2007 Canon PIXMA MP970 / MP610 / MP600 Service Manual

Error codes, component removal sequences, and ink absorber replacement for MP970 multifunction printer. Service mode diagnostics, carriage alignment, and paper feed troubleshooting—QY6-0062-010, QM3-2237-000.

Manual Preview

Sample pages from the 2007 Canon PIXMA MP970 / MP610 / MP600 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Canon PIXMA MP970 (QY6-0062-010) — 2007 Technical Reference Handbook | MP970 Multifunction Set.

- Authorized Twist Specifications: For optimal fastening, 113 N·m (83 lb-ft) is configured at the blade cap screw fastening requirement Sequences.

- Critical Capacity Limits: Primary power configuration is established at 100V 50/60Hz, 120V 60Hz, 220V 50Hz, or 240V 50Hz — represents international voltage compatibility Baseline.

- Operational Measurement Bounds: For optimal circuitry protection, 5 Amps (100-127V) and 2.5 Amps (220-240V) limits the minimum recommended circuit capacity Requirements.

- Fundamental Environmental Range: Maximum internal temperature is specified to exceed 5B00–5B01 service error codes when the ink absorber reaches full capacity — indicates critical maintenance Threshold.

- Specific Rotation Data: The paper feed motor maintains belt tension adjustment at replacement intervals with standard grease application of 200–400 mg (Floil KG-107A) per carriage shaft location Mapping.

- Core Moment Values: Service mode operation indicates multiple correction protocols: LF/Eject correction spanning Pattern Nos. 0–2, automatic print head alignment tolerances, and ink absorber counter values ranging 0–100% Configuration.

Professional Workshop Service Manual & Technical Specifications

Operational Service Manual: Printer Comprehensive Service & Repair Manual: Canon PIXMA MP970, MP610, MP600 All-In-One Inkjet Printer (2007) Parts-Reference

Equipment-Series: Canon PIXMA MP970, Canon MP970, Canon MP610, Canon MP600 // System-Identifier: Multifunction Printer / Inkjet Systems Logic // Design-Core: Maintenance, Repair, and Technical Service Framework.

| Category | Value | Documentation |

|---|---|---|

| Document Scope | Service and Maintenance Procedures | Comprehensive coverage of all service modes |

| System Coverage | Print engine, Scanning, Paper feed, Carriage mechanisms | Complete component specifications provided |

| Technical Operations | Error diagnostics, Adjustment protocols, Verification testing | All procedures documented with detailed steps |

Outlining the operational framework across Print Head Replacement and Ink System Configuration, the manual encompasses Carriage Movement Compensation, Scanner Unit Integration, and Logic Board Initialization, providing comprehensive reference data for all preventive and corrective service operations.

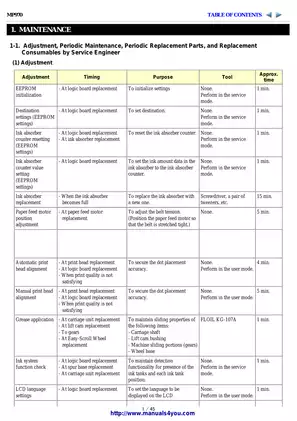

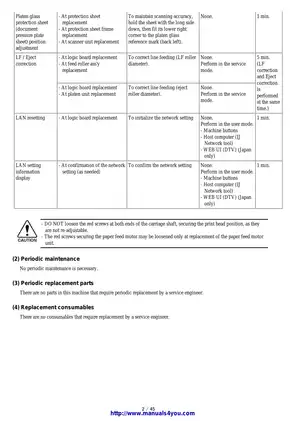

Inspection guidelines are provided for error display indications, operator call errors, and service call errors, documenting the LED signal sequences and corresponding error codes that identify mechanical and electrical faults. The document includes detailed operator maintenance procedures for print head cleaning, ink tank installation, paper feed roller maintenance, and scanning area preparation. Alignment specifications are included for carriage positioning, document pressure plate sheet installation, and the automatic print head alignment sensor correction process. Reference data is included for EEPROM initialization, destination settings, ink absorber counter management, and service mode parameter configuration. The manual covers specialized adjustment procedures for paper feed motor belt tension, grease application to sliding portions and gear mechanisms, and the correction protocols for line feed and eject roller diameter compensation.

Diagnostic procedures are covered for troubleshooting faulty operations including power management failures, carriage movement interference, scanning signal errors, print quality issues, and network connectivity problems. The document includes service test print samples, ink absorber counter value documentation, and EEPROM information output formats. Additional technical data encompasses parts catalog identification, housing removal procedures, cable wiring layout diagrams, scanner lock mechanism operation, and the bottom case separation process for purge unit access. The manual documents torque specifications for the fasteners to ensure proper assembly and mechanical integrity.

| Chapter Content | Reference Data | Coverage |

|---|---|---|

| Maintenance | Adjustment, periodic inspection, replacement parts | Service Engineer and Customer procedures |

| Error Messages | Display codes, alarm sequences, troubleshooting solutions | Operator and Service call error definitions |

| Repair Procedures | Component replacement, disassembly notes, grease application | Special handling for sensitive parts |

| Adjustments | Print head alignment, ink absorber settings, LF/Eject correction | Service mode operation with LED navigation |

| Verification | Test print output, counter value documentation | Operational confirmation post-repair |

FAQ

Customer Reviews

Read what our customers say about this Canon Printer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)