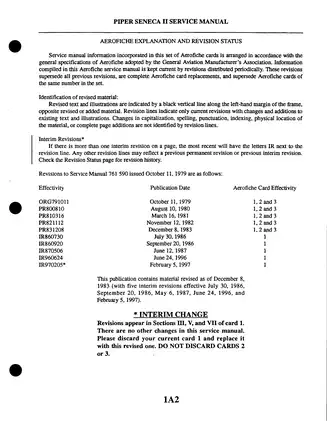

1975-1981 Piper Seneca II PA-34-200T Service Manual

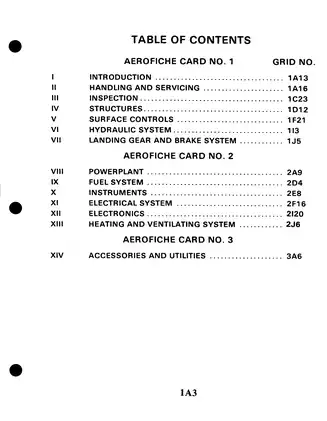

Comprehensive service and maintenance data for the Piper Seneca II PA-34-200T, covering structures, surface controls, hydraulic systems, and more. Part number 761 590.

Manual Preview

Sample pages from the 1975-1981 Piper Seneca II PA-34-200T Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Piper Seneca II PA-34-200T Service Manual - Comprehensive Guide Documentation-Framework

Piper Seneca II PA-34-200T (761 590) | Aircraft / Aircraft Logic.

- Authorized Production Rate: 200 Rated Horsepower sets the standard engine output Metrics.

- Critical Physical Specs: For overall dimensions, 28 ft. 7.5 in. defines the fuselage length Framework.

- Operational Output Quality: The hydraulic system operates at 2000-2500 psi -- indicates the system's operational pressure Threshold.

- Fundamental Fill Levels: The oil sump capacity requires 8 U.S. quarts for optimal lubrication Logic.

- Specific Assembly Gap: The stabilator free play requires .125 inches maximum for proper control surface alignment Parameters.

- Core Print Rate: The landing gear is fully retractable and is operated hydraulically Framework.

Professional Workshop Service Manual & Technical Specifications

Piper Seneca II PA-34-200T Service Manual: Aircraft Piper Seneca II PA-34-200T Service Manual - Comprehensive Guide Documentation-Framework

Product-Line: Piper Seneca II PA-34-200T // Asset-ID: 761 590 / Aircraft // Product-Line: Service Manual

Table: TOP

| Specification | Technical-Path | Architecture |

|---|---|---|

| Engine Oil Sump Capacity | 8 U.S. quarts | Standard Lubrication |

| Hydraulic System Pressure | 2000-2500 psi | Gear Type Unit |

| Fuselage Length | 28 ft. 7.5 in. | Semi-monocoque Structure |

| Stabilator Free Play | .125 inches maximum | Control Surface Alignment |

| Rudder Pedal Travel | 23° each way from neutral | Hydraulic Operation |

| Wing Flap Positions | 10°, 25°, 40° | Interconnecting System |

Repair procedures are structured around systems and components, detailing removal, installation, rigging, and adjustment procedures. Key systems covered include the hydraulic system, surface controls (ailerons, stabilator, rudder, flaps), landing gear, and fuselage/empennage. The manual also references important torque specifications and lists consumable materials. Information for the powerplant is based on manufacturer operator's manuals.

The manual provides procedures for inspecting and servicing various aircraft components and systems. It details the necessary steps for the removal and installation of parts, ensuring proper rigging and adjustment for optimal performance. The documentation covers a wide range of systems, including those related to the aircraft's structure, flight controls, and power plant.

FAQ

Customer Reviews

Read what our customers say about this Piper Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)