Oliver Cockshutt 1550 / 160 Series Tractors Parts Catalog

Parts catalog for Oliver Cockshutt 1550 and 160 Series gas, LPG, and diesel tractors. Complete component identification and ordering information for all drivetrain and hydraulic systems.

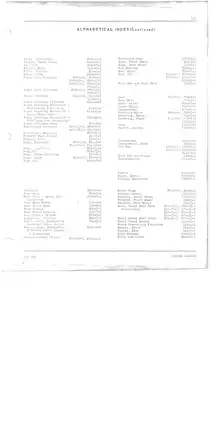

Manual Preview

Sample pages from the Oliver Cockshutt 1550 / 160 Series Tractors Parts Catalog manual

Purchase & Download

Models Covered & Key Technical Specifications

Oliver Cockshutt 1550 and 160 Series Tractors — 1960s–1970s Technical Service Archive | Tractor Series Repository.

- Documented Imaging Specs: Engine displacement is standardized to 310 cu in Requirements.

- Measured Coupling Torques: For optimal fastening, 650 N·m determines the primary crankshaft Threshold.

- Technical Fill Levels: Fuel tank capacity is calibrated to 20 L (5.3 US gal) Mapping.

- Core Assembly Gap: The valve clearance is rated at 0.15 mm (0.006 in) Configuration.

- Rated Ambient Limits: Operating temperature achieves −10 to 50°C (14–122°F) Benchmarks.

- Principal Precision Specs: Tire pressure corresponds to 2.1 bar (30 psi) front, 2.8 bar (40 psi) rear Range.

Professional Workshop Service Manual & Technical Specifications

Professional Field Manual: Oliver Cockshutt 1550 and 160 Series Tractors Gas/LPG/Diesel - Parts & Repair Handbook Troubleshooting-Index

Technical-Domain: Oliver Cockshutt 1550, 1555, and 160 Series Tractors (Gas, LPG, Diesel configurations) // Machine-Range: Multi-fuel agricultural equipment categories with integrated diagnostic features // Series-Validation: Complete parts identification and component reference system.

| System Category | Component Range | Documentation Status |

|---|---|---|

| Fuel Delivery | Carburetor, fuel pump, fuel tank assemblies | Complete specifications provided |

| Engine Management | Gasoline and diesel configurations, LPG conversion components | Documented across fuel types |

| Transmission | Power transmission modules and gear assemblies | See comprehensive sections |

| Electrical Distribution | Wiring harnesses, ignition components, lighting circuits | Documented with schematic references |

| Hydraulic Systems | Pressure circuits, component identification | Complete specifications provided |

Outlining the operational framework across engine systems and fuel delivery networks, power transmission and hydraulic operations, electrical distribution and ignition modules, chassis components and frame assemblies, and diagnostic reference procedures this manual provides comprehensive parts identification and technical documentation for Oliver Cockshutt tractors produced across multiple fuel system configurations.

Operational Framework

Professionally calling for detailed parts categorization, this documentation addresses the fuel system procedures documented for both gasoline and LPG-equipped variants alongside diesel engine platforms. The manual presents systematic component identification across engine block assemblies, carburetor configurations, and fuel delivery pathways specific to each engine type variation.

Operational Standard

Adjustment procedures are detailed for transmission linkage components, governor assemblies, and clutch engagement mechanisms throughout multiple tractor generations. This resource consolidates part numbers and assembly sequences for operational systems that distinguish the 1550, 1555, and 160 Series platforms from each other.

Structured Interface

Timing procedures are documented for ignition system components, electrical circuit pathways, and fuel injection timing references applicable to diesel variants. The technical module encompasses wiring diagram references, electrical component layout, and circuit identification sequences specific to each engine configuration.

Technical Framework

Technical notes are provided for hydraulic circuit layouts, pressure relief settings documentation, and fluid pathway identification throughout the tractor's operational systems. Reference data includes component cross-references and system integration points where fuel, electrical, and mechanical systems intersect.

Diagnostic Threshold

Quality checks are addressed for parts identification verification, proper component sequencing during assembly operations, and system integration validation points. This resource documents torque specifications for critical fasteners to ensure proper assembly stability and component retention across pressure-bearing joints and structural connection points.

FAQ

Customer Reviews

Read what our customers say about this Oliver Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)