EURO-PRO 464XC, 464, 412N Sewing Machine Service Manual

Service manual for the EURO-PRO 464XC, 464, 412N sewing machines. Includes diagnostics, repair procedures, and maintenance guidelines. Publication rev_0407a_rw.

Manual Preview

Sample pages from the EURO-PRO 464XC, 464, 412N Sewing Machine Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Detailed Training Technical Manual: Sewing Machine Official Euro -PRO 464XC, 464, 412N Sewing Machine Service & Maintenance Manual - Diagnostics & Repair Procedures Assembly-Guide EURO-PRO 464XC, 464, 412N (rev_0407a_rw) - Sewing Machine Record. // Official Euro -PRO / Sewing Machine Logic // Technical-Domain: Machine Assembly Logic.

- Approved Circuit Specs: For proper functioning, 120 V corresponds to the standard operating voltage Standards.

- Factory Heat Tolerance: The control panel sets operational limits for 15-30°C Margin.

- Primary Processing Speed: The motor achieves speeds of up to 1500 rpm Protocol.

- General Resolution Data: The needle plate requires a thickness of 1.0 mm for optimal sewing Architecture.

- Essential Twist Specifications: For stable stitching, 16 N sets the necessary thread tension Norms.

- Operational Power Framework: The sewing light yields 60 W for adequate illumination Matrix.

Professional Workshop Service Manual & Technical Specifications

Detailed Training Technical Manual: Sewing Machine Official Euro -PRO 464XC, 464, 412N Sewing Machine Service & Maintenance Manual - Diagnostics & Repair Procedures Assembly-Guide

Technical-Domain: EURO-PRO 464XC, 464, 412N // Engine-Type: Sewing Machine / Electric Logic // Technical-Domain: Machine Assembly Logic.

| Service-Nexus | System-Path | Calibration-Standards |

|---|---|---|

| Operation | Threading | Upper Thread Tension |

| Maintenance | Lubrication | Oil Application |

| Troubleshooting | Needle | Needle Alignment |

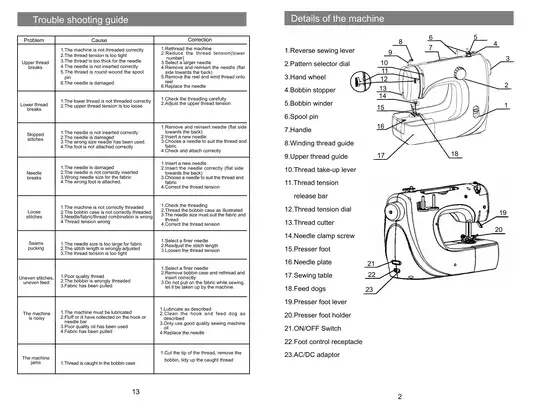

| Accessories | Attachments | Presser Foot |

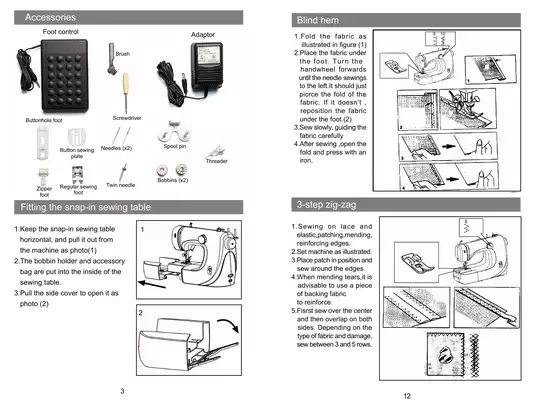

| Stitching | Patterns | Zigzag Settings |

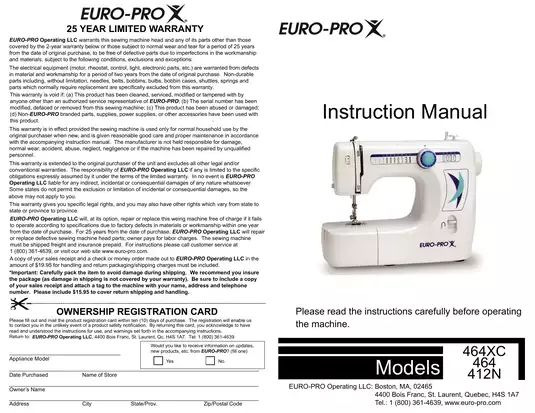

Major sections focus on Troubleshooting guide and details of the machine, providing insights into common problems and their solutions. It covers issues like upper thread breaks, lower thread breaks, skipped stitches, and seam puckering, offering specific correction steps.

Reassembly procedures are specified for

This manual details reassembly procedures for various components after maintenance or repair. It guides users through correctly putting the machine back together to ensure proper function and longevity.

Service intervals are documented for

Service intervals are documented for routine maintenance tasks, including lubrication and cleaning of specific parts like the hook and needle bar, to keep the sewing machine in optimal working condition.

Component locations are identified for

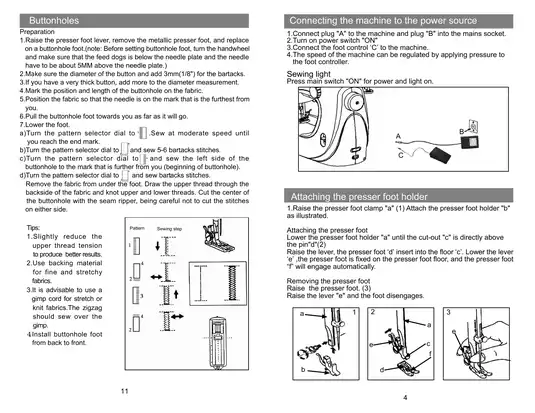

Component locations are identified for key parts such as the spool pin, needle clamp screw, and presser foot, helping users to quickly locate and access the necessary components for adjustments or replacements.

Service procedures are documented for

Service procedures are documented for tasks like threading the upper and lower threads, inserting the needle, and attaching the presser foot holder, ensuring that users can perform these operations correctly and safely.

Calibration requirements are specified for

Calibration requirements are specified for ensuring accurate stitch length and thread tension. The manual explains how to adjust the thread tension dial and stitch length settings for optimal results.

The manual also documents torque specifications for attaching the presser foot holder to ensure proper mating surface contact.

FAQ

Customer Reviews

Read what our customers say about this Euro Sewing Machine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)