1978 Bolens Medium Tube Frame Tractors Service Manual (100 Pages)

Medium Tube Frame tractor service documentation with engine specs, transmission assemblies, electrical systems, fuel and hydraulic components. Form #552875-1

Manual Preview

Sample pages from the 1978 Bolens Medium Tube Frame Tractors Service Manual (100 Pages) manual

Purchase & Download

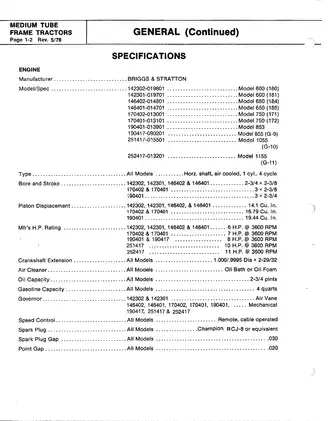

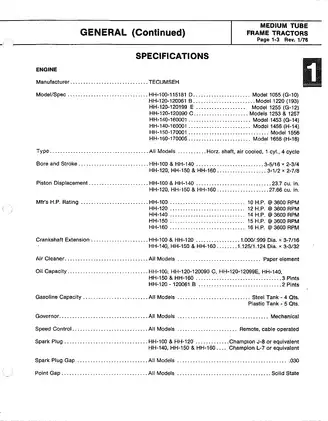

Models Covered & Key Technical Specifications

Bolens 600-1656 Medium Tube Frame Tractors — 1978 Mechanical Industrial Portfolio | Medium Tube Frame Collection.

- Authorized Reservoir Specs: 2-3/4 pints is calibrated to the engine crankcase volume capacity Requirements.

- Published Displacement Data: For engine sizing, 23.7 cu. in. governs the piston displacement on HH-100 and HH-140 Tecumseh engines Threshold.

- Reference Dimensional Tolerance: 3-5/16 x 2-3/4 inches is specified as the bore and stroke measurements on Tecumseh HH-100 and HH-140 models Mapping.

- Fundamental Climate Parameters: For optimal ignition, 0.030 inches supports the spark plug gap specification Configuration.

- Specific Physical Specs: Ground clearance reaches 7 inches at the rear axle on all medium tube frame tractors Benchmarks.

- Core Fluid Capacity: Tank volume is rated at 4 quarts for gasoline storage across all transmission models Range.

Professional Workshop Service Manual & Technical Specifications

Complete Operations Electrical Manual: Bolens Medium Tube Frame Tractors Service & Repair Guide

Technical-Benchmarks: Models 600, 650, 750, 800, 850, 900, 1000, 1050, 1155, 1220, 1253, 1254, 1256, 1257, 1453, 1456, 1556, 1656 // Calibration-Scope: Electrical, ignition, and drivetrain systems documentation // Technical-Benchmarks: Comprehensive specifications across magneto, battery, and solid-state ignition configurations.

| Identifier | Rating | Calibration-Standards |

|---|---|---|

| Magneto Ignition Systems | 6–16 HP models | Documented across multiple configurations |

| Battery Ignition Circuits | Models 850, 1050, 1053, 1054 | Complete wiring specifications provided |

| Solid State Ignition Networks | Models 1220, 1225, 1253–1257, 1556, G14, H14, H16 | Full electrical integration details |

Rigorously requiring technical documentation across powertrain assemblies, the service manual covers wiring diagrams for magneto ignition configurations, battery-operated ignition systems, and advanced solid-state ignition networks spanning the complete model range. The document encompasses transmission systems including 3-speed and 6-speed gear assemblies, hydrostatic transmission packages, and related component configurations with detailed electrical integration for all variants.

The document includes coverage of steering assemblies, brake systems incorporating shoes and disc configurations, clutch mechanisms for both 3-speed and 6-speed platforms, and comprehensive hydraulic power lift systems. Fuel system documentation addresses carburetor adjustments, fuel tank operation, air cleaner service protocols, and fuel filter maintenance across engine manufacturers including Briggs & Stratton, Tecumseh, and Wisconsin Motors. Detailed network specifications provide clear guidance on component relationships and system integration throughout the chassis architecture.

Repair information is provided for drive train components encompassing worm shafts, bearing installations, oil seal applications, and transmission assembly procedures with referenced tool requirements. The document includes a structured troubleshooting guide addressing electrical system failures, drivetrain operation issues, fuel system malfunctions, and engine performance anomalies with systematic remedy procedures. Reference tables document bearing cup dimensions, needle bearing applications, and oil seal component listings for accurate part identification across all model configurations.

Brake system specifications are included for adjustment procedures on transmission shafts, main brake drums, and disc brake assemblies on hydrostatic models. Safety procedures are documented for interlock switch operation including brake, P.T.O., and seat safety mechanisms with adjustment parameters. Hydraulic system documentation covers the principle of operation for optional lift kits, control valve assembly procedures, and charge pump configurations for both earlier and later hydrostatic transmission variants.

Fluid capacities are listed for engine crankcase oils across seasonal temperature ranges, transmission gear lubricants, and hydrostatic fluid specifications with reference to automatic transmission fluid requirements. The document documents torque specifications for transmission fasteners to ensure proper mechanical assembly integrity.

Engine removal procedures are referenced alongside component disconnection sequences and reassembly protocols. The manual provides installation instructions for clutch facing kits and friction disc assemblies with adhesive curing procedures and assembly securing methods using oven-based heat treatment protocols for reliable component adhesion.

FAQ

Customer Reviews

Read what our customers say about this Bolens Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)