair information is provided for power supply circuit boards, motor drive assemblies, sensor board connections, and high voltage control units.

Thorough mechanism documentation addresses the electrophotographic imaging process, multi-layer photoconductor drum construction, development roller toner transfer, charging roller voltage application, and LED exposure array operation. The manual documents torque specifications for the transfer belt mounting hardware to ensure proper vibration dampening. Paper path chapters reference cassette feed mechanisms, multi-purpose tray operation, registration roller synchronization, duplex unit reversal, and face-up/down delivery switching. Color calibration data encompasses density sensor positioning, CMYK printhead alignment values, drum gear detection timing, and toner remaining detection thresholds.

Parts catalog assemblies identify base frame components, upper unit structures, electrical harness routing, paper feed roller sets, fuser unit elements, transfer belt assemblies, expansion feeder modules, and high-capacity input drawer configurations.

FAQ

Customer Reviews

Read what our customers say about this Lexmark Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)