Canon C2050/C2020/iR C2100/C2100S Service Manual 576P

Color imageRUNNER service procedures for scanner/printer units — drum drives, transfer belt assembly, fixing system, and sheet feed mechanisms. Reference FY8-23B9-000.

Manual Preview

Sample pages from the Canon C2050/C2020/iR C2100/C2100S Service Manual 576P manual

Purchase & Download

Models Covered & Key Technical Specifications

Canon imageRUNNER C2050, C2020, iR C2100, iR C2100S — 2000 Consolidated Mechanical Reference | imageRUNNER Series Record.

- Maximum Package Size: The copyboard glass dimensions are specified at 216 × 297 mm (AB size) with alternative configurations reaching 279 × 432 mm (A4 paper) for handling Architecture.

- Authorized Native Resolution: For optimal image reproduction, the CCD optical unit achieves 15-pixel main scanning adjustment range indicating high-precision positioning Norms.

- Established Threaded Fastener Data: Scanner motor drive system specifies 66-tooth timing belt with stepped M4×6 setscrew mounting as the standard fastening Bounds.

- Measured Alignment Specs: The image write start position requires calibration within −48 to +48 pixel range in main scanning direction to correct color displacement Topology.

- Critical Thermal Limits: Fixing main heater operates at 190°C controlled operation with 180°C sub-heater setting, maintaining maximum threshold of 245°C (hardware) or 240°C (software) Matrix.

- Rated Net Mass: Scanning lamp assembly requires 500-hour life expectancy rated at 75,000 scans before replacement, indicating consumable durability Standards.

Professional Workshop Service Manual & Technical Specifications

Full-Coverage Reference Manual: Copier 2000 Canon C2050 C2020 C2100 C2100S Service Manual (587 P.) Procedure-Library

Machine-Range: Canon imageRUNNER C2050, C2020, iR C2100, iR C2100S // System-Coverage: Comprehensive Digital Copier System Architecture / Multifunction Device Logic // Diagnostic-Area: Complete Electrical and Mechanical Component Reference Data.

| Component System | Documentation Scope | Technical Detail |

|---|---|---|

| Reader Unit Imaging | Scanning lamp assemblies, CCD optical units, mirror positioning systems | Includes CCD adjustment values, optical alignment specifications |

| Printer Unit Formation | Drum units, transfer systems, fixing assemblies, paper feed mechanisms | Comprehensive component location diagrams, assembly procedures |

| Electrical Control | Reader controller PCB, DC controller PCB, system controller PCB, power supply units | PCB connector listings, circuit diagram references, I/O signal specifications |

Featuring a modular arrangement of maintenance procedures, calibration methodologies, electrical component diagnostics, sensor operation protocols, and mechanical assembly documentation, this manual comprehensively addresses the Canon C2050, C2020, iR C2100, and iR C2100S copier platforms across both reader and printer subsystems.

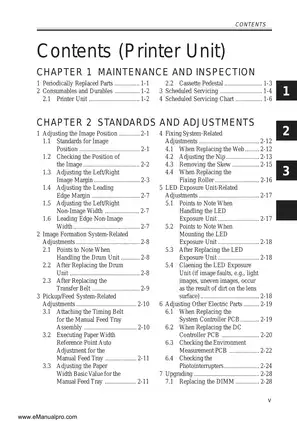

The document includes detailed information on scheduled servicing intervals, consumable replacement parts, and periodically maintained assemblies. Reference data is included for image positioning standards, including horizontal registration adjustments, leading edge margin specifications, and non-image width parameters. Alignment specifications are included for scanner-related adjustments, including scanning lamp intensity control, CCD unit positioning, and optical reader leveling procedures.

Reference data is included for electrical component operations, including photointerrupter checks, fan operation verification, motor function assessment, solenoid activation testing, clutch engagement diagnostics, and thermistor threshold monitoring. Wiring diagrams are provided for the reader unit general timing circuit, printer unit general circuit topology, and cassette pedestal electrical connections, documenting signal flow across DC controller PCB, serial driver PCB, and system controller PCB interfaces.

This manual documents torque specifications for mechanical fastener assemblies to ensure proper bolt fatigue prevention across drum motor mounting points, transfer assembly installation, and paper feed drive coupling systems.

The document provides comprehensive service mode operation guidance, covering display functions (sensor status, jam records, error code history), I/O signal monitoring (input/output address mapping, sensor state verification), adjustment parameters (image registration, density control, developer concentration), functional testing (motor and clutch operation, high-voltage output, LED exposure checks), settings configuration (machine options, user preferences, accessory parameters), test print generation (reference patterns, halftone grids, gradation strips), and counter tracking (parts usage, copy counts, maintenance intervals).

Error code documentation spans self-diagnosis mechanisms for the copier unit, DADF feeder assembly, finisher units, saddle stitcher subsystems, sorter mechanisms, and PDL network board, with detailed fault condition specifications and detection methodology for electrical, mechanical, and communication system failures across all machine subsystems.

FAQ

Customer Reviews

Read what our customers say about this Canon Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)