2001-2006 Yamaha Raptor 660 ATV Service Manual

Complete service and repair reference for YFM660R models. Covers engine, transmission, chassis, electrical systems with factory specifications and step-by-step procedures. 331 pages of professional-grade technical documentation.

Manual Preview

Sample pages from the 2001-2006 Yamaha Raptor 660 ATV Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha Raptor 660 (5LP1, 5LP3) — 2001–2006 Diagnostic Archive | Raptor Series Repository.

- Certified Holding Capacity: Engine oil capacity controls 2.3 L (2.02 lmp qt, 2.43 US qt) total system volume Architecture.

- Designated Measurement Bounds: For liquid-cooled operation, radiator capacity is measured at 1.3 L (1.14 lmp qt, 1.37 US qt) Norms.

- Defined Circuit Specs: Fuel tank capacity reaches 12 L (2.64 lmp gal, 3.17 US gal) with reserve amount Bounds.

- Key RPM Specs: Standard compression pressure delivers 1,250 kPa (12.5 kg/cm² at sea level, 181 psi) Topology.

- Primary Installation Footprint: The cylinder displacement indicates 660 cm³ (100.0 × 84.0 mm bore × stroke, 40.4 cu in) Matrix.

- Baseline Charge Quantity: Battery capacity is specified as 12 V 12 Ah (YTX14-BS sealed type lead-acid) Standards.

Professional Workshop Service Manual & Technical Specifications

Enhanced Technical Hydraulic Manual: ATV Pro-Grade ATV Diagnostics: Yamaha Raptor 660 (2001-2006) Field-Reference

Serial-Range: Raptor 660 (2001-2006) // Diagnostic-Area: Engine, Transmission, and Suspension Logic // Serial-Range: Comprehensive service documentation for single-cylinder liquid-cooled ATV platform.

| Documentation Element | Scope | Coverage Details |

|---|---|---|

| Engine Systems | Complete specifications provided | Cylinder head, camshaft, valve clearance, compression data |

| Transmission Architecture | Full component listing | Gear ratios, shift fork assembly, transmission troubleshooting |

| Cooling and Electrical | System categories documented | Radiator, thermostat, battery maintenance procedures |

The repository is divided into nine major chapters addressing the Yamaha YFM660 platform, encompassing General Information and vehicle identification procedures, examining Specifications with detailed measurements and torque documentation, establishing Periodic Checks and Adjustments covering maintenance intervals, detailing Chassis components including suspension and brake systems, exploring Engine architecture with cylinder and crankshaft assembly, defining Cooling System water pump and radiator operation, analyzing Carburetion fuel delivery with jet sizing, investigating Electrical systems spanning ignition through charging circuits, and synthesizing Troubleshooting frameworks for fault diagnosis across all operating systems.

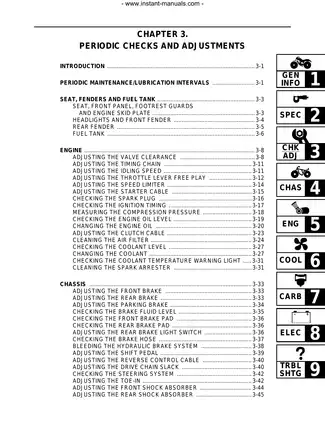

Strategic Threshold

Service procedures are documented for valve clearance alignment, timing chain tensioning, idling speed regulation, throttle lever free play positioning, spark plug inspection and gap verification, ignition timing verification using stationary pointer alignment, and engine oil level assessment. The manual includes exploded diagrams with numbered disassembly sequences, job instruction charts specifying component order, and symbol marking systems to identify lubrication requirements and torque specifications.

Comprehensive Parameters

Calibration requirements are specified for brake system bleeding, rear brake pedal height positioning, parking brake cable end length adjustment, drive chain slack measurement and tensioning, front shock absorber spring preload setting, and rear shock absorber compression/rebound damping force configuration. Electrical system documentation covers battery voltage measurement protocols, fuse continuity checking procedures, charging system voltage testing at 5,000 rpm, ignition spark gap minimum specification of 6.0 mm, and switch continuity verification methodologies using pocket tester instrumentation.

Technical Protocol

Electrical system documentation covers battery charging methods for sealed MF-type batteries including variable voltage and constant voltage charger procedures, charging time determination based on open-circuit voltage measurement, and terminal cleaning protocols. The manual documents torque specifications for all fasteners from M6 through M20 bolt sizes, with specifications ranging from 5.1 ft-lb (7 Nm) for small fasteners to 110 ft-lb (150 Nm) for critical assemblies like AC magneto rotor installation.

Engineered Interface

Disassembly instructions are documented for front and rear brake calipers including piston removal using compressed air, caliper piston seal and dust seal replacement marking new component requirements, and brake hose installation procedures with union bolt torque specifications. Steering system documentation addresses handlebar removal sequence, steering stem bearing retainer installation with damper rod holder tooling, tie-rod end checking for free play detection, and ball joint replacement procedures using specialized remover/installer attachment sets.

Operational Methodology

Suspension service documentation covers shock absorber removal procedures distinguishing front coil spring/oil damper configurations from rear coil spring/gas-oil damper assemblies, relay arm and connecting arm bushing installation with lithium soap base grease application, and swingarm pivot shaft bearing installation with specified depth measurements. The manual documents torque specifications for the Raptor 660 to ensure proper seal compression uniformity, with detailed tightening sequences for cylinder head installation using crisscross progressive stages and crankcase assembly using stage-wise bolt torquing patterns.

Fuel system documentation includes carburetor disassembly procedures identifying jet needle holder springs, piston valve inspection for scratches, float chamber drain screw access, and needle valve seat cleaning. Air intake system procedures address air filter element cleaning in kerosene solvent with engine oil reapplication, and crankcase breather hose inspection for cracks or deterioration damage.

Transmission documentation specifies shift drum segment installation with notch alignment to shift cam pins, shift fork guide bar examination for bends, transmission gear tooth condition assessment for pitting wear, and deflection measurement methodology using centering devices with dial gauge instrumentation.

FAQ

Customer Reviews

Read what our customers say about this Yamaha ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)