1998-2002 JCB 426 Wheeled Loader Service Manual (117 P.)

Troubleshooting and service procedures for JCB 426, 436, 446 wheeled loaders — transmission, engine, hydraulics, brakes, steering, and electrical systems. PN 9803/4160.

Manual Preview

Sample pages from the 1998-2002 JCB 426 Wheeled Loader Service Manual (117 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

JCB 426 Wheeled Loader (9803/4160) — 1998–2002 Consolidated Engineering Archive | 426 Series Section.

-

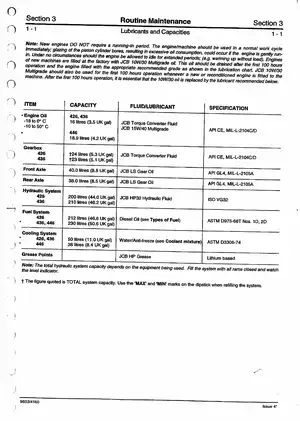

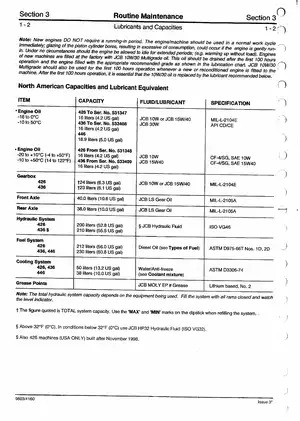

Nominal Engine Oil Volume: 16 liters (3.5 UK gal) is configured at the capacity specification Engine configuration for all standard 426 machines Mapping.

-

Principal Transmission Fluid Capacity: For optimal loader hydraulic operation, 23 liters (5.1 UK gal) produces the gearbox fill volume Framework for 436 series machines Fit Tolerances.

-

Rated Hydraulic System Pressure: 9 bar (130 lbf/in²) — maintains the converter input pressure threshold Voltage Specs at maximum relief setting Benchmarks.

-

Technical Engine Cooling Capacity: The 426 machine requires 50 liters (11.0 UK gal) coolant/water mixture is established at system thermal range Output Performance for 50/50 ELC configuration Baseline.

-

Standard Fuel Tank Volume: 212 liters (46.6 UK gal) is set to the diesel oil supply Net Mass for standard operational Sequences across 426 loader variants.

-

Design Stall Speed Setting: Main pump system pressure reaches 2180 r.p.m. combined transmission/hydraulic measurement requires the full load speed Fluid Levels baseline for WG-160 transmission variant Parameters.

Professional Workshop Service Manual & Technical Specifications

Practical Training Manual: Wheel Loader Detailed JCB 426 Wheeled Loader Service Manual # 9803/4160 – 107 Pages | Factory Grade Blueprint-Vault

Documentation-Type: JCB 426, 436, 446, 426 USA, 436 USA, 426B (YB Build) // Model-Specs: Wheeled Loader Full Coverage / Transmission and Hydraulic Systems Logic // Service-Level: Factory Authorized Technical Reference - Complete System Coverage.

| Metric | System-Path | Calibration-Data |

|---|---|---|

| Engine Oil Capacity | Lubrication Framework | 16 liters (3.5 UK gal) documented |

| Coolant System | Thermal Architecture | 38–50 liters at 50/50 ELC mixture ratio |

| Hydraulic System | Pressure Regulation | 200–212 liters with multiple circuit specifications |

| Transmission Fluid | Power Transfer Circuit | 23–34 liters per configuration model |

| Axle Lubrication | Front/Rear Differentials | 37–40 liters per side assembly |

Outlining the operational framework across engine and transmission systems, the documentation examines routine maintenance procedures, addresses hydraulic control architecture, and explores steering and braking subsystems. The manual encompasses control systems integration, alongside pressure regulation mechanisms, while detailing electrical system configurations and addressing transmission operational parameters. Service scheduling guidelines and diagnostic reference information complete the technical foundation.

Wiring diagrams are provided for all electrical circuits, illuminating the interconnection of engine management systems, transmission controllers, and vehicle safety networks. Fuel system procedures are documented for tank capacity specifications, fuel type requirements, and filtration maintenance across the 1998–2002 production span. Adjustment procedures are detailed for valve clearance reference data, engine idle control settings, and hydraulic pressure calibration across primary and secondary pump assemblies. Timing procedures are documented for transmission shift control, engine speed sensor synchronization, and emergency steering system activation protocols. Technical notes are provided for electrical fault diagnosis, wiring harness routing through multiple chassis zones, and connector identification standards throughout the vehicle architecture.

The manual documents torque specifications for engine mounting studs, cylinder head securing bolts, and transmission coupling assemblies to ensure proper bearing preload accuracy. Hydraulic circuit schematics illustrate the relationship between main pump systems, steering valve assemblies, loader control circuits, and auxiliary hydraulic functions. Electrical schematic diagrams depict the routing of primary and secondary fuse blocks, relay logic for ignition systems, and CAN-bus communication pathways integrating engine monitoring with transmission computer units. Component identification tables cross-reference part numbers with functional descriptions, enabling systematic service procedures across engine, transmission, hydraulics, and cab electrical installations.

Table Role: Document Overview

| Chapter Overview | System Coverage | Reference Data |

|---|---|---|

| General Information & Safety | Machine configuration and hazard warnings | Warning symbols and safe work procedures |

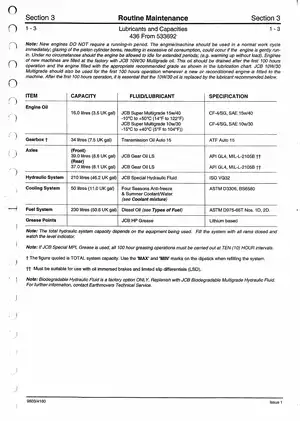

| Routine Maintenance | Service intervals at 10, 100, 250, 500, 1000, and 2000 hour checkpoints | Lubricant specifications, capacity tables, and greasing point locations |

| Transmission & Axles | Powershift transmission operation, oil level procedures, and filter replacement | WG-160/190 technical data, pressure test points, fault code directory |

| Hydraulics | Pump pressure testing, loader valve relief settings, and system schematic circuits | Steering valve pressures, accumulator charging procedures, and component key references |

| Electrics | Wiring harness routing maps, fuse panel locations, and circuit diagram collections | Fault-finding techniques, multimeter usage, and connector pin assignments |

| Brakes & Steering | Brake system bleeding, parking brake adjustment, and emergency steer procedures | Steering pressure specifications and relief valve setting protocols |

FAQ

Customer Reviews

Read what our customers say about this JCB Wheel Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)