Komatsu PC95-1 Excavator Shop Manual

Comprehensive service and repair documentation for the Komatsu PC95-1 Excavator. Covers structure, function, testing, adjustments, disassembly, and assembly procedures.

Manual Preview

Sample pages from the Komatsu PC95-1 Excavator Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Komatsu PC95-1 Excavator Shop Manual: Komatsu PC95-1 (WEBMPC9500) - Comprehensive Maintenance & Repair Manual

Technical Reference | Set Archive.

- System Alignment Specs: 165 mm is the specified measurement for the track frame alignment Baseline.

- Wattage Specs: For engine power, 85°C indicates the maximum operating temperature Requirement.

- Operating Temps: The engine oil requires 10W oil for proper operation Threshold.

- Angular Speed: The engine speed is set at 2160 rpm for normal operation Logic.

- Optical Resolution: Min. 27 mm defines the travel motor speed Parameters.

- Play Limits: 200 mm is the maximum permissible deviation for travel.

Professional Workshop Service Manual & Technical Specifications

Komatsu PC95-1 Excavator Shop Manual: Komatsu PC95-1 (WEBMPC9500) - Comprehensive Maintenance & Repair Manual

Engine-Type: PC95-1 // Maintenance-Category: Excavator / Hydraulic Logic // Performance-Values: 58.4 bar.

| Metric | Technical-Path | Calibration-Spec |

|---|---|---|

| Engine Speed | High idling | 2160±50 rpm |

| Oil Temperature | Max. 85°C | 85°C |

| Blow-by Pressure | At high idling speed | 60 l/min |

| Fan-belt Tension | Slack with 4.5 kg force | 10 mm |

| Arm Control Valve Pressure | 9±0.5 kg | 9±0.5 kg |

| Boom Swing Pressure | 9±0.5 kg | 9±0.5 kg |

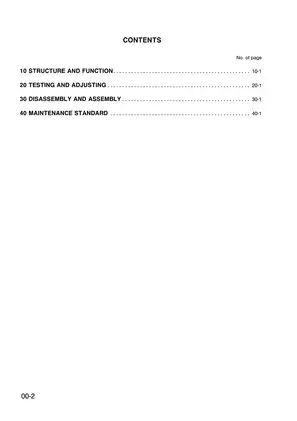

The documentation provides guidance on structure and function, testing and adjusting, disassembly and assembly, and troubleshooting. Key systems covered include the P.T.O., power train, final drive, track frame, swing circle, and swing machinery.

Maintenance guidelines are included for engine, hydraulic, and pneumatic systems.

OEM guidelines are included for the electrical system and troubleshooting procedures.

Transmission service information covers hydraulic pump and gear-pump assemblies.

HVAC system procedures are included for the cabin and heating fan.

Torque specifications are documented for critical components like nuts, bolts, and fittings. This manual documents torque specifications for component alignment retention to ensure proper assembly.

FAQ

Customer Reviews

Read what our customers say about this Komatsu Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)