KYMCO Agility 125 Service Manual (192 Pages)

Complete maintenance and repair guide covering engine, fuel system, electrical, chassis, brakes, suspension, and emission control systems with full specifications and torque values.

Manual Preview

Sample pages from the KYMCO Agility 125 Service Manual (192 Pages) manual

Purchase & Download

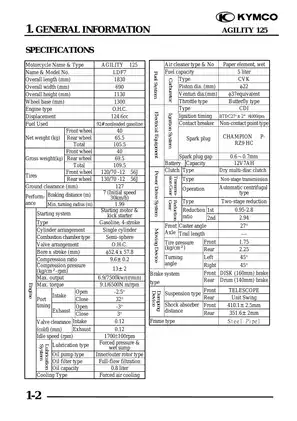

Models Covered & Key Technical Specifications

KYMCO Agility 125 (LDF7) — 2005–2012 Strategic Specification Toolkit | Agility 125 Series Repository.

- Published Angular Speed: 6900 rpm is rated at the maximum rated engine output Bounds.

- Specific Enclosure Specs: For optimal displacement, 124.6 cc establishes the cylinder volume Topology.

- Integral Native Resolution: 52.4 mm — supports the piston bore diameter Matrix.

- Operational System Volume: The fuel tank requires 5.0 liters for standard fuel capacity Standards.

- Established Consumption Data: Compression pressure achieves 13 ±2 kg/cm² within rpm Margin.

- Authorized Travel Rate: Maximum torque output governs 9.1 N·m at 6500 rpm Protocol.

Professional Workshop Service Manual & Technical Specifications

Specialized Training Manual: KYMCO Agility 125 Scooter Service and Repair Documentation Repository

Equipment-Series: KYMCO Agility 125 LDF7 (Model 125cc) // Architecture-Focus: Single-cylinder four-stroke engine with CVT transmission system // Equipment-Series: Complete service procedures spanning engine, electrical, chassis, and emission control systems.

| Document Section | Overview | Reference Material |

|---|---|---|

| Engine Systems | Cylinder head, valves, piston assemblies, lubrication circuit | Complete specifications provided |

| Electrical Components | Battery, charging system, ignition, starting motor | Complete testing procedures documented |

| Chassis Assembly | Wheels, brakes, suspension, steering geometry | Service limit data included |

Correctly requiring systematic organization, the document outlines procedures for engine removal and installation, covering frame-mounted accessibility points. The manual presents comprehensive data addressing cylinder head assembly with valve rocker arms and camshaft holder configurations, alongside crankcase separation methodology. Electrical system documentation covers battery charging protocols, regulator/rectifier circuit inspection, and A.C. generator testing with coil resistance specifications. Suspension service documentation covers front fork ball race replacement, shock absorber damper rod removal, and steering stem cone race installation sequences, incorporating detailed inspection criteria for bearing clearances and spring free-length measurement protocols.

Calibration requirements are specified for carburetor idle speed adjustment, establishing reference marks on the flywheel for ignition timing verification. The document references torque specifications for the cylinder head nut assembly (2.0 kg-m), drive face nut (5.5-6.5 kg-m), and frame-critical fasteners including steering stem lock nut (6.0-8.0 kg-m), with complete tabulated values for standard and specialized fastener grades. Disassembly instructions are documented for drive and driven pulleys, clutch systems, and final reduction gear assemblies, incorporating removal sequence diagrams and component-level inspection checkpoints. Wear limits are specified for connecting rod big-end clearance (0.55mm service limit), brake drum interior diameter (131mm), and valve guide internal dimensions, establishing replacement thresholds throughout the powertrain.

The manual documents torque specifications for the drive and driven pulley systems to ensure proper friction contact and clutch engagement reliability. Troubleshooting matrices are included for engine starting failures, charging system undercharge conditions, brake performance degradation, and steering response anomalies, mapping probable causes to inspection procedures. Cable and harness routing diagrams indicate wire placement along the frame perimeter, specifying band clamp locations and identifying heat-sensitive component avoidance zones. Exhaust emission control system content addresses secondary air cleaner filtration function, air injection cut-off valve vacuum actuation thresholds (250mm/Hg), and reed valve stopper clearance documentation (6.6mm).

The manual provides comprehensive lubrication point mapping for engine components including cam lobes, valve rocker arm friction surfaces, crankshaft seal lip areas, and transmission gear engaging surfaces. Fuel system documentation encompasses carburetor float level inspection (17.0mm), pilot screw opening reference (3±1/2 turns), and fuel strainer arrow orientation alignment during installation, with complete vacuum tube and cable routing diagrams. Lighting and instrument content includes handlebar switch continuity tables, fuel gauge resistance specifications (upper position 30-686Ω range), and spark plug gap tolerance parameters (0.6-0.7mm). Maintenance schedule tables establish service intervals at 300km, 1000km, and 2000km increments, designating replacement, cleaning, adjustment, and inspection operations across all major component families.

Metadata labels: Equipment-Series (KYMCO Agility 125 LDF7); Architecture-Focus (four-stroke single-cylinder CVT scooter with integrated emission control); Equipment-Series (service manual for technician reference).

FAQ

Customer Reviews

Read what our customers say about this Kymco Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)