1985-1986 Honda ATC 350X Service Manual

Complete factory service documentation for the Honda ATC 350X featuring engine specifications, clutch assembly, transmission details, hydraulic brake procedures, and detailed suspension maintenance. Full technical reference with torque values, diagnostic flowcharts, and parts identification.

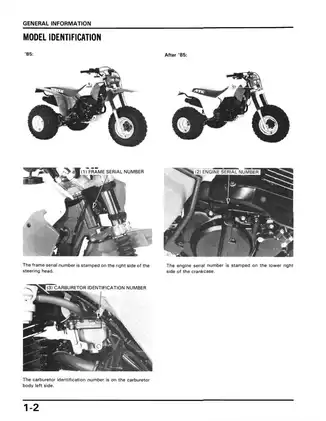

Manual Preview

Sample pages from the 1985-1986 Honda ATC 350X Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda ATC 350X — 1985–1986 Licensed Strategic Sourcebook | ATC 350X Repository.

- Calibrated Engine Displacement: 350.4 cc (21.38 cu in) is specified as the total cylinder volume capacity Architecture.

- Documented Compression Ratio: For optimal combustion efficiency, 8.5:1 defines the standard engine compression characteristic Framework.

- Authorized Maximum Horsepower: 27 PS/7,000 rpm — represents the peak engine power output Baseline.

- Core Fuel Tank Capacity: The primary fuel tank requires 9.7 liters (2.56 US gal) for standard operating parameters Threshold.

- Rated Engine Oil Capacity: Motor oil volume reaches 2.3 liters (2.43 US qt) after complete disassembly requirements.

- Principal Valve Clearance: Intake and exhaust valve gaps are set to 0.08 mm (0.003 in) cold lash standards Guidelines.

Professional Workshop Service Manual & Technical Specifications

Industrial Reference Manual: Three-Wheeler Comprehensive Repair Manual: Honda ATC 350X (1985-1986) Transmission-Guide

Calibration-Scope: ATC 350X (1985-1986) // Performance-Values: Three-Wheeler Operation / Drivetrain Logic // Model-Designation: Single-cylinder air-cooled four-stroke engine documentation.

| Documentation Category | Content Scope | Reference Status |

|---|---|---|

| Engine and Transmission Systems | Specifications, torque values, service procedures | Complete specifications provided |

| Brake and Suspension Components | Hydraulic systems, front and rear assemblies | Documented across multiple chapters |

| Electrical and Fuel Systems | Ignition timing, carburetor adjustments, wiring | See Sections 4 and 16 |

Appropriately mandating comprehensive technical coverage, the documentation encompasses Engine Removal and Installation procedures, alongside Lubrication guidance and Maintenance schedules that address seasonal service intervals. The manual transitions through Fuel System configuration, detailing Carburetor operation and Float Chamber assembly, then progresses to Cylinder Head and Valve specifications, incorporating Camshaft installation methodologies. Following these core engine topics, the guide addresses Clutch and Oil Pump systems, Alternator functionality, and complete Gearshift Linkage assembly instructions. The documentation further provides Crankcase Separation techniques, Transmission disassembly protocols, and Crankshaft inspection parameters, establishing a complete Drivetrain reference foundation.

Core Methodology

The documentation includes service specifications for all major assemblies, with particular emphasis on suspension components and hydraulic brake systems. Front Wheel maintenance encompasses bearing replacement procedures and tire repair techniques, while Steering Stem adjustment data ensures proper handlebar alignment. Specifications for brake fluid replacement and system bleeding are documented, along with caliper disassembly requirements for both front and rear brake applications.

Strategic Benchmarks

Torque specifications are documented throughout this manual to ensure proper fastener integrity across all mechanical assemblies. Valve clearance reference data is included for intake and exhaust valve adjustment, supporting correct engine combustion timing. The documentation provides electrical system schematics, including Alternator output specifications and CDI unit testing procedures, facilitating comprehensive ignition system diagnosis and service validation.

Diagnostic Framework

Troubleshooting sections reference diagnostic methodologies for engine starting issues, performance degradation at varying speeds, and suspension handling characteristics. The manual addresses both carburetor and fuel system diagnostics, incorporating float level specifications and fuel strainer cleaning procedures. Comprehensive brake system troubleshooting encompasses hydraulic fluid condition assessment, pad wear monitoring, and caliper piston inspection protocols.

Operational Sequences

Rear suspension service includes shock absorber disassembly and nitrogen pressure specifications, documented for preload adjustment across rider weight variations. Rear Wheel and Axle maintenance procedures incorporate bearing replacement techniques and sprocket installation requirements. The documentation provides cable and harness routing diagrams, ensuring proper electrical system organization and preventing operational interference with moving components.

Integrated Nexus

The manual documents torque specifications for the primary drive gear to ensure proper engagement security and transmission reliability. Specifications encompassing cylinder compression ranges, ignition timing parameters, and fuel system pressures establish baseline metrics for performance validation. Comprehensive service intervals, tool requirements, and special equipment specifications are provided throughout, supporting authorized technician-level service operations.

FAQ

Customer Reviews

Read what our customers say about this Honda Three-Wheeler manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)