New Holland L225 / L325 / L425 / L445 Repair Manual (120 P.)

Hydraulic system overhaul specifications for transmission pumps and motors — lift control valve adjustments, final drive chain service, electrical system troubleshooting. Complete torque data and parts reference.

Manual Preview

Sample pages from the New Holland L225 / L325 / L425 / L445 Repair Manual (120 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

New Holland L225, L325, L425, L445 — 1985–1990 Comprehensive Structured Compendium | Skid Steer Series Kit.

- Design Weight Data: Operating weight reaches 3,028 lb. (1,373 kg) for the L-225 loader configuration Specifications.

- Calibrated Net Mass: For the L-425 configuration, 3,188 lbs. (1,446 kg) is standardized to full fuel tank capacity Protocol.

- Measured Output Density: The main hydraulic pump achieves 7.3–8.1 GPM (27.6–30.6 l/min) — specifies the lift system flow rate Standards.

- Standard Capacity Limits: The L-445 chain case reservoir requires 16 gal. (57 l) for hydraulic operation Architecture.

- Principal Energy Draw: Horsepower ratings range from 18 @ 3,000 RPM (L-225) to 30 @ 2,800 RPM (L-425/L-445) dictates the engine output Matrix.

- Key Angular Speed: Fast engine speed is calibrated to 2,450–3,200 RPM depending on model, representing the governed maximum throttle Norms.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Reference Manual: Skid Steer Loader New Holland Skid Steer Loader Operation & Repair Manual for: L225, L325, L425, L445 Repair-Index

Operational-Scope: L-225, L-325, L-425, L-445 // Reference-Category: Hydrostatic Systems / Transmission Architecture // Component-Focus: Pump and Motor Assembly Details.

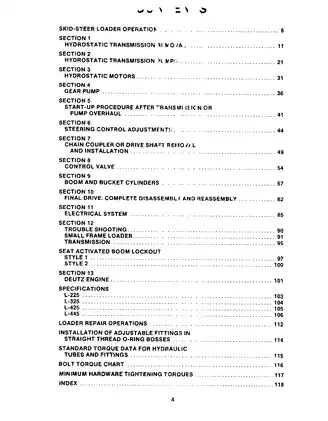

Technical units are distributed across hydrostatic transmission systems, steering mechanisms, boom and bucket control architecture, final drive assemblies, and electrical circuit documentation. The manual contains comprehensive coverage of engine specifications for Wisconsin gasoline, Kohler gasoline, and Deutz diesel configurations, extending through electrical system diagnostics for alternator testing and charge pressure monitoring. Inspection guidelines are provided for variable displacement piston pumps, fixed displacement piston motors, gear pump assemblies, and pilot-operated relief valve systems. Alignment specifications are included for transmission control linkage, steering damper neutralizer positioning, and final drive chain slack measurement procedures. Reference data is included for charge pressure settings, relief valve pressure thresholds, and torque specifications for critical fastening points throughout the loader frame and hydraulic circuits. This manual covers the complete disassembly and reassembly methodologies for hydrostatic motor rotating piston block assemblies with bronze shoe and carburized thrust race components, along with detailed parts identification for charge check valves, cam plate assemblies, and piston block rotating assemblies.

| Component | Value | Validation-Data |

|---|---|---|

| Charge Pressure Setting | 90-150 psi | Documented for all models |

| Main System Relief Valve | 2,250 psi | Complete specifications provided |

| Transmission Relief Pressure | 4,000-4,500 psi | See Specifications section |

| Hydrostatic Motor Mounting | 82 ft. lbs. | Cap screw torque requirements |

| Chain Case Drain Configuration | Fixed displacement motors | Documented in hydraulic circuits |

Service sections detail the forward and reverse relief valve configurations used on transmission piston pumps, the case drain line architecture for moving leakage oil from piston pump cases to the reservoir, and the pressure-beyond (PB) fitting arrangement for auxiliary hydraulic system connections. The document includes wiring diagrams for all four loader models (L-225, L-325, L-425, L-445), along with complete electrical system schematics showing alternator output terminals, isolation diode testing configurations, and regulator field circuit continuity procedures. Troubleshooting guidance addresses small frame loader issues, transmission-related problems, seat-activated boom lockout variations (Style 1 and Style 2), and complete transmission efficiency testing methodologies using portable hydraulic circuit testers. The manual documents torque specifications for the hydrostatic motor cap screws to ensure proper fastener load consistency.

Installation procedures are provided for adjustable fittings in straight thread O-ring bosses, standard torque data for hydraulic tubes and fittings with 37-degree flared connections, and bolt torque charts covering final drive service, gear pump cases, transmission assemblies, cylinders, and engine mounting hardware. Engine specifications include ignition timing advance values, valve clearance tolerances, spark plug gap measurements, and breaker point gap positioning for Wisconsin and Kohler gasoline engines, alongside Deutz diesel engine valve clearance data and fuel system details. The document references the operator's manual for additional service and troubleshooting information, contains precautionary statements (Caution, Warning, Danger, Attention, and Important notices) throughout, and provides repair operation time estimates for major assemblies including hydrostatic pump and motor service, final drive component replacement, and engine removal procedures.

FAQ

Customer Reviews

Read what our customers say about this New Holland Skid Steer Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)