1998 Sea-Doo Repair Manual: SPX / GS / GSX / XP / GTS / GTI / GTX (426 Pages)

Comprehensive service procedures, parts diagrams, and troubleshooting for Sea-Doo 717/787/947 engines. Detailed coverage of fuel systems, electrical components, jet pump assemblies, and propulsion systems with factory torque specifications.

Manual Preview

Sample pages from the 1998 Sea-Doo Repair Manual: SPX / GS / GSX / XP / GTS / GTI / GTX (426 Pages) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo SPX, GS, GSX Limited, XP Limited, GTS, GTI, GTX Limited — 1998 Manufacturer Sourcebook Registry | Watercraft Documentation Record.

- Prescribed Output Rating: 947 engine produces 110 hp at 6300 rpm represents the maximum rated horsepower Architecture.

- Documented Cooling Specs: For optimal operation, 34 kPa (5 PSI) maintains the pressure test specification Norms.

- Core Print Rate: 787 engine displacement measures 787 cc (48 cu in) as the engine cylinder volume Protocol.

- Rated Precision Specs: The jet pump impeller clearance is measured at 1.0 mm (.040 in) maximum allowable tolerance Bounds.

- Technical Locking Torques: Cylinder head bolts require 34 N•m (25 lbf•ft) for the 947 engine fastening requirement Topology.

- Advanced Load Capacity: Starter nominal output reaches 0.6 kW (12 V rated) for engine cranking specification Parameters.

Professional Workshop Service Manual & Technical Specifications

Enhanced Technical Documentation-Set Manual: Personal Watercraft (PWC) Sea-Doo SPX 5838/5839, GS 5626/5844, GSX Limited 5629/5845, XP Limited 5665/5667, GTS 5819, GTI 5836/5841, GTX Limited 5837/5842 1998

Engineering-Base: SPX, GS, GSX Limited, XP Limited, GTS, GTI, GTX Limited (1998 models) // Subsystem-Focus: Propulsion Logic / Drive Architecture // Engine-Type: 717cc, 787cc, and 947cc Rotax Two-Stroke Systems.

| Document Category | Content Coverage | Reference Details |

|---|---|---|

| Maintenance Procedures | Periodic inspection protocols, lubrication schedules, water-flooded engine recovery | Complete specifications provided |

| Engine Systems | Magneto, fuel delivery, oil injection, cooling architecture | Chapters 04-07 documented |

| Electrical & Starting | Ignition timing verification, charging circuits, DESS security system | Testing procedures included |

| Propulsion Assembly | Jet pump operation, drive shafts, reverse mechanisms, variable trim control | Component diagrams provided |

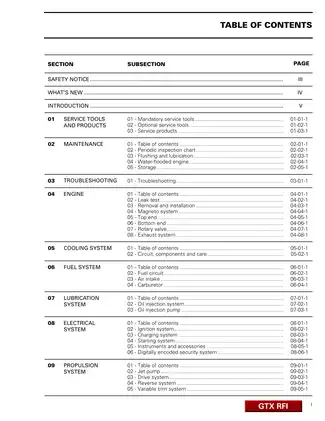

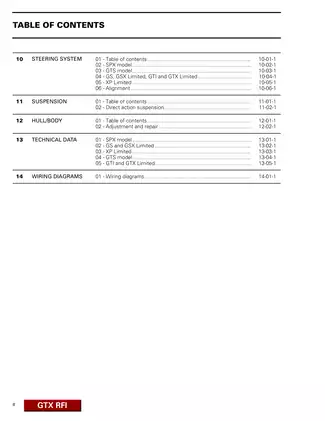

Technical units are distributed across fourteen major sections covering the complete watercraft architecture. The manual addresses engine systems including the magneto assembly, top and bottom end procedures, rotary valve timing, and exhaust configurations, incorporates cooling system circuit descriptions with pre-heated water flow pathways and thermostat-free temperature regulation, examines fuel system layouts featuring carburetor adjustment protocols and fuel filter maintenance, and details the lubrication system oil injection calibration. Electrical system documentation encompasses ignition timing adjustment methodology, charging circuit diagnostics, starter motor specifications, and the digitally encoded security system operation, while propulsion information covers jet pump impeller clearance verification, drive shaft alignment, reverse system mechanical operation, and variable trim system adjustment sequences. The manual provides troubleshooting guidance for engine starting problems, performance issues, and system malfunctions through diagnostic flow charts.

Quality checks are addressed for ignition coil output, battery condition assessment, and fuel system pressurization to ensure proper watercraft operation. The troubleshooting chapter addresses engine misfiring, overheating conditions, propulsion system abnormal noise, and electrical component verification through systematic diagnostic procedures. Cooling system maintenance is addressed in detail with flushing protocols, winterization procedures for regions with freezing temperatures, and antifreeze mixture specifications for safe storage. The document includes torque specifications for fastener assembly to ensure proper component securing across engine mounts, crankcase halves, cylinder head bolts, and jet pump attachments. Technical data sections provide model-specific identification numbers, hull identification number interpretation, and engine identification number location guides for accurate parts ordering and service record documentation.

The manual documents torque specifications for fasteners throughout engine assembly procedures to ensure proper mechanical integrity across all subsystems.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)