2006 Keeway ARN125 / ARN150 Service Manual (84 P.)

Complete service documentation for ARN125/150 scooters addressing engine torque specs, transmission assembly, valve clearance adjustment, carburetor setup, and electrical system diagnostics with troubleshooting procedures.

Manual Preview

Sample pages from the 2006 Keeway ARN125 / ARN150 Service Manual (84 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Keeway ARN125, ARN150 — 2006 Mechanical Industrial Repository | ARN Series Segment.

- Calibrated Climate Specs: 13±1 kg/cm² is standardized to the combustion chamber compression pressure Threshold.

- Prescribed Heat Dissipation: For optimal cooling performance, 100±2 ml defines the front absorber fluid capacity Requirements.

- System Linear Velocity: Throttle engagement achieves 0.6~0.7 mm spark plug electrode gap Mapping.

- Documented Scan Resolution: The carburetor throat tube requires 24 mm diameter for atomization Configuration.

- Defined Liquid Volume: Fuel float chamber reaches 13±1 mm height setting Benchmarks.

- Nominal Generation Capacity: Battery storage sets 7.0 Ah nominal rating for electrical system Range.

Professional Workshop Service Manual & Technical Specifications

Multi-System Instructional Manual: Scooter Keeway ARN125, ARN150 Scooter 2006 - Comprehensive Service & Repair Guide Repair-Index

System-Identifier: ARN125 (2006), ARN150 (2006) // Reference-Category: Technical documentation for engine and transmission system logic // Architecture-Focus: Complete service procedures and component specifications.

| Assessment-Parameter | Diagnostic-Logic | Documentation Status |

|---|---|---|

| Engine systems | Four-stroke operation and component assembly | Complete specifications provided |

| Transmission and clutch | Power transfer and gear shifting mechanisms | Chapter references with assembly sequence |

| Fuel and ignition | Carburetor operation and electronic systems | Functional diagrams and test procedures included |

| Brake and suspension | Hydraulic and mechanical brake systems | System principles and maintenance intervals documented |

| Electrical components | Magneto, battery, and starting systems | Specifications and testing protocols detailed |

Following OEM groupings, the manual includes chapters addressing engine removal and installation, transmission case assembly and component positioning, electrical system testing and CDI diagnostics, brake system principles and maintenance procedures, and periodic service intervals through 12,000 kilometers.

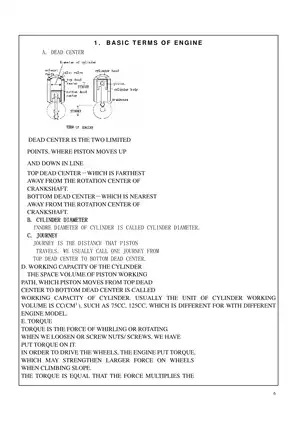

Appropriately establishing a foundation in technical fundamentals, the document provides engine terminology, four-stroke work cycles, and workshop safety protocols. The repository is divided into sections covering engine and transmission specifications with detailed torque documentation for securing fasteners throughout the drivetrain. Technical notes are provided for special service tools required for bearing installation, oil seal positioning, and crankcase assembly procedures. Quality checks are addressed for cylinder pressure measurement, valve clearance verification, and ignition timing inspection across idle and high-speed operating conditions. The fuel system section documents carburetor operation principles including inlet, condensing, idle, slow-speed, and high-speed fuel supply circuits, alongside removal and installation procedures with adjustment steps for mixture ratio optimization.

The troubleshooting chapter addresses engine starting failures, power delivery concerns, unusual noise conditions, electrical system faults, and brake performance issues through systematic diagnostic sequences. Cooling system maintenance is addressed in sections covering lubrication system pathways, oil pump operation, and component circulation routes for crankshaft, camshaft, and transmission element lubrication. The document includes wiring diagrams for charging circuits, signal systems, and electronic ignition components with color-coded lead identification and resistance specifications. Torque specifications are documented throughout for engine assembly, transmission case fastening, frame mounting, and brake system components to ensure proper clamp load consistency.

The manual documents periodic maintenance requirements at 1,000-kilometer intervals for fuel filtration, carburetor adjustment, and spark plug inspection, progressing through 4,000-kilometer service points for oil changes and air cleaner maintenance, with comprehensive 8,000 and 12,000-kilometer checkpoints addressing brake pad wear, suspension fluid levels, and electrical system reliability. Front and rear suspension system assembly procedures include shock absorber structure overview, compression and recovery stroke operation, and oil capacity specifications for dampening performance. Disc brake system principles explain hydraulic pressure transmission through master cylinders and calipers, with detailed disassembly sequences for component inspection and air purging procedures.

FAQ

Customer Reviews

Read what our customers say about this Keeway Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)