2002 Sea-Doo GTI/LE GTX/RFI RX/DI XP/LRV DI Shop Manual

Documents fuel injection, ignition timing, air compressor, and exhaust system service procedures for 717/787/947 engine displacements across all 2002 Sea-Doo PWC models.

Manual Preview

Sample pages from the 2002 Sea-Doo GTI/LE GTX/RFI RX/DI XP/LRV DI Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo GTI, GTI LE, GTX, GTX RFI, XP, RX, RX DI, LRV DI — 2002 Systematic Expert Registry | PWC Series Suite.

- Factory Threaded Fastener Data: 24 N·m (18 lbf·ft) is calibrated to cylinder head M8 screw fastening requirement Mapping.

- Essential Fluid Levels: 386–414 kPa (56–60 PSI) governs fuel pressure regulation framework Configuration.

- Key Deviation Limits: 1.1 mm (0.043 in) spark plug gap is specified as ignition framework for carbureted Rotax engines Benchmarks.

- Primary Operating Temps: 0.40–0.80 ohm stator resistance supports charging framework on RFI and DI models Range.

- General Angular Speed: 2.0 liters (68 oz) oil tank capacity provides Rotax 947 lubrication system operation Sequences.

- Integral Rotational Force: 718.2–951.2 cc engine displacement is rated at marine power plant architecture Baseline.

Professional Workshop Service Manual & Technical Specifications

Precision Installation Reference Manual: Sea-Doo GTI/GTX/RX/XP/LRV 2002 Shop Manual Engine-Compendium

Product-Line: Sea-Doo GTI, GTI LE, GTX, GTX RFI, XP, RX, RX DI, LRV DI // Operational-Framework: Multi-Engine Service Logic // Product-Line: 717/787/947 Rotax Engine Documentation.

| Metric | Operational-Logic | Calibration-Spec |

|---|---|---|

| Engine Displacement | 717cc / 787cc / 947cc Rotax power plants | Complete displacement values documented |

| Cylinder Head Assembly | Fastener configurations across engine families | Clamp force specifications included (24 N·m reference) |

| Ignition Framework | Carbureted, RFI, and DI system architectures | Spark plug gap reference data (1.1 mm baseline) |

| Stator Resistance | Charging system control parameters | Measured ohm ranges provided (0.40–0.80 ohm) |

| Oil System | Rotax lubrication requirements | Tank capacity specifications (2.0 liters documented) |

| Electrical Connectors | Deutsch joint configurations | Tool-ID 114010 terminal release specifications |

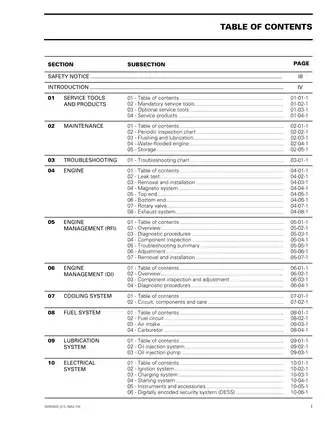

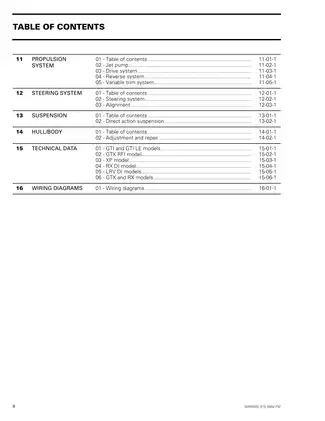

Organized into dedicated modules for Section 01 Service Tools and Products, supplemented by Section 02 Maintenance, engaged by Section 03 Troubleshooting, presented via Section 04 Engine, coordinated through Section 05 Engine Management (RFI), and complemented by Section 06 Engine Management (DI). The manual further encompasses Section 07 Cooling System, detailed in Section 08 Fuel System, integrated within Section 09 Lubrication System, clarified through Section 10 Electrical System, addressed in Section 11 Propulsion System, structured for Section 12 Steering System, organized in Section 13 Suspension, covered in Section 14 Hull/Body, specified under Section 15 Technical Data, and concluded with Section 16 Wiring Diagrams.

Precisely requiring comprehensive coverage, the document addresses both 2-stroke Rotax engine platforms and fuel delivery architectures across carbureted, rotary valve, and modern injection systems. The manual provides methodical procedures for magneto system disassembly, top-end cylinder service, and bottom-end crankshaft inspection. Systematic maintenance guidance encompasses cylinder head cover removal, piston and connecting rod service, and bearing replacement protocols. The publication documents carburetor adjustment, fuel filter maintenance, and oil injection pump synchronization requirements.

Testing requirements are specified for engine leak detection, compression measurement, and ignition timing verification across all model configurations. Clearance measurements are addressed for rotary valve positioning, piston-to-cylinder wall clearance validation, and ring end gap inspection. Special procedures are addressed for RAVE valve (Rotax Adjustable Variable Exhaust) operation, tuned pipe installation, and resonator removal techniques. Verification procedures are included for crankshaft deflection, connecting rod straightness, and fuel system pressure testing.

Reference chapters include detailed component specifications for 717, 787 RFI, and 947 engine families with model-specific torque sequences and assembly diagrams. The manual documents torque specifications for engine fasteners to ensure proper mating surface contact, with values presented in both metric and imperial measurements throughout illustrated exploded views and assembly procedures.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)