1993 Canon NP6030 Service Manual (374 P.)

Comprehensive electronics diagrams, reproduction ratios, and drum cleaning procedures for NP6030 copier service. Complete technical documentation for OPC drum maintenance and transfer roller bias circuits.

Manual Preview

Sample pages from the 1993 Canon NP6030 Service Manual (374 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Canon NP6030 — 1993 Integrated Handbook for Industrial Dossier Bundle.

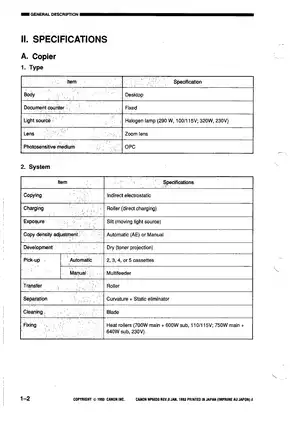

- Calibrated Play Limits: The reproduction ratio corresponds to 49% through 204% in 1% increments Architecture.

- Rated Electrical Specs: Main scanning lamp is calibrated to 290 W (100/115V) and 320 W (230V) Standards.

- Published Climate Specs: Operating temperature range determines 5°C to 32.5°C for optimal machine function Margin.

- Authorized Travel Rate: The wait period sets 30 seconds or less at 20°C or more during initial warm-up Protocol.

- Maximum Print Quality: Ozone generation is specified as 0.01 ppm or less; 0.02 ppm or less maximum output Norms.

- Documented Spacing Data: Paper stack capacity reaches 2550 sheets (500-sheet cassette plus 50-sheet multifeeder) Parameters.

Professional Workshop Service Manual & Technical Specifications

Technical Troubleshooting Safety Manual: Copier Official Canon NP6030 Copier Service Manual - Repair & Diagnostics (1993) Logic-Archive

Application-Range: Canon NP6030 (1993) // Conceptual-Layout: electrostatic / imaging / optical Systems // Machine-Range: desktop copying device specifications.

| Assessment-Parameter | Technical-Path | Architecture |

|---|---|---|

| Exposure and transfer mechanisms | Documented system components | Image formation outlined |

| Scanning, charging, and development | Process-control circuits included | Electrical signal routing |

| Paper handling and registration | Sensor placement specifications | Mechanical path integration |

Factory procedures are documented for the copying process, establishing the drum cleaning assembly, describing the development system, covering transfer and separation mechanisms, and addressing fixing and delivery operations. The manual outlines the exposure system architecture alongside electrical circuit controls for the primary charging roller, organizing scanning operations with detailed sequencing for multiple reproduction modes, and presenting jam detection protocols integrated with protection mechanisms.

Adjustment procedures are detailed for optical exposure and scanning lamp intensity, providing guidance on primary charging roller bias calibration and transfer roller efficiency control to ensure optimal image formation. Timing procedures are documented for main motor operations and scanner movement coordination, establishing sequences for both standard and specialty copying modes including two-sided and overlay configurations. Technical notes are provided for developing assembly toner supply systems, waste toner monitoring through sensor activation, and blank exposure control using shutter mechanisms to manage non-image areas. Quality checks are addressed for automatic exposure adjustment and document size identification using sensor-based detection, along with paper feeding verification across cassette and multifeeder systems. The service procedures section documents torque specifications for component assembly to ensure proper oscillation integrity.

The manual provides comprehensive electrical circuit documentation including input sensors (paper detection, position monitoring, thermal feedback), output controls (motor drivers, solenoid activation, heater regulation), and communication protocols between the DC controller PCB and composite power supply PCB. Sequence timing diagrams establish operational phases from power-on through warm-up rotation, initial drum stabilization, scanning operations, transfer procedures, and final delivery cycles. The document references paper size identification through cassette sensors, multifeeder width detection, and automatic cassette selection based on document dimensions.

Specifications included: Photosensitive drum construction (organic photo conductor with aluminum base), developing cylinder voltage parameters, transfer bias constant voltage maintenance, static eliminator bias switching, fixing roller temperature control in normal and low-temperature modes, and cleaning belt solenoid activation frequency based on copy paper length.

FAQ

Customer Reviews

Read what our customers say about this Canon Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)