1970-1985 Honda ATC 70/90/110/125 Service Manual

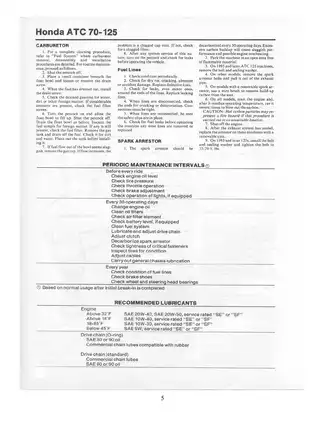

Diagnostic procedures and component service for all ATC models with valve clearance, torque specifications, and complete engine rebuild guidance. Covers carburetor adjustment, spark plug gaps, and chassis maintenance procedures.

Manual Preview

Sample pages from the 1970-1985 Honda ATC 70/90/110/125 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda ATC 70, ATC 90, ATC 110, ATC 125 — 1970–1985 Applied Digital Reference | ATC Series Set.

- Reference Electrical Specs: 175 ± 22 psi is standardized to engine compression pressure measurement at wide-open throttle operation Sequences.

- Integral Amperage Specs: For optimal valve operation, 0.05 mm (0.002 in.) defines the intake and exhaust clearance Baseline.

- General Heat Dissipation: 0.3–0.4 mm (0.012–0.016 in.) — achieves the breaker point gap specification Requirement.

- Certified Footprint Data: The spark plug requires 0.6–0.7 mm (0.024–0.028 in.) electrode spacing for ignition Threshold.

- Factory Securement Values: Float level setting reaches 20.0 mm (0.78 in.) on carburetors produced between 1970 and 1977 Mapping.

- Established Dimensional Tolerance: 3.0 psi — sets the tire pressure Configuration for the ATC 70 model years 1970–1981.

Professional Workshop Service Manual & Technical Specifications

Applied Shop Service Manual: Three-Wheeler Comprehensive Maintenance: Honda ATC 70, ATC 90, ATC 110 and ATC 125 Service Manual (1970-1985) Resource-Library

Model-Portfolio: ATC 70 (1970-1981), ATC 70 (1981-On), ATC 90 (1970-1977), ATC 90 (1978-On), ATC 110 (1979-1981), ATC 110 (1982-On), ATC 125 (1985 and Earlier) // Serial-Range: Frame and engine serial number locations documented for all model generations // Technical-Domain: Complete specifications, torque values, and diagnostic procedures across powertrain and chassis systems.

| Component | System-Path | Validation-Data |

|---|---|---|

| Engine Assembly | Crankshaft, connecting rod, piston systems | Service limits and inspection techniques included |

| Transmission | Shift mechanism, gear clusters, clutch function | Gear backlash and fork clearance documented |

| Fuel Management | Carburetor, petcock, filter maintenance | Float level settings and jet configuration reference |

| Ignition Circuit | Breaker points, magneto, CDI systems | Contact surface conditions and coil resistance specifications |

| Brake Systems | Front drum, rear drum, lever adjustments | Lining wear limits and drum diameter service limits |

Service sections detail engine and transmission removal procedures, address chassis lubrication intervals and front-end bearing adjustment, cover fuel system maintenance routines, examine electrical system troubleshooting methods, and encompass brake component inspection standards.

Structured Standard

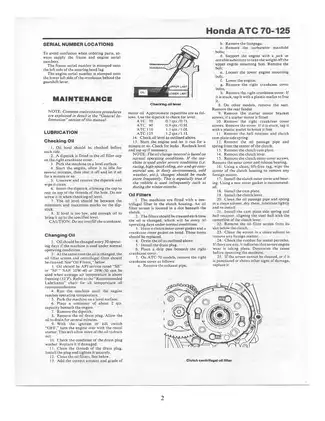

Correctly calling for comprehensive technical content, the documentation encompasses disassembly and reassembly sequences for all major engine components including the cylinder head, piston rings, and crankshaft assemblies. Wear limits are specified for cylinder ID, piston clearance, and connecting rod radial play to support field diagnostics. The manual contains detailed specifications for compression testing procedures, cam chain tensioner operation across different model years, and valve clearance settings that vary by displacement class.

Systematic Benchmarks

System operation descriptions cover fuel delivery through tank-mounted and carburetor-mounted petcock configurations, with procedures for checking float level positioning and main jet sizing across model generations. The documentation addresses ignition timing marks and rotor alignment procedures, explaining the "F" mark synchronization method for both mechanical and electronic systems. Electrical test procedures are documented for ignition coil primary and secondary winding resistance, condenser capacitance verification on breaker point models, and CDI pulse generator air gap adjustment.

Technical Logic-Path

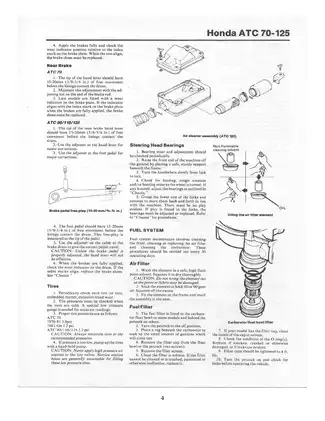

The documentation addresses clutch operation standards including lever free-play verification and adjuster cam plate positioning. Assembly instructions are detailed for drive chain adjustment mechanisms, showing chain free-play measurement points and tensioner nut positioning on different model configurations. Hydraulic schematics are included for brake system layouts, depicting front and rear drum arrangement with lever and rod interconnections. Specifications document oil pump body clearance, rotor tip clearance, and end-play verification methods essential for internal engine diagnostics.

Structured Nexus

Component inspection procedures reference bearing radial and axial play limits, sprocket tooth wear patterns, and crankcase half mating surface warpage tolerances. The manual provides steering stem bearing adjustment instructions using ring nut positioning and ball count specifications, along with front fork tube bolt torque sequencing. Comprehensive chassis specifications table includes wheel bearing pressed-fit installation methods and dust seal positioning for front and rear axle assemblies. The document includes oil change capacity specifications by displacement (0.7 to 1.2 quarts depending on model) and recommends specific lubricant grades for engine, transmission, and chassis applications.

Integrated Standard

Carburetor disassembly sequences reference pilot jet removal, needle jet holder extraction, and float bowl gasket replacement across different carb configurations used in the four-model lineup. The manual documents torque specifications for critical fasteners including cylinder head stud nuts (6.5-8.7 ft lbs on ATC 70, 14-16 ft lbs on ATC 90-125), camshaft sprocket bolts (3.6-6.5 ft lbs ATC 70, 6-9 ft lbs on larger models), and crankcase screws. Reference sections identify serial number locations on frame and crankcase, clarify model coverage dates and engine displacement specifications, and detail recommended maintenance intervals based on operating days and seasonal conditions.

The manual documents torque specifications for the clutch hub nut to ensure proper assembly stress control across all four model variants, with differentiated values reflecting varying displacement requirements between 70cc and 125cc configurations.

FAQ

Customer Reviews

Read what our customers say about this Honda Three-Wheeler manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)