1970-1982 JCB 2D / 2DS / 3 / 3C / 3CS / 3D / 700 Workshop Service Manual

Technical reference spanning excavator loader models MK 2 & MK 3. Includes manual transmission and torque converter configurations with complete specifications and service procedures.

Manual Preview

Sample pages from the 1970-1982 JCB 2D / 2DS / 3 / 3C / 3CS / 3D / 700 Workshop Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

JCB 2D, 2DS, 3, 3C, 3CS, 3D & 700 — 1970–1982 Automotive Engineering Documentation | Excavator Series Kit.

- Verified Installation Footprint: Engine displacement of 3.77 litres (230 cu in) is rated at the BLMC 38TD four-cylinder diesel configuration Bounds.

- Key Maximum Resolution: Pump flow at 2000 rev/min and maximum pressure establishes 102 litres/min (22.5 UK gal/min) output topology Matrix.

- Principal Twist Specifications: For hydraulic system operation, main relief valve pressure of 138 bar (141 kgf/cm² 2000 lbf/in²) supports critical component protection Standards.

- Advanced Deviation Limits: The main hydraulic system requires capacity ranges from 173 litres (2D, 3) to 205 litres (3D) depending on machine model configuration Logic.

- Defined Operating Temps: Torque converter oil operates at normal temperatures of 90–100°C with maximum intermittent service capability of 120°C governs thermal margin Protocol.

- General Gross Dimensions: Engine idling speed achieves 700–720 rev/min with maximum governed speed of 2000 rev/min establishing baseline operating performance guidelines Guidelines.

Professional Workshop Service Manual & Technical Specifications

Multi-System Quality Wiring Manual: JCB 2D, 2DS, 3, 3C, 3CS, 3D & 700 MK 2 & MK 3 Excavator Loader - Workshop Service Manual & Repair Guide (1970-1982) Diagnostic-Reference

Serial-Range: JCB 2D, 2DS, 3, 3C, 3CS, 3D, 700 (MK 2 & MK 3 models) // Coverage-Scope: Multi-system excavator and loader equipment service documentation // Machine-Range: Complete workshop resource covering 472 pages of technical content.

| Performance-Element | Parameters | Framework |

|---|---|---|

| Engine Systems | Specifications, torque data, fuel system procedures | Complete engine documentation |

| Hydraulic Architecture | Pump flow rates, relief valve settings, circuit diagrams | Includes system relief and auxiliary relief specifications |

| Transmission Assembly | Gear ratios, clutch specifications, torque converter data | Complete transmission specifications provided |

| Brake and Steering Systems | Adjustment procedures, pressure specifications | Documented system parameters |

| Electrical Components | Battery testing, charging circuit checks, wiring diagrams | Complete electrical system framework |

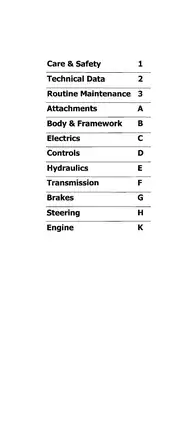

Following OEM groupings, the manual includes comprehensive coverage of engine and fuel system operation, transmission and gearbox configuration, hydraulic system design and component specification, electrical charging and starting systems, brake system maintenance and adjustment, steering system documentation, and body and framework assembly procedures. These topics flow throughout the comprehensive workshop reference covering multiple machine build variations across the MK 2 and MK 3 model ranges.

Structured Benchmarks

Service procedures are documented for component removal, hose and pipe disconnection, dismantling and assembly sequences, bearing inspection and replacement, and pressure testing methodologies. The document references real technical specifications including pump flow rates at operational engine speeds, relief valve operating pressures in multiple measurement units, transmission gear ratios, and hydraulic system capacities across different machine configurations.

Systematic Framework

Calibration requirements are specified for clutch adjustment, brake system alignment, steering geometry (including camber angle, castor angle, and toe-in measurements), and fuel injection timing settings for different engine variants (38TD and 4/98 engines). Electrical system documentation covers battery specific gravity testing procedures, alternator charging circuit checks, starter motor performance testing, and dynamo operation verification with specific voltage and amperage parameters documented.

Strategic Logic-Path

Electrical system documentation covers wiring diagram sequences for multiple market variants, battery maintenance and testing methodologies, alternator and dynamo circuit analysis, and control box adjustment procedures. Troubleshooting logic for starting systems, charging systems, and lighting systems is included with fault diagnosis flowcharts.

Comprehensive Nexus

Suspension service documentation covers front axle adjustment, grease point identification for loader and excavator configurations, pivot pin lubrication schedules, and propshaft maintenance. The manual documents torque specifications for ram piston heads, cylinder end bolts, slew actuator components, and structural fasteners using both metric and imperial measurement standards.

Technical Sequences

Disassembly instructions are documented for double pump systems (Hamworthy and Commercial variants), flow dividers for roadbreaker and hydraulic power take-off attachments, relief valve assemblies, and control valve configurations. The document includes detailed breakdown sequences for boom and dipper removal, kingpost carriage assembly, and slew actuator dismantling with reassembly procedures.

This manual documents torque specifications for critical fasteners to ensure proper cyclic stress resistance, with specifications provided across multiple bolt grades and sizes.

FAQ

Customer Reviews

Read what our customers say about this JCB Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)