2000 Sea-Doo GS/GTI/GTS/GTX/XP Service Manual

Complete engine diagnostics, overhaul procedures, and fuel injection systems for 717/787 RFI/947 powerplants. Factory specifications, torque charts, and maintenance intervals included.

Manual Preview

Sample pages from the 2000 Sea-Doo GS/GTI/GTS/GTX/XP Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo GS, GTI, GTS, GTX, XP, GSX RFI, GTX RFI — 2000 Professional Service Archive | Sea-Doo Series Repository.

- System Energy Draw: 717 engine displacement is standardized to 717 cc (43.7 cu in) cylinder volume Mapping.

- Maximum Temperature Range: For optimal combustion chamber volume, 31.2 - 34.0 cc determines the 717 engine head capacity Configuration.

- Measured Power Output: 160 watts at 6000 RPM is rated at magneto output on GS, GTS, GTI models Benchmarks.

- Published Operational Speed: 7100 ± 50 RPM is calibrated to engine revolution limiter setting for GS and GTI Sequences.

- Authorized Fuel Pressure: Fuel injection pressure achieves 386 - 414 kPa (56 - 60 PSI) regulated delivery Baseline.

- Technical Clamp Forces: Piston-to-cylinder wall clearance corresponds to 0.10 - 0.20 mm (.004 - .008 in) tolerance Range.

Professional Workshop Service Manual & Technical Specifications

Strategic Configuration Training Manual: Personal Watercraft (PWC) 2000 Sea-Doo GS GTI GTS GTX XP GSX RFI Service Manual (805 Pages) Repository

System-Coverage: Sea-Doo GS, GTI, GTS, GTX, XP, GSX RFI, GTX RFI — 2000 model year // Architecture-Focus: Multi-engine fuel injection and traditional carburetor system logic // Reference-Category: Comprehensive technical service procedures with specifications and component guidance.

| Document Section | System-Path | Architecture |

|---|---|---|

| Engine Systems | Magneto, CDI, RFI systems | Complete ignition timing procedures documented |

| Cooling Circuit | Pressurized water injection | Total loss system specifications provided |

| Fuel Management | Carburetor and RFI delivery | Dual-system service protocols included |

| Propulsion Assembly | Jet pump and drive alignment | Wear ring and impeller data documented |

| Electrical Network | MPEM and battery systems | Fault code tables and sensor values included |

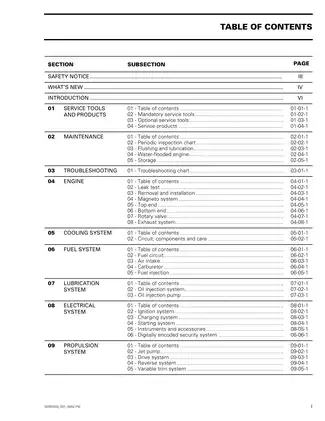

Coverage is segmented into 14 major sections including engine specifications (717, 787 RFI, and 947 displacement engines), maintenance protocols, and diagnostic procedures, systematically addressing magneto systems, cooling arrangements, fuel delivery mechanisms, lubrication requirements, electrical configuration, propulsion architecture, steering geometry, suspension design, hull structure, technical reference data, and wiring documentation that support sequential service workflows without matching original publication sequence.

Repair information is provided for crankshaft alignment verification, compression assessment procedures, connecting rod bearing clearances, and bearing deflection measurement methodologies across bottom-end assemblies. The document includes coverage of cylinder head gasket thickness tables (ranging from 0.3 to 0.8 mm), combustion chamber volume measurement protocols, and piston-to-cylinder wall clearance verification using graduated burette methodology. Brake system specifications are included for jet pump seal replacement intervals, impeller wear ring tolerance data, and drive shaft boot condition assessment at scheduled maintenance points. Safety procedures are documented for proper magneto flywheel removal sequencing, crankcase pressure testing at 34 kPa (5 PSI), and fuel system pressurization confirmation before engine start. Fluid capacities are listed for counterbalance shaft oil (30 mL SAE 30 for 787 RFI, 40 mL for 947 engines), cooling system drain procedures, and oil injection system bleeding verification.

The manual documents torque specifications for critical fasteners throughout engine assembly, including crankshaft nut installation (110 N•m for 717/787 engines, 115 N•m for 947), cylinder head bolt sequencing (24 N•m initial, 40 N•m final for 787 RFI), and intake manifold retention (10 N•m) to ensure proper mechanical integration and corrosion joint prevention. Technical data tables provide engine displacement references (717 cc, 787 cc, 947 cc), generating coil output ratings (160-270 watts depending on model), and fuel injection pressure calibration (386-414 kPa). The procedures section describes ignition timing adjustment protocols using degree wheel methodology, MPEM programmer access for DC-CDI systems, and fixed timing activation procedures for RFI engines. Component inspection protocols address rotary valve clearance verification (0.30 ± 0.05 mm), reed valve petals examination for cracks, starter bearing removal methodology, and battery hydrometer specific gravity assessment (1.265-1.280 range for full charge).

Fundamentally requiring proper hand tools and factory-specified special service tooling, this resource enables systematic diagnosis through multi-stage leak testing, pressure gauge confirmation at fuel rails and engine chambers, resistance measurement of ignition coils (0.41 ± 0.05 Ω primary winding), and sensor verification procedures for throttle position (1.6-2.4 kΩ), crankshaft position (774-946 Ω), air temperature (2.280-2.736 kΩ), and water temperature transducers operating within specified tolerance windows.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)