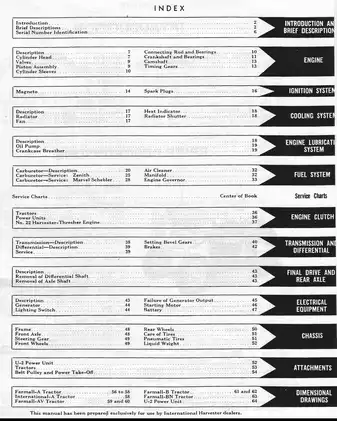

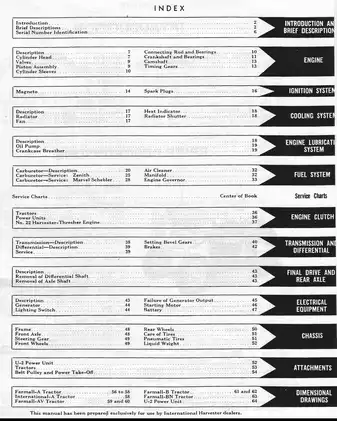

1939-1952 Farmall A/B/AV/BN International A U-2 Service Manual (64 P.)

Complete 4-cylinder engine, transmission, and electrical service specifications — ignition timing, carburetor adjustment, fuel system, cooling, lubrication, and drive train procedures. Publication form CHS-27.

Manual Preview

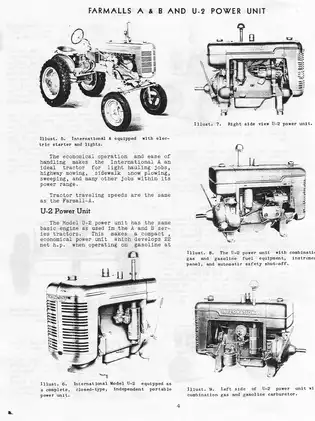

Sample pages from the 1939-1952 Farmall A/B/AV/BN International A U-2 Service Manual (64 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Farmall A, B, AV, BN Tractors & International A Industrial Tractor — 1939–1947 Applied Reference Package | Farmall-International Series Repository.

- Reference Coupling Torques: 65 ft. lb. is calibrated to the cylinder head stud nut tension Sequences.

- Integral Twist Specifications: For proper engine operation, 4-cylinder displacement of 113 cubic inches governs the piston assembly Architecture.

- General Holding Capacity: 3-3/8 gallons — is specified as the cooling system capacity Baseline.

- Essential Load Capacity: The transmission case requires 1-1/2 gallons for splash lubrication Requirements.

- Baseline Cycle Rate: Relief valve setting provides 50–60 lb. at 1400 rpm Threshold.

- Fundamental Torque Data: Maximum engine speed is rated at 1400 rpm for tractors Configuration.

Professional Workshop Service Manual & Technical Specifications

Factory-Level Diagnostic Manual: Tractor Official Farmall A, B, AV, BN Tractors & U-2 Power Unit - 1939-1952 Coverage & Repair Procedures Service-Catalog

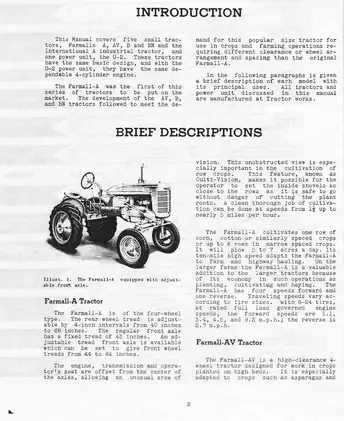

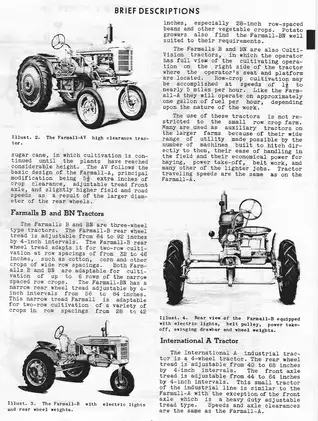

Specification-Class: Farmall-A, Farmall-AV, Farmall-B, Farmall-BN, International A industrial tractor, Model U-2 Power Unit, No. 22 Harvester-Thresher Engine // Design-Core: 4-cylinder engine systems, transmission and differential architecture, cooling and fuel system logic // Unit-Designations: 64-page technical reference documenting mechanical assemblies and operational specifications from 1939-1952 manufacturing period.

| Document Overview | Coverage Area | Technical Content Included |

|---|---|---|

| Engine Systems | Cylinders, pistons, crankshaft, camshaft, bearings | Sectional views, material specifications, clearance data documented |

| Fuel & Ignition | Carburetor types (Zenith, Marvel Schebler), magneto, spark systems | Multiple carburetor variants, jet specifications, timing reference data |

| Transmission & Differential | Four-speed selective spur gear, bevel drive assemblies | Gear ratios, bearing configurations, adjustment procedures documented |

Engineering chapters address the cylinder head design methodology, exploring valve timing specifications and corrosion-resistant materials through documented casting procedures. The manual continues by examining crankshaft bearing arrangements, then progresses to connecting rod assemblies with their tolerance data and lubrication pathways. Fuel carburetor systems receive corresponding attention, with detailed breakdowns of float mechanisms, idle jets, and load compensation methods across both gasoline and distillate-burning variants. The transmission section references gear reduction ratios and bevel gear alignment principles for field adjustments.

Fluid capacities are listed for the transmission case (1-1/2 gallons), engine crankcase (2.5 quarts), and rear axle housings (3 pints per side), establishing proper fill specifications before operation. Installation guidelines are provided for removable cylinder sleeves, precision-type connecting rod bearings, and magnetic ignition components to ensure correct assembly sequences. Maintenance guidelines are included for carburetor service on both Zenith Model 161 and Marvel Schebler TSX units, with systematic disassembly charts identifying main jet sizes, venturi dimensions, and idle passage configurations. OEM guidelines are included for electrical equipment servicing, including generator cutout relay operation, starting motor brush inspection, and battery electrolyte level maintenance protocols.

The document references torque specifications for cylinder head studs, main bearing cap bolts, and flywheel attachment fasteners to ensure proper assembly tension. Comprehensive wiring diagrams illustrate the correct pathway for magneto spark timing, generator field circuit management, and starter motor control circuits. Dimensional drawings for each model variant capture wheel base measurements, drawbar configuration options, and tire rolling radius data across multiple rim and tire size combinations. The manual provides specifications data for the standardized power take-off shaft system (1-3/8" spline diameter), belt pulley rotation speed (1956 r.p.m. at governed load), and optional pulley diameter options ranging from 6-3/4 inches to 10-3/4 inches.

Traveling speed charts document first through fourth gear ratios under rated load conditions, accounting for tire size variations (8-24, 9-24, 8-36, and 9-36 inches) and their corresponding rolling radius measurements. The manual includes specifications for two front axle designs: the lighter tubular construction on Farmall-A models and the heavy-duty adjustable type on Industrial A, along with rear axle housing configurations unique to B and BN variants. Brake system data encompasses band width dimensions (1-3/4 inches by 18 inches), drum braking area (31-1/2 square inches per drum), and clevis adjustment methodology for achieving correct pedal free movement. Detailed assembly diagrams show the interconnection of differential shaft housing configurations, with separate castings on Farmall-B and BN models versus the integrated design of Farmall-A. Cooling system specifications include thermosiphon circulation principles, fan diameter and blade configuration, and radiator shutter operation on kerosene-burning engine variants.

The manual documents torque specifications for multiple fastener categories to ensure proper assembly and cyclic stress resistance. Charts reference governfour governor weight types, spring identification numbers, and spring tension test values under load. Tables list jet identification data for both Zenith and Marvel Schebler carburetors, cross-referencing part numbers with engine variants and fuel types. Serial number identification sections correlate machine chassis numbers with engine serial assignments for accurate parts lookup and service record tracking across all model variants from 1939-1947 production years.

FAQ

Customer Reviews

Read what our customers say about this Farmall Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)