2003 Harley-Davidson Dyna / FXD / FXDL / FXDX / FXDXT / FXDWG Service Manual

Factory service manual covering 2003 Dyna models including maintenance procedures, chassis repair, engine service, and electrical diagnostics. Part No. 99481-03A. Complete technical documentation for FXD, FXDL, FXDX, FXDXT, and FXDWG models.

Manual Preview

Sample pages from the 2003 Harley-Davidson Dyna / FXD / FXDL / FXDX / FXDXT / FXDWG Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Harley-Davidson Dyna Super Glide, Low Rider, Wide Glide — 2003 Comprehensive Technical Service Manual | Dyna Series Maintenance Kit.

- Calibrated Engine Oil Capacity: 2.5 quarts (2.4 liters) is designed for wet capacity refill of the Twin Cam 88 V-Twin Engine Specification.

- Rated Primary Chaincase Lubricant: For proper clutch operation, 26 oz (768.9 ml) is configured at the recommended fill level Standard Capacity.

- Published Front Fork Oil Amounts: The FXDWG model requires 12.0 oz (0.36 liters) while FXD/FXDL models require 10.6 oz (0.31 liters) — establishes the sealed fork tube oil capacity Framework.

- Authorized Transmission Lubricant: The transmission requires 20-24 oz (591.5-709.8 ml) of Harley-Davidson approved fluid to achieve proper gear lubrication Protocol.

- Maximum Motorcycle Dry Weight: All standard Dyna models reach 612-642 lbs (277.6-291.2 kg) as the factory-rated curb mass Parameters.

- Documented Tire Pressure Specification: Front wheel maintains 30 psi (207 kPa) solo or two-up, rear wheel requires 36 psi (248 kPa) solo or 40 psi (276 kPa) with passenger for safe rolling Bounds.

Professional Workshop Service Manual & Technical Specifications

Essential Configuration Manual: Harley-Davidson Dyna Super Glide, Low Rider & Wide Glide Service Manual (2003) Data-Compendium

Diagnostic-Area: FXD Dyna Super Glide (2003), FXDX Dyna Super Glide Sport (2003), FXDXT Dyna Super Glide T-Sport (2003), FXDL Dyna Low Rider (2003), FXDWG Dyna Wide Glide (2003) // Assembly-Group: Chassis-Brake-Electrical / Engine-Transmission Logic // Operational-Framework: Complete 525-page reference documentation with diagnostic procedures.

| Metric | System-Path | Context |

|---|---|---|

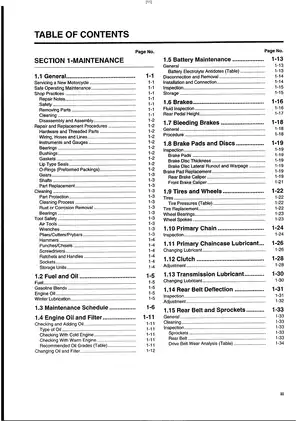

| Maintenance Coverage | Section 1: 29 topic areas | Includes fluid level checks, filter service intervals, brake system inspection |

| Chassis Subsystem | Section 2: Wheels, suspension, fork assemblies | Complete wheel bearing specifications and brake assembly procedures documented |

| Engine Data | Section 3: Top end, bottom end, lubrication | Oil flow pathways, pressure specifications, compression test procedures included |

Maintenance information covers engine oil and filter service, transmission lubricant replacement, primary chaincase lubrication, and brake fluid levels. Battery maintenance procedures, spark plug inspection protocols, air cleaner filter replacement, and fuel system valve screen service are documented with corresponding intervals and specifications. The manual progresses through suspension adjustments for all model variants, steering head bearing adjustment methodology, front fork oil replacement schedules, and tire pressure reference data alongside wheel bearing inspection techniques.

Diagnostic Logic-Path

Repair information is provided for electrical system troubleshooting including alternator charging circuit assessment, speedometer sensor diagnostics, and ignition system verification procedures. The document includes coverage of fuel system overflow conditions, poor idling analysis, acceleration performance issues, and hard starting scenarios with corresponding diagnostic tables. Verification procedures are included for carburetor adjustment operations, enrichener control function, idle speed inspection methodology, and ignition timing reference data.

Structured Threshold

The manual encompasses brake system specifications including master cylinder bore sizes, caliper piston removal procedures, bleeder valve torque specifications, and brake pad replacement sequences across front and rear applications. Documentation addresses front fork oil specifications for all model variants (FXDX cartridge valve design, FXDWG preload adjustment, FXD standard configuration) with corresponding oil quantities and installation tools. Brake disc thickness limits, lateral runout tolerances, and pad material wear thresholds are documented for proper inspection methodology.

Strategic Protocol

Verification procedures are included for wheel trueing, spoke tension measurement, and laced wheel assembly instructions across 16-inch, 19-inch, and 21-inch rim configurations. The document provides belt deflection measurement procedures using specialized tension gauge equipment, rear belt and sprocket wear analysis patterns, and drive belt replacement planning guidance. Vehicle alignment inspection methodology includes rear wheel centerline measurement, stabilizer link adjustment procedures, and brake disc parallelism verification across all model variants.

Modular Architecture

Safety procedures are documented for battery disconnection sequencing, brake system bleeding with fluid pressure maintenance, electrical connector terminal removal/installation using specialized tools, and protective wear requirements during service operations. The manual documents torque specifications for critical fasteners including engine mount isolator bolts, primary chain adjustment hardware, clutch control assembly connections, and rear shock absorber attachment points. Specialized tools are referenced throughout including wheel bearing removal/installation equipment (HD-44060), fork seal bushing installation tools (HD-36583), and steering head bearing race removal systems (HD-39301-A).

Strategic Standard

The document includes wiring diagram indexing for electrical connector locations, Amp Multilock and Deutsch electrical connector specifications, sealed butt splice connector procedures, and connector terminal crimping instructions. Appendix sections provide metric conversion tables, fastener torque value cross-references, and fluid capacity conversion data spanning US standard, metric, and British imperial systems. Engine specifications document compression test procedures, cylinder leakage testing methodology, and smoking engine diagnostic sequences for identifying worn piston rings, valve guide deterioration, and valve seal failure conditions.

Brake system procedures document torque specifications for the critical fastener sets ensuring proper rotational loosening prevention. The manual provides detailed reference information for identification number location, bearing adjustment fall-away measurement techniques, and suspension component preload setting protocols calibrated to rider weight ranges. Documentation covers transmission lubricant dipstick level verification, primary chain slack adjustment methodology, and clutch cable freeplay measurement standards across hand lever assembly configurations.

FAQ

Customer Reviews

Read what our customers say about this Harley-Davidson Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)