1975-1980 Case 580C Construction King Loader Backhoe Operation and Maintenance Manual

Technician-level documentation for Case 580C backhoe-loader operation, safety procedures, and maintenance. Covers engine systems, hydraulics, loader bucket, and backhoe dipper operations plus routine service intervals and component troubleshooting.

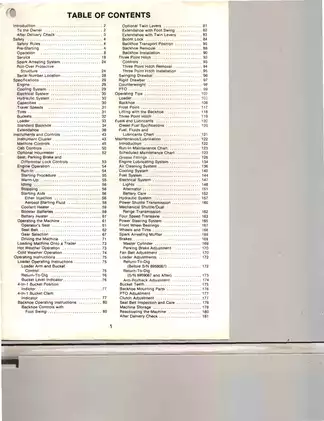

Manual Preview

Sample pages from the 1975-1980 Case 580C Construction King Loader Backhoe Operation and Maintenance Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Case 580C Construction King — 1975–1980 Mechanical Operational Specification Repository | 580C Series Repository.

- System Volume Data: The hydraulic reservoir capacity is calibrated to 57 L (15 gal) for standard operation Requirements.

- Core Spacing Data: For proper bucket clearance, 2438 mm (96 in) maximum reach is designed for digging depth Threshold.

- Specific Wattage Specs: Engine displacement provides 3638 cc (222 cu in) cubic capacity Mapping.

- Critical Cold Start Limits: The starting system requires 12 V electrical supply governs engine ignition Configuration.

- Universal Form Factor: Maximum operating pressure reaches 17237 kPa (2500 psi) establishes hydraulic system Benchmarks.

- Calibrated Liquid Volume: Fuel tank capacity determines 114 L (30 gal) for extended field operation Range.

Professional Workshop Service Manual & Technical Specifications

Technical Wiring Manual: Case 580C Construction King Loader Backhoe Operator's Manual Specification-Set

Engineering-Metrics: Case 580C Construction King (1975-1980) // Coverage-Scope: Diesel engine, hydraulic systems, and power train systems Logic // Year-Coverage: 1975-1980 production models.

| Document Section | Systems Included | Reference Information |

|---|---|---|

| General (Series 10) | Engine specifications and maintenance data | Torque charts and lubrication specifications documented |

| Engine (Series 20) | Diesel engine, cylinder head, crankshaft, cooling | Complete engine diagnostic procedures included |

| Fuel System (Series 30) | Fuel pump, injectors, fuel lines, tank | Fuel system specifications documented |

Cataloging major assemblies into engine specifications, fuel system procedures, hydraulic system diagrams, electrical wiring, and brake system details, the document provides comprehensive technical reference spanning diagnostics, component configuration, and maintenance protocols. The manual presents information on diesel engine operation, encompassing specifications in both U.S. and metric measurements. Reference data is included for lubrication intervals, fluid capacities, and maintenance schedules organized by operating hours. This manual covers hydraulic systems encompassing the loader control valve, backhoe control valve, cylinders, and stabilizer systems. Diagnostic procedures are covered for engine troubleshooting including starting failures, misfiring, overheating, power loss, oil consumption issues, and pressure anomalies.

Wiring diagrams are provided for the electrical system including battery, starter, alternator, and instrument cluster configurations. Fuel system procedures are documented for fuel filters, injection pump settings, and fuel injector maintenance. The document includes torque specifications for fastener reassembly to ensure proper joint integrity and component retention. The 188-page reference contains maintenance procedures organized by service intervals ranging from initial run-in through annual maintenance cycles, specification tables for engine measurements, hydraulic pressure reference points, and system-specific diagnostic flowcharts for identifying and addressing operational issues.

FAQ

Customer Reviews

Read what our customers say about this Case Backhoe Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)