Komatsu 6D125 Series Diesel Engine Shop Manual

Technical reference for the 1998 Komatsu 6D125 Series diesel engines, including S6D125 and SA6D125 models. Details structure, function, and maintenance. PN 00-1

Manual Preview

Sample pages from the Komatsu 6D125 Series Diesel Engine Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Technical Procedure Factory Manual: Diesel Engine Official-Issue Komatsu 6D125 series manual: S6D125, SA6D125 Parts-Reference Komatsu 125 Series (00-1) - Diesel Engine Manual. Engineering Manual Archive Package.

- Measured Power Framework: For optimal output, 146/1800 establishes the maximum engine performance Range.

- Established Operating Temps: The standard operating temperature range is 40 to 45°C for optimal performance Configuration.

- Factory Cycle Rate: The engine operates at a low idling speed between 650 - 700 rpm for consistent operation Benchmarks.

- Approved Package Size: The engine's dry weight is 970 kg, suitable for various heavy-duty applications Baseline.

- Reference Current Rating: The fuel pump type is specified as Bosch PE-NB, ensuring reliable performance Parameters.

- Critical Moment Values: The maximum torque is 68/1,300 kgm/rpm, indicating robust power delivery Sequences.

Professional Workshop Service Manual & Technical Specifications

Technical Procedure Factory Manual: Diesel Engine Official-Issue Komatsu 6D125 series manual: S6D125, SA6D125 Parts-Reference

Komatsu 6D125 Series (00-1) // Operational-Framework: Diesel Engine / Diesel Engine Logic // Operational-Framework: Technical-Documentation.

TOP

| Component | System-Path | Context |

|---|---|---|

| Engine model | 6D125-1 | Applicable machine: D50A-17, D50P-17, D50F-17, D53A-17 |

| Bore x Stroke (mm) | 6 – 125 x 150 | All models listed above |

| Total piston displacement (cc) | 11,040 | All models listed above |

| Firing order | 1 – 5 – 3 – 6 – 2 – 4 | All models listed above |

| Flywheel horsepower (HP/rpm) | 120/1,750 to 165/1,800 | Varies by model, see specs. |

| Maximum torque (kgm/rpm) | 64.8/1,300 to 81.5/1,100 | Varies by model, see specs. |

| Dry weight (kg) | 970 to 1,275 | Varies by model, see specs. |

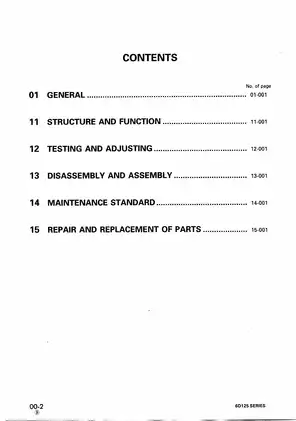

Introduction: Service procedures are grouped by chapter for ease of understanding. This manual contains the necessary technical information for operations performed in a service shop, giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgments. Completely requiring...

Assembly instructions are detailed for the engine's main circulation part, including the oil pump and relief valve.

Detailed diagrams and explanations cover the engine's fuel system, including the fuel tank, pump, filters, and injection nozzles.

Hydraulic schematics are included for the cooling system, showing the radiator, water pump, thermostat, and oil cooler.

Information on the electrical system, including the alternator, starting motor, and air heater, is provided.

Steering component information is provided for the engine stop motor and related circuits.

Maintenance standards and repair procedures for various components are documented.

Torque Statement: This manual documents torque specifications for components to ensure proper flange face sealing.

FAQ

Customer Reviews

Read what our customers say about this Komatsu Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)