2001–2007 Komatsu WB97R-2 Backhoe Loader Shop Manual

This manual covers the Komatsu WB97R-2 series backhoe loader, detailing service procedures, diagnostic flowcharts, and component breakdowns. Ref: WEBM001000

Manual Preview

Sample pages from the 2001–2007 Komatsu WB97R-2 Backhoe Loader Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Komatsu WB97R-2 Backhoe Loader Shop Manual (2001–2007) Hydraulic-Guide Komatsu WB97R-2 (2001 – 2007) | Komatsu WB97R-2A | Komatsu WB97R-2B. Established Operational Data: 434 Pages defines the manual's comprehensive coverage. Baseline Tightening Data: 78.4–98 Nm signifies the mounting torque for the starting motor. Operational Consumption Data: 21.9239 MB indicates the digital file size for easy access. Specific Electrical Load: 70A is the rating for the fuel shut-off motor fuse. Baseline Power Rating: 80A is the rating for the blower motor fuse. Integral Tightening Data: 35.2 Nm is the torque for pump-locking nuts.

Professional Workshop Service Manual & Technical Specifications

Industrial Installation Calibration Manual: Backhoe Loader Complete Guide: Komatsu WB97R-2 Backhoe Loader Shop Manual (2001–2007) Hydraulic-Guide

Technical-Scope: 434 Pages // Documentation-Type: Shop Manual / Service Manual // Operational-Scope: Complete Guide. Repair procedures are structured around the following key systems and components: System operation descriptions cover the powertrain, transmission, front and rear axles, and steering systems. The documentation addresses hydraulic circuits, pumps, and control valves, providing detailed schematics and operational principles. Assembly instructions are detailed for components like the boom, arm, and bucket cylinders, and outriggers. Hydraulic schematics are included for the entire system, detailing the flow and control mechanisms. Steering component information is provided for the hydraulic steering unit and relevant control valves. The manual documents torque specifications for component reassembly to ensure proper joint sealing.

Component Specifications

The manual contains detailed specifications for various components, including:

- Engine: Standard and permissible values for idle speed, exhaust gas color, valve clearance, and compression pressure.

- Machine: Travel lever and pedal specifications, including accelerator pedal, front bucket tilt, and arm control.

- Hydraulic Systems: Pressure settings for control valves, including 3-spool, 6-spool, 7-spool, and 8-spool configurations, as well as specific settings for the steering control system.

Key Systems Covered

This manual provides comprehensive documentation for the following hydraulic and mechanical systems:

- Powertrain: Details on transmission, convertor, and final drive assemblies.

- Hydraulic System: Includes diagrams and explanations for pumps, cylinders (boom, arm, bucket, outriggers), and control valves.

- Braking System: Covers brake pump testing, group testing, and related procedures.

- Air-Conditioning Unit: Details on compressor removal/installation and system function.

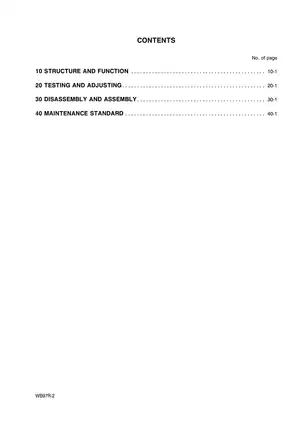

Table of Contents Summary

- Testing and Adjustments: Includes special tools, measuring engine speed, and adjusting valve clearance.

- Removal and Installation: Detailed procedures for removing and installing major components like the starting motor, alternator, and injection pump.

- Hydraulic Circuit Diagrams: Comprehensive schematics illustrating the flow and control of hydraulic systems.

- Troubleshooting: Analysis of causes for hydraulic drift in front equipment, backhoe, and other actuators.

- Electrical Diagrams: Schematics for various electrical systems, including engine control and lighting circuits.

Key Procedures and Information

Sequentially establishing proper maintenance and repair is crucial for optimal performance. This manual provides clear instructions for the removal and installation of key components such as the starting motor, alternator, and injection pump. It also details testing and adjustments for critical systems, including hydraulic circuit pressure checks and engine speed control under load. The content covers analysis of causes for hydraulic drift and provides detailed electrical diagrams for troubleshooting. It covers procedures for removing and installing the radiator-oil cooler unit, turbocharger, cylinder head, and front counterweight to ensure proper machine maintenance.

FAQ

Customer Reviews

Read what our customers say about this Komatsu Backhoe Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)