2001 Sea-Doo GS/GTS/GTI/GTX/RX/XP Service Manual (505 Pages)

Complete shop manual covering 717/787 RFI/947 engines with fuel injection, RAVE valve systems, cooling circuits, and full electrical schematics for all 2001 Sea-Doo PWC models.

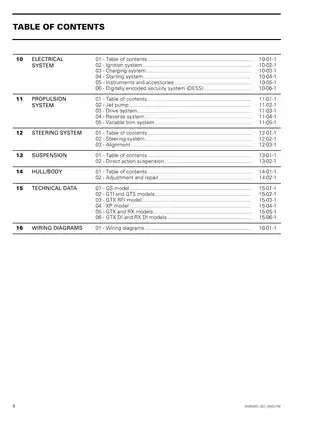

Manual Preview

Sample pages from the 2001 Sea-Doo GS/GTS/GTI/GTX/RX/XP Service Manual (505 Pages) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo GS, GTS, GTI, GTX, GTX RFI, GTX DI, RX, RX DI, XP — 2001 Technical Service Vault | Sea-Doo Series Repository.

-

Calibrated Engine Displacement Data: 717 cc (44 cu in) specifies the single-cylinder two-stroke engine architecture for GS, GTS, and GTI base models, establishing fundamental power generation specification Architecture.

-

Measured Power Output: For optimum watercraft performance, 110 hp (82 kW) maximum engine output is rated on GTX RFI models representing peak crankshaft horsepower Framework.

-

Primary Torque Specification: The counterbalance shaft gear cavity requires 30 mL (1 oz) SAE 30 motor oil fill capacity at 110 N•m (81 lbf•ft) magneto flywheel torque Bounds.

-

System Fuel Capacity: GTX DI model fuel tank yields 50 L (13.2 US gal) total reservoir volume for extended high-performance operation Topology.

-

Core Water Temperature Threshold: The cooling system overheat warning activates at 94°C (201°F) maximum operating temperature protecting internal engine components Matrix.

-

Standard Crankcase Sealant Protocol: Crankcase assembly requires Loctite 5910 silicone-based sealant applied uniformly at 4-24 hour curing interval with 10-minute assembly window Standards.

Professional Workshop Service Manual & Technical Specifications

Technical Safety Service Manual: Personal Watercraft (PWC) 2001 Sea-Doo Specification-Set

Engineering-Metrics: Sea-Doo GS, GTS, GTI, GTX, GTX RFI, GTX DI, RX, RX DI, XP — 2001 // Serial-Range: Complete model coverage 717, 787 RFI, 947 engines // Year-Coverage: 2001 factory service documentation, 505 pages.

| Service-Nexus | Rating | Calibration-Standards |

|---|---|---|

| Engine Systems (717, 787 RFI, 947) | Complete coverage | Specification data provided |

| Fuel Injection (RFI and DI) | Electronic management maps | Sensor resistance values documented |

| Propulsion Assembly | Jet pump and drive systems | Alignment procedures included |

| Electrical & Ignition | DESS, charging, starting | Wiring diagrams included |

| Cooling & Exhaust | Thermal management | RAVE valve operation documented |

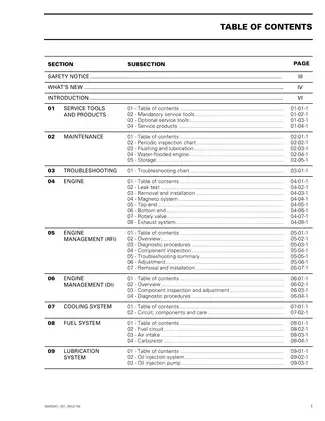

Maintenance information covers engine flushing protocols and seasonal storage procedures, provides carburetor adjustment references for applicable models, addresses water-flooded engine recovery steps, and documents the cooling system flushing sequence with engine internal lubrication. Disassembly procedures encompass magneto systems across all engine families, top-end cylinder and piston service, bottom-end crankshaft assembly, rotary valve timing mechanisms, and exhaust manifold configurations. The manual documents torque specifications for the fastener systems to ensure proper structural integrity.

Suspension service documentation covers direct action suspension geometry and adjustment parameters, steering system alignment procedures, and hull/body repair methods with adjustment sequences. Propulsion section reviews jet pump construction including impeller clearance measurement, drive shaft boot condition assessment, and variable trim system operation across model variations. System operation descriptions cover fuel delivery circuits for carburetor-equipped, RFI, and DI injection platforms, lubrication systems with oil pump adjustment reference data, and electrical system topology including ignition timing management.

The documentation addresses engine management diagnostics for both RFI (Rotax Fuel Injection) and DI (Direct Injection) systems, component inspection procedures for sensors and actuators, throttle body synchronization on twin-throttle configurations, and air compressor pressure testing methodology. Troubleshooting summary identifies fault code interpretation, drowned engine recovery procedures, and limp-home operational modes. Technical data tables include combustion chamber volume specifications by engine family, piston-to-cylinder wall clearance measurements, ring end gap tolerances, and bearing inspection criteria across 717, 787 RFI, and 947 engine platforms.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)