1973-1981 Honda ATC 70, 90, 110, 185S, 200 Workshop Manual

Complete factory workshop procedures for all Honda All-Terrain Cycle models. Covers engine, transmission, fuel systems, ignition, brakes, wheels, and electrical components. Haynes technical reference for 70cc, 90cc, 110cc, 185cc and 200cc three-wheelers.

Manual Preview

Sample pages from the 1973-1981 Honda ATC 70, 90, 110, 185S, 200 Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda ATC 70, 90, 110, 185S & 200 — 1973-1981 Authoritative Technical Vault | ATC Series Repository.

- Calibrated Displacement Data: 72 cc (4.4 cu in) on ATC 70 is specified as the engine cylinder volume Mapping.

- Measured Power Output: For optimal performance, 13.0 BHP at 7000 rpm represents the maximum rated horsepower Configuration.

- Reference Torque Specifications: Cylinder head nuts require 0.9–1.2 kgf m (6.5–8.7 Ibf ft) — is calibrated to the fastening requirement Benchmarks.

- Fundamental Compression Ratio: The engine achieves 9.5:1 on ATC 90 models supports efficient combustion chamber pressure Range.

- Specific Oil Capacity: Tank volume reaches 1.0 lit (2.11/1.76 US/Imp pint) provides the lubrication reservoir Sequences.

- Core Valve Clearance: Inlet and exhaust valves are rated at 0.05 mm (0.002 in) on ATC 70 and 90 models Baseline.

Professional Workshop Service Manual & Technical Specifications

In-Depth Parts Manual: Honda ATC 70, 90 & 110, 185S, 200 Three-Wheeler Troubleshooting-Index

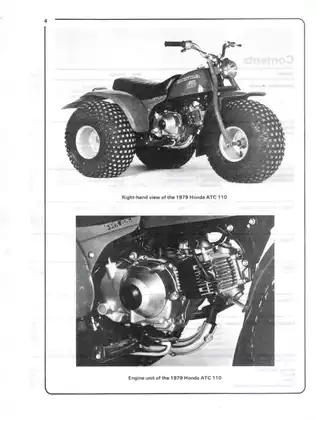

Series-Validation: Honda ATC 70 (1973-1974), ATC 90 (1974-1981), ATC 110 (1979-1981), ATC 185S (1979-1981), ATC 200 (1979-1981) // Assembly-Group: Five-model series / Off-road vehicle propulsion and drivetrain Logic // Series-Validation: 170-page comprehensive service reference, factory-level procedures, metric specifications.

| Documentation Aspect | Coverage | Reference |

|---|---|---|

| Engine Systems | Single-cylinder four-stroke assembly, clutch mechanics, gearbox internals | Chapters 1, 7 |

| Fuel and Ignition | Carburetor configuration, petrol delivery, spark generation | Chapters 2, 3 |

| Chassis and Suspension | Rigid fork construction, frame spine design, wheel bearings | Chapters 4, 5 |

Coverage is segmented into fundamental examination of engine construction and transmission arrangements, incorporates fuel system pathways and carburetor function, extends through ignition timing documentation and contact breaker assembly procedures, encompasses frame geometry and steering head bearing maintenance, and concludes with brake shoe examination and final drive chain tensioning protocols.

Modular Parameters

Thoroughly requiring systematic disassembly sequences for complete top-end rebuilding, the document furnishes crankcase separation methodology alongside connecting rod and bearing component positioning. Service procedures are documented for rocker arm alignment, valve clearance verification, and camshaft chain tensioner adjustment. The manual provides detailed photographic sequences for engine removal from frame, fuel tank detachment protocols, and carburettor cleaning with needle jet examination.

Engineered Nexus

Component locations are identified for clutch operating mechanisms, oil pump positioning, and gearchange spindle routing through frame tunnels. Examination procedures address centrifugal clutch plate wear assessment, friction lining thickness measurement, and automatic advance unit spring tension evaluation. Specifications are documented for crankshaft runout limits, main bearing clearances, and big-end connecting rod side play tolerances.

Comprehensive Standard

Calibration requirements are specified for ignition timing mark alignment using rotor positioning, contact breaker point gap verification between 0.3–0.4 mm, and valve clearance settings between 0.05–0.07 mm depending on model designation. The manual references spark plug electrode gap specifications, throttle cable free-play adjustment measurements, and carburetor float chamber fuel level setting at 20 mm height.

Operational Interface

Electrical system documentation covers generator output verification, ignition coil primary and secondary winding resistance measurement, and headlamp beam height adjustment via mounting bracket tilting. Wiring schematic pages illustrate complete circuit paths for lighting systems on ATC 90 and 110 models, showing snap connector locations and earth ground points throughout the frame.

Precise Threshold

Suspension service documentation covers rigid tubular steel fork inspection for bending or damage assessment, steering head bearing race examination for pitting or indentation wear, and front wheel hub bearing removal using mandrel drift techniques. The manual documents torque specifications for critical fasteners including cylinder head nut values (0.9–1.2 kgf·m), clutch center nut tightening to 3.8–4.5 kgf·m, and final drive chain master link retention procedures.

This document references torque specifications for the cylinder head nuts to ensure proper sealing and structural integrity of the aluminum alloy casting.

FAQ

Customer Reviews

Read what our customers say about this Honda Three-Wheeler manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)