1995 Sea-Doo SP/SPI/SPX/GTS/GTX/XP Shop Manual (618 P.)

Complete shop documentation covering Bombardier Rotax 587, 657X, and 717 engines. Comprehensive service procedures for all drivetrain, electrical, and fuel system components. PN 219800016-219800018

Manual Preview

Sample pages from the 1995 Sea-Doo SP/SPI/SPX/GTS/GTX/XP Shop Manual (618 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Bombardier Sea-Doo 1995 SP, SPI, SPX, GTS, GTX, XP (5873, 5875, 5874, 5815, 5863, 5857) — 1995 Technical Mechanical Overview | Sea-Doo Watercraft Engineering Blueprint.

- Integral Displacement Data: Engine displacement reaches 580.7–650 cm³ (35.4–39.67 in³) establishing the cylinder volume Play Limits.

- Measured Power Output: For optimal performance, 106–109 hp at 6200 rpm specifies the maximum rated horsepower Electrical Specs.

- Primary Torque Specification: Peak torque reaches 145 N·m (107 lb-ft) at 5000 rpm corresponds to crankshaft output Climate Specs.

- Essential Compression Ratio: Corrected compression ratios of 5.9:1 to 6.4:1 dictate combustion chamber efficiency Travel Rate.

- Baseline Fuel Capacity: Tank volume ranges from 34–45 L (9–12 US gal) is standardized to fuel system requirements Print Quality.

- Established Cooling Temperature: Monitoring beeper activation threshold limits engine temperature to 96–99°C (205–210°F) Spacing Data Configuration.

Professional Workshop Service Manual & Technical Specifications

Integrated Training Manual: Personal Watercraft (PWC) Shop Manual for ´95 Sea-Doo SP, SPI, SPX, GTS, GTX, XP Watercrafts Technical-Briefing

Model-Portfolio: 1995 SP (5873), SPI (5875), SPX (5874), GTS (5815), GTX (5863), XP (5857) // Specification-Class: Multi-engine propulsion documentation / jet pump system logic // Asset-ID: Comprehensive 630-page factory service resource.

| Integrated-Framework | Rating | Architecture |

|---|---|---|

| Engine Systems | Complete | 587, 657 X, 717 Rotax two-stroke engines with rotary valve induction |

| Propulsion Coverage | Complete | Jet pump assembly, drive shaft, impeller housing, reverse system documented |

| Electrical Schematics | Included | Magneto, CDI ignition, charging system, starting system diagrams |

| Fuel & Lubrication | Documented | Carburetor circuits, oil injection pump, system pressurization procedures |

| Steering & Control | Complete | Nozzle alignment, VTS variable trim motor documentation |

| Body & Hull Repair | Included | Gelcoat procedures, painting specifications, decal installation reference |

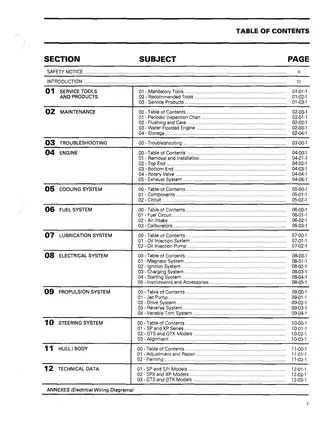

The repository is divided into engine and propulsion sections, cooling and fuel system modules, lubrication and electrical frameworks, and steering and body assemblies. It encompasses the jet pump module, documents the propulsion drive system, and covers variable trim operation with electrical wiring diagrams across all model configurations.

Wear limits are specified for piston-to-cylinder clearances and connecting rod bearings across the three engine families. System operation descriptions cover cooling circuit flow from the jet pump through the water-injected tuned pipe and engine jackets, with calibrated outlet fittings that establish proper thermostat-free temperature control. The documentation addresses magnetic field generation in the NIPPONDENSO CDI system, including generating coil output specifications and ignition timing procedures referenced to Top Dead Center. Assembly instructions are detailed for crankshaft bearing installation using heated bearing seats, rotary valve shaft positioning with specific degree markings, and impeller removal using specialized puller tools with rotating movements. Hydraulic schematics are included for the variable rate oil injection pump with preliminary and final synchronization steps aligned to throttle cable adjustment.

The manual documents torque specifications for the magneto flywheel to ensure proper vibration dampening. Sections systematically explore cylinder head cover removal on the 587 engine, impeller wear ring clearance measurement procedures, and reverse system cable tensioning on GTS and GTX models. Throughout the 630-page technical resource, detailed specifications reference component identification by PIN number, exploded view assemblies showing typical construction details without exaggeration of exact shapes, and comprehensive troubleshooting tables that address starting failures, overheating conditions, and abnormal propulsion system noise. The manual provides factory maintenance intervals, flushing procedures for salt water operation, storage protocols for extended periods, and testing procedures using Bombardier diagnostic equipment and standard automotive tools.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)