2004-Present KYMCO Agility 50 Service Manual (183 P.)

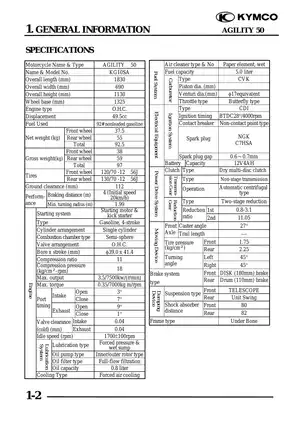

49.5cc 4-stroke OHC engine service data — cylinder head/piston clearance 0.04mm, ignition timing 28° BTDC, SAE 15W-40 engine oil specifications. Publication KG10SA

Manual Preview

Sample pages from the 2004-Present KYMCO Agility 50 Service Manual (183 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

KYMCO Agility 50 — 2004–Present Strategic Database for Agility 50 Dossier.

- Published Production Rate: Engine displacement reaches 49.5 cc is specified as the cylinder volume Bounds.

- Specific Physical Specs: For optimal performance, 3.5 kW at 7500 rpm is rated at the maximum power output Topology.

- Approved Output Quality: Maximum torque of 0.35 kg·m governs the crankshaft rotation at 7000 rpm Matrix.

- Reference Fill Levels: The fuel tank capacity establishes 5.0 L (1.3 US gal) for operational margin Standards.

- Established Assembly Gap: Valve clearance sets 0.04 mm for both intake and exhaust cold lash Protocol.

- Authorized Print Rate: Compression pressure reaches 18 kg/cm² (256 psi) is designed for combustion chamber efficiency Margin.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Technical Manual: Scooter KYMCO Agility 50 (2004-Present) Workshop-Compendium

Engineering-Metrics: KYMCO Agility 50 (2004–present) // Technical-Scope: Service procedures and maintenance systems logic // Equipment-Series: Comprehensive electrical and mechanical specifications.

| Document Category | System Coverage | Reference Material |

|---|---|---|

| Maintenance Framework | Scheduled servicing by mileage intervals | Complete specifications provided |

| Component Systems | Engine, transmission, chassis, electrical | Documentation included for each section |

| Diagnostic Reference | Troubleshooting flowcharts and inspection points | Documented procedures available |

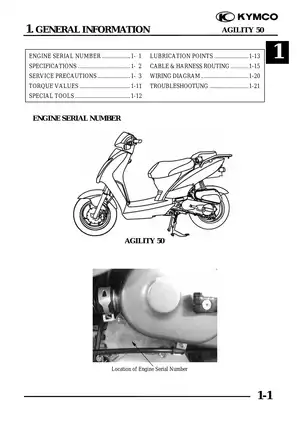

Maintenance information covers engine systems with valve clearance and combustion chamber data, advance timing and ignition sequences, lubrication pathways for crankshaft and connecting rod components, fuel system operation including carburetor adjustment and float chamber assembly, and transmission final reduction gear specifications. Installation guidelines are provided for frame covers, exhaust muffler attachment, cylinder head and camshaft positioning, piston ring installation procedures, and brake component assembly. Technical inspection procedures include compression testing methodology, brake drum and lining measurements, wheel bearing runout assessment, shock absorber spring tension evaluation, and steering head bearing adjustment parameters.

The document describes service operations for the 49.5cc single-cylinder, four-stroke engine incorporating CDI electronic ignition and centrifugal automatic clutch transmission with two-stage reduction gearing. Included are detailed specifications for the carburetor venturi diameter, float level calibration, main and slow jet sizing, and pilot screw opening positions. Wiring diagram routing includes cable harness pathways for throttle control, brake hydraulic systems, speedometer drive cables, and electrical component connectors. The manual documents torque specifications for engine fasteners including cylinder head bolts, oil filter screen cap, exhaust muffler lock bolts, and clutch outer nuts to ensure proper thread engagement security.

OEM guidelines are included for the periodic maintenance schedule spanning initial 300 km service through 12,000 km intervals, designating replacement points for engine oil and filter screen, fuel filter, and gear oil at specified mileage markers. Service tables identify inspection requirements for spark plug condition, valve clearance tolerance, carburetor idle speed adjustment, brake system free play, tire pressure by rider configuration, and suspension damping assessment. The manual provides complete component identification for lubrication points requiring engine oil application on valve guides, cam lobes, piston pin surfaces, and bearing assemblies, plus high-temperature grease allocation for wheel bearings, brake components, and suspension pivots.

Cataloging major assemblies into functional systems, the document covers cylinder head and valve train including intake and exhaust port timing, rocker arm specifications, and valve spring free length limits; drive and driven pulley systems detailing clutch lining thickness, weight roller dimensions, and belt width tolerances; final reduction incorporating gear meshing, bearing inspection, and transmission case cover assembly; and battery charging system with A.C. generator coil resistance values, regulator/rectifier voltage testing, and charging current specifications. Front suspension documentation includes steering head bearing cone race replacement, shock absorber tube assembly with damper rod configuration, brake caliper piston sealing, and brake master cylinder pressure integrity. Rear suspension procedures address shock absorber spring compression, brake drum lining contact surfaces, and rear wheel axle alignment requirements.

FAQ

Customer Reviews

Read what our customers say about this Kymco Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)