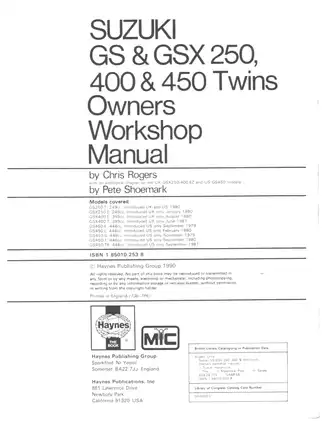

1979-1985 Suzuki GS/GSX 250, 400 & 450 Twins Repair Manual

Complete service and maintenance procedures for GS250T, GSX250E, GSX400E/T, and GS450 models. Covers engine, clutch, gearbox, fuel system, ignition, and chassis repairs with detailed specifications and torque settings.

Manual Preview

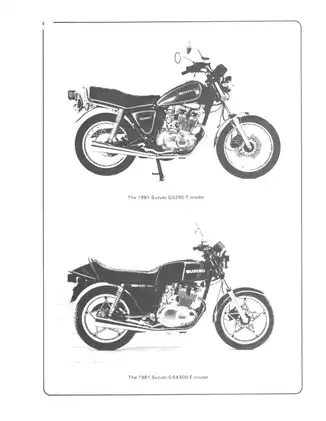

Sample pages from the 1979-1985 Suzuki GS/GSX 250, 400 & 450 Twins Repair Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki GS/GSX 250, 400 & 450 Twins — 1979–1985 Advanced Systematic Documentation | Suzuki GS Series Archive.

- Verified Generation Capacity: 249 cc to 448 cc displacement is measured at the twin-cylinder air-cooled engine architecture Bounds.

- Engineered Working Temperature: For optimal performance, 0.08–0.13 mm valve clearance (cold) represents the intake and exhaust valve tolerance Framework.

- Prescribed Operational Speed: Maximum engine speed is established at 3500 + 100 rpm for ignition timing advance procedures Topology.

- Nominal Addressable Resolution: The compression ratio is set to 10.5:1 (250 models) and 10.0:1 (400 models) for combustion chamber pressure Matrix.

- Defined Reservoir Specs: Tank volume produces 11–14.5 L (2.4–3.8 Imp/US gal) total fuel capacity requirements Standards.

- General Amperage Specs: Sparking plug gap is configured at 0.6–0.7 mm (0.024–0.028 in) for electrical ignition system operation Protocol.

Professional Workshop Service Manual & Technical Specifications

Definitive Service Diagnostic Manual: Motorcycle 1979-1985 Suzuki GS/GSX 250, 400 & 450 Twins - Maintenance, Diagnostics & Repair Manual Hydraulic-Guide

System-Identifier: GS250T, GSX250E, GSX250EZ, GSX400E, GSX400T, GS450E, GS450L, GS450S, GS450T, GS450TX // Design-Core: Twin-cylinder four-stroke air-cooled engine / Double overhead camshaft propulsion system Logic // System-Identifier: DOHC parallel twin 249-448cc capacity with constant mesh six-speed transmission.

| Performance-Element | Value | Calibration-Standards |

|---|---|---|

| Engine Configuration | Twin-cylinder DOHC four-stroke | Documented across all covered models |

| Transmission | Six-speed constant mesh gearbox | Complete specifications provided |

| Ignition System | Transistorised CDI with automatic timing unit | Comprehensive timing data included |

| Fuel Delivery | Dual Mikuni CV carburettors | Float chamber fuel level reference documented |

| Lubrication Architecture | Forced pressure wet sump system | Oil pressure and capacity specifications included |

Technical content addresses engine and transmission systems, fuel system components, ignition timing procedures, and cooling system maintenance. The manual encompasses clutch assembly operations, gearbox component examination, final drive chain adjustment, brake system servicing, electrical system configuration, and steering head bearing maintenance, with procedures covering spark plug maintenance, ignition synchronisation, carburettor adjustment, and oil filter renewal throughout the document.

Strategic Sequences

Methodically requiring attention to component specifications, the document includes torque specifications for engine mounting bolts, cylinder head fasteners, connecting rod caps, camshaft journal retaining bolts, and primary drive gear pinion nuts to ensure proper fastener fatigue prevention. The manual documents valve clearance reference data with cold-engine adjustment procedures, cam chain tensioner settings, and rocker arm configuration details for optimal valve train operation.

Precise Logic-Path

Technical notes are provided for counterbalance shaft examination, including bearing shell renewal criteria and shock absorber spring service limits across 250 and 400cc models. The gearbox section covers mainshaft and layshaft assembly sequences, selector fork clearance measurement, gear pinion groove width specifications, and bearing location half clip positioning procedures. Complete specifications are documented for crankshaft journal oil clearance, connecting rod big-end width tolerances, and thrust bearing thickness limits.

Modular Nexus

Quality checks are addressed for cylinder block bore wear measurement, piston ring groove clearance verification, piston-to-bore clearance determination, and cylinder head distortion limits using straight-edge and feeler gauge techniques. The document outlines camshaft bearing journal clearance assessment using plastigage strip methodology, cam lobe height verification, and camshaft runout measurement procedures with diagnostic limits for determining component renewal requirements.

Systematic Sequences

The troubleshooting chapter addresses engine seizure symptoms, excessive mechanical noise diagnosis, lubrication failure indicators, and performance degradation pattern recognition. Cooling system maintenance is addressed in sections covering air filter element cleaning intervals, element inspection for tears or hardening, and fuel system component examination including fuel tap diaphragm operation, carburettor float chamber gasket condition assessment, and pilot jet sizing reference data across multiple model variants and market regions.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)