1999 Sea-Doo SPX / GSX RFI / GTX / XP Limited Service Manual

Field service reference for 717/787/947 engine systems — fuel injection, carburetor, magneto ignition, jet pump, exhaust, and cooling system. Complete rebuild specifications and diagnostic procedures for all 1999 models.

Manual Preview

Sample pages from the 1999 Sea-Doo SPX / GSX RFI / GTX / XP Limited Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo SPX, GSX RFI, GTX RFI, GS, GTX Limited, XP Limited — 1999 Certified Specification Registry | PWC Series Bundle.

- Approved Angular Speed: Maximum engine RPM reaches 7120 ± 50 rpm corresponds to the electronic rev limiter Margin.

- Baseline Enclosure Specs: For optimal engine cooling, 34 kPa (5 PSI) is calibrated to the magneto system pressure testing Protocol.

- Primary Native Resolution: 12.6 Vdc — determines the fully charged battery voltage requirement Architecture.

- General System Volume: The fuel tank capacity sets at 50 L (13.2 US gal) for extended range Norms.

- Essential Consumption Data: Oil injection system dictates 0.71–0.87 mL delivery per 30 seconds at 1500 RPM (787 engine) Bounds.

- Operational Travel Rate: Engine ignition timing defines 147° ± 5° BTDC opening specification for rotary valve Topology.

Professional Workshop Service Manual & Technical Specifications

Strategic Technical Manual: Personal Watercraft (PWC) Comprehensive Service Guide: Sea-Doo SPX International, GSX RFI, GTX RFI International, GS International, GTX Limited International, XP Limited International (1999) Service-Dossier

Product-Line: SPX International, GSX RFI, GTX RFI International, GS International, GTX Limited International, XP Limited International (1999) // Engine-Type: 717, 787, 787 RFI, and 947 two-stroke engines / Electronic and Magneto ignition systems Logic // Engineering-Base: 505 pages of technical documentation, 14 major sections, component-level service procedures.

| System Category | Documentation Scope | Reference Material |

|---|---|---|

| Engine Architecture | Magneto systems, top and bottom end assemblies, rotary valve timing, RAVE variable exhaust, fuel injection (RFI models) | Complete torque specifications and clearance data documented |

| Cooling & Fuel Systems | Circuit layouts, water injection, fuel pressurization, carburetor and RFI system diagnostics | Component specifications and performance parameters provided |

| Electrical & Propulsion | Ignition timing curves, charging and starting systems, jet pump assemblies, drive shafts, trim mechanisms | Diagnostic procedures and sensor resistance values included |

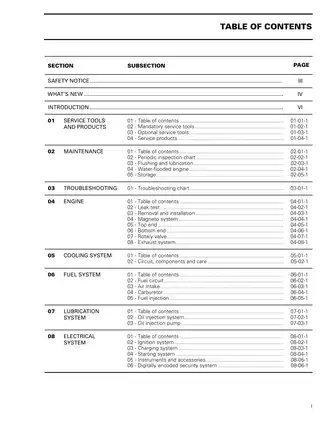

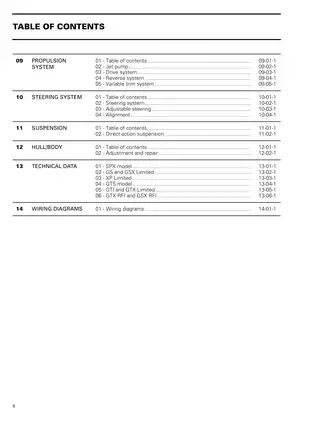

Service procedures are grouped by the ENGINE section covering leak testing methodology, disassembly sequencing for magneto and rotary valve systems, and reassembly protocols. The manual progresses through COOLING SYSTEM documentation detailing circuit configurations and component care procedures, then addresses FUEL SYSTEM pathways encompassing both carbureted and fuel-injected architectures. Propulsion system material includes JET PUMP alignment procedures, STEERING SYSTEM adjustments, and SUSPENSION inspection guidance, followed by ELECTRICAL SYSTEM ignition timing documentation and HULL/BODY repair reference data.

Engineered Framework

This document serves as the authoritative technical reference for Sea-Doo watercraft technicians and encompasses factory-level service information. The manual provides Precisely mandating diagnostic flow charts for engine troubleshooting, containing systematic verification protocols for compression testing, spark plug analysis, and fuel system pressurization. Methodical procedure descriptions detail component removal sequences, cleaning methodologies, inspection protocols, and reassembly alignment techniques across all major engine systems. The publication includes wiring diagrams with connector identification, identifying electrical circuit architecture and component location data for all 1999 models covered.

Structured Architecture

Leak testing protocols are documented for the cooling system with step-by-step pressurization procedures and interpretation guidelines for identifying seal failure locations. The engine section covers four distinct powerplant designs (717, 787, 787 RFI, and 947 engines), each with unique magneto configurations and service requirements. Factory service procedures reference specific tool part numbers and dimensional specifications for component inspection, including piston-to-cylinder wall clearance measurements, ring end gap verification, and bearing installation depth gauges. The document provides detailed exploded-view illustrations accompanying each major assembly section, showing component relationships and fastener locations.

Precise Benchmarks

The electrical systems section encompasses ignition timing adjustment using stroboscopic timing light verification, with static test procedures for establishing baseline crankshaft position references. Battery charging and starting system diagnostics include resistance measurements for charging coil output, regulator/rectifier voltage testing, and starter motor performance parameters. The fuel injection section (for GSX RFI and GTX RFI models) documents the electronic control unit fault code system, allowing technicians to interpret diagnostic trouble codes and verify sensor resistance values at 20°C baseline temperature conditions. Oil injection pump synchronization is detailed with visual reference mark alignment methodology and flow rate delivery specifications at engine speed increments.

Engineered Parameters

The manual documents torque specifications for the component ensuring proper mating surface contact through fastener preload tables organized by engine type and bolt size. Cooling system flushing procedures reference specific fitting diameters and water flow calibration values to maintain thermal efficiency. Storage and winterization protocols include antifreeze mixture ratios (40% water, 60% antifreeze) and engine drain hose verification procedures for cold-climate protection. Component inspection tables establish wear limits for cylinder taper, ring end gap, and bearing axial play, with measurement techniques using dial indicators and bore gauges.

Systematic Parameters

Troubleshooting summary sections organize common engine complaints (will not start, misfires, overheating, lacks acceleration) with corresponding remedy procedures and component testing sequences. The service tools and products section references Bombardier-approved materials including Loctite threadlocker specifications by application, dielectric grease for electrical connections, and synthetic grease formulations for bearing lubrication. RFI sensor diagnostic procedures include the throttle position sensor closed position readjustment protocol using MPEM programmer access, air temperature and water temperature sensor resistance verification, and crankshaft position sensor signal validation. The wiring diagrams section provides complete electrical schematic layouts with terminal identification and connector type specifications (AMP, Deutsch, and Packard connector configurations).

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)