1997 Sea-Doo SP/SPX/GS/GSI/GSX/GTS/GTI/GTX/XP/HX Service Manual (428 P.)

Factory service documentation covers 717D (66 kW), 717 (70 kW), 787 (82 kW), and 947 (110 kW) engines with complete maintenance, troubleshooting, and rebuild procedures for all 1997 Sea-Doo watercraft models.

Manual Preview

Sample pages from the 1997 Sea-Doo SP/SPX/GS/GSI/GSX/GTS/GTI/GTX/XP/HX Service Manual (428 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo SP, SPX, GS, GSI, GSX, GTS, GTI, GTX, XP, HX — 1997

Procedural Guide & Technical Directory Record.

- Published Production Rate: The 717D engine corresponds to 717 cm³ (43.7 cu in) displacement volume Margin.

- Measured Physical Specs: Crankshaft assembly fasteners sets 95 N·m (70 lbf·ft) torque requirement Protocol.

- Approved Output Quality: Peak horsepower is rated at 110 kW (147 hp) for the 947 engine Architecture.

- Reference Fill Levels: Standard fuel tank volume achieves 48 liters (12.7 US gallons) capacity Norms.

- Fundamental Assembly Gap: Impeller shaft radial play determines 0.05 mm (.002 in) maximum tolerance Bounds.

- Universal Print Rate: Oil injection pump delivery yields 4.5 mL per 100 engine revolutions Topology.

Professional Workshop Service Manual & Technical Specifications

Specialized Reference Training Manual: Personal Watercraft (PWC) 1997 Sea-Doo Service Manual: SP 5879 / SPX 5834 / GS 5821 / GSI 5822 / GSX 5624 / GTS 5818 / GTI 5841 / GTX 5642 / XP 5662 / HX 5882 Repair-Index

Maintenance-Category: Sea-Doo SP, SPX, GS, GSI, GSX, GTS, GTI, GTX, XP, HX models // Architecture-Focus: 2-stroke engine / Jet pump propulsion // Series-Validation: 717D, 717, 787, 947 engine configurations with rotary valve intake control systems.

| Performance-Element | Operational-Logic | Architecture |

|---|---|---|

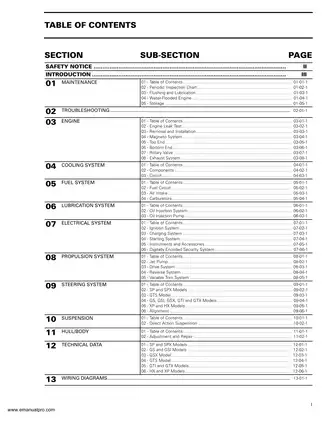

| Engine Systems | Rotary valve timing procedures, magneto CDI ignition, top end/bottom end overhaul | Complete specifications provided |

| Fuel & Lubrication | Mikuni carburetor adjustment, oil injection pump calibration, fuel system pressurization | See Chapter 5-6 |

| Propulsion Assembly | Impeller clearance measurement, wear ring replacement, drive shaft alignment | Documented in Chapter 8 |

| Electrical Components | DC-CDI ignition timing, charging system testing, starter motor disassembly | Complete diagnostic procedures |

| Cooling Architecture | Serial cooling circuit, water flow regulator valve calibration, RAVE system | Chapter 4 specifications |

Outlining the operational framework across maintenance procedures, the document addresses troubleshooting protocols, specifies engine configurations, details fuel system components, and catalogs propulsion mechanisms with systematic cross-referencing throughout all technical chapters.

Quality checks are addressed for cylinder head torque sequences, piston ring gap measurements, and crankshaft deflection tolerances across all displacement variants. The engine section documents complete disassembly procedures for 717 cm³ and 787 cm³ powerplants, including specialized tooling requirements for magneto flywheel removal and rotary valve timing verification. Cooling system maintenance is addressed in dedicated chapters covering water injection fitting calibration, temperature sensor diagnostic procedures, and tuned pipe pressurization testing protocols.

The troubleshooting chapter addresses diagnostic flow charts for ignition spark verification, fuel delivery problems, and starting system failures with resistance value specifications. Testing requirements are specified for battery charging coil output, trigger coil continuity, and MPEM self-diagnostic modes using Bombardier ignition tester equipment. The propulsion system documentation includes impeller/wear ring clearance specifications with maximum 1.0 mm tolerance limits, jet pump housing pressurization procedures at 70 kPa, and drive shaft deflection measurement techniques.

The manual documents torque specifications for the crankshaft assembly to ensure proper thermal expansion compensation, with values ranging from 24 N•m for cylinder head fasteners to 145 N•m for magneto flywheel retention across different engine configurations.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)