1991 Canon NP-4050 Service Manual (326 P.)

Electrophotographic copying process, corona assemblies, drum cleaning, toner supply system. Diagnostic procedures for image formation, pick-up/feeder, fixing and delivery mechanisms.

Manual Preview

Sample pages from the 1991 Canon NP-4050 Service Manual (326 P.) manual

Purchase & Download

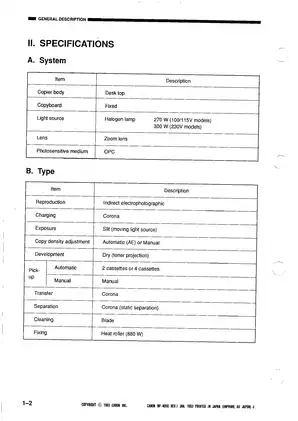

Models Covered & Key Technical Specifications

Canon NP-4050 — 1991–1993 Certified Documentary Specification Repository.

- Reference End Play: 270 W (100/115V) and 300 W (230V) — is calibrated to the scanning lamp power output Architecture.

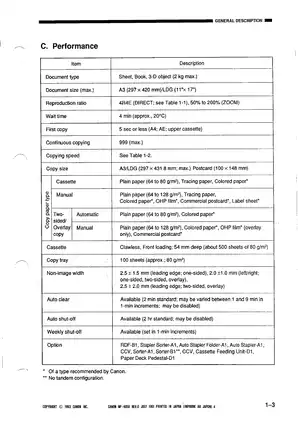

- Approved Power Framework: For optimal operation, 40 copies per minute at A4 100% ratio governs the maximum daily throughput Benchmarks.

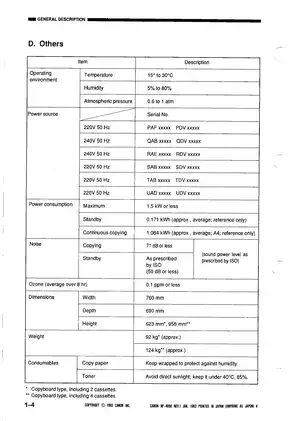

- Designated Ambient Limits: Operating temperature spanning 15–30°C and humidity 5–80% provides the environmental control envelope Specifications.

- Essential Dimensional Limits: The machine requires 760 mm (width) × 690 mm (depth) × 623–958 mm (height) for dimensional accommodation Parameters.

- Baseline Torque Data: Fixing heater rated at 880 W establishes the thermal fusing requirement Configuration.

- Fundamental Measurement Bounds: Maximum power draw measured at 1.5 kW or less determines the electrical circuit capacity Baseline.

Professional Workshop Service Manual & Technical Specifications

Operational Hydraulic Manual: Canon NP-4050 (1991) Service Technical-Repository

Documentation-Type: Canon NP-4050 (1991) // Diagnostic-Area: Copier Service Logic // Machine-Range: Comprehensive Technical Reference.

| Specification | System Coverage | Documentation |

|---|---|---|

| Electrostatic Image Formation | Primary Corona, Transfer, Separation Processes | Complete specifications provided |

| Paper Path Control | Pick-up/Feeder Assembly, Registration Rollers | See Chapters 3–5 |

| Electrical Circuitry | DC Controller, Microprocessor Control | Detailed schematics included |

Integrated service sections encompass general operation and maintenance, copying process sequences, operational timing of all major assemblies, and support for optional paper deck pedestal systems. The documentation references primary corona assembly configuration, transfer and separation corona current control mechanisms, and blank exposure lamp LED management during standard and specialty copy modes.

System operation descriptions cover the photosensitive drum construction, development bias control in both AC and DC components, fixing assembly temperature maintenance at 190°C during copying operation, and cleaning mechanisms for primary and transfer/separation corona wires. The documentation addresses electromagnet-driven pick-up rollers, cassette lifter motors, horizontal registration motor functionality, and scanner drive system operation across fixed and variable reproduction ratios between 50% and 200%.

Assembly instructions are detailed for jam removal from multiple paper path locations, manual toner supply procedures for the black developing assembly, and paper deck pedestal lifter control. Hydraulic schematics are included for corona bias switching, power supply distribution across DC controller and motor driver circuits, and high-voltage transformer output selection based on copy mode parameters.

Steering component information is provided for No. 1 and No. 2 registration roller positioning, delivery feeder motor control of paper deflector plates during two-sided and overlay copying, and lower feeder assembly set-back mechanism operation when stacking multiple sheets in preparation for second-side copying.

The document includes torque specifications for the primary corona assembly to ensure proper seal compression uniformity.

Table of Contents Reference: Initial chapters establish general machine description with features and specifications for 220/240V models. Copying process documentation explicates the nine-step image formation block from pre-exposure through drum cleaning. Operation and timing sections detail DC controller electrical architecture, main motor control via pulse-lock signals, scanner motor speed variation based on reproduction ratio, lens motor stepping behavior during DIRECT/REDUCE/ENLARGE selection, and sequence timing tables for standard copying and two-sided/overlay modes. Image formation system coverage includes scanning lamp intensity control responding to AE sensor output, primary and transfer corona current management, pre-transfer corona bias optimization, development bias AC/DC component switching, and blank exposure lamp LED array management across 124 diodes. Pick-up/feeder system documentation covers cassette size identification via tab configuration, lifter motor operation, pick-up roller release solenoid sequences, manual feed assembly control, registration roller horizontal movement, fixing roller temperature monitoring via thermistor and thermal protection circuits, and comprehensive jam detection across 24 sensor points throughout the paper path. Paper deck pedestal sections describe left and right deck motor control, advance pick-up mechanisms to reduce first-copy time, and lifter position sensor feedback loops. Power supply architecture documentation identifies +24VR, +24VU, +12V, and +5V distribution, fuse protection circuits, and lithium battery backup for RAM and calendar IC data retention during power-off conditions. Service mode guidance includes control display screens, I/O display port mapping for all CPU and LSI interfaces, adjustment parameters for light intensity and AE slope, function/inspection mode operations, user option settings, and counter tracking for consumable wear items.

FAQ

Customer Reviews

Read what our customers say about this Canon Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)