1985 Honda Big Red ATC250ES Three-Wheeler Service Manual

Complete Honda ATC250ES service procedures including engine removal, transmission repair, and suspension systems. Factory service specifications and torque values for 246cc 4-stroke overhead camshaft engine.

Manual Preview

Sample pages from the 1985 Honda Big Red ATC250ES Three-Wheeler Service Manual manual

Purchase & Download

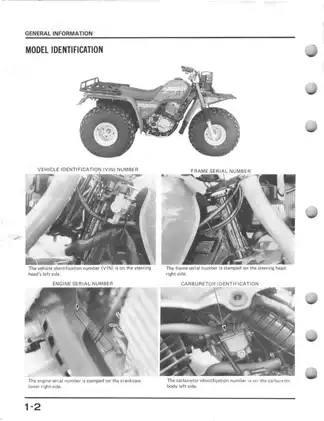

Models Covered & Key Technical Specifications

Honda ATC250ES Big Red — 1985 Automotive Engineering Reference Toolkit | ATC250ES Series Repository.

- Prescribed Fastening Values: 246 cc (15.0 cu in) is measured at the engine cylinder displacement Bounds.

- Documented Threaded Fastener Data: For peak power delivery, 17.8 BHP at 7000 rpm represents the maximum rated horsepower Topology.

- Maximum System Fill: 1.9 kg-m (13.7 lb-ft) at 6000 rpm is established at crankshaft torque Matrix.

- System Power Framework: The fuel tank requires 12 liters (3.2 US gal) for standard fuel capacity Standards.

- Technical Throughput Data: Engine compression ratio produces 9.0:1 operational specification Margin.

- Advanced Output Density: Front fork oil volume is configured at 113±2.5 cc (3.8±0.08 oz) Protocol.

Professional Workshop Service Manual & Technical Specifications

Complete Troubleshooting Workshop Manual: Honda ATC250ES (Big Red) Three-Wheeler Reference Library

System-Coverage: ATC 250ES, Big Red 250 // System-Coverage: Drivetrain and engine systems specifications // Specification-Class: Factory-standard technical documentation, 284 pages, comprehensive component coverage.

| Identifier | System-Path | Framework |

|---|---|---|

| Engine Systems | Fuel delivery, carburetor operation, ignition timing | Factory specifications documented |

| Chassis Configuration | Brake operation, suspension adjustment, steering | Complete procedural reference |

| Drivetrain Assembly | Clutch mechanisms, transmission gearing, final drive | Service intervals and clearance data |

| Electrical Networks | Alternator output, battery charging, starter systems | Wiring diagrams and testing methods |

| Maintenance Protocols | Oil change procedures, filter service, lubrication points | Scheduled intervals and fluid capacities |

Organized into dedicated modules for engine systems, brake control linkage, and final drive assembly, the documentation establishes clutch adjustment procedures, covers suspension components with spring tension specifications, and addresses fuel system operation. The manual structures transmission service by detailing shift fork engagement, countershaft bearing clearances, and piston ring end gaps with precise measurement requirements. Technical notes are provided for carburetor choke mechanisms, examining float level specifications and jet sizing across altitude variants. Quality checks are addressed for valve timing alignment, encompassing intake and exhaust cam lobe height confirmation and rocker arm clearance validation. The troubleshooting chapter addresses hard starts by tracing fuel flow restrictions, spark ignition faults, and compression anomalies through systematic diagnostic sequences.

Diagnostic Architecture

Timing procedures are documented for crankshaft rotation positioning relative to flywheel timing marks, ensuring proper ignition advance at idle and full throttle conditions. The ignition system section details CDI unit functionality, pulse generator signal interpretation, and coil resistance thresholds for primary and secondary winding continuity. Specifications reference the factory-preset ignition advance curve, documenting thirteen degrees BTDC at 1,400 rpm and thirty-one degrees BTDC at 3,500 rpm with acceptable tolerance bands. Brake shoe wear indicators are cross-referenced with brake drum I.D. limits to prevent excessive pad degradation. The manual documents that the centrifugal clutch uses left-hand threaded lock nuts, requiring clockwise removal to prevent fastener stripping during maintenance intervals.

Strategic Benchmarks

Technical notes are provided for output gear case bearing preload measurement, establishing baseline backlash between pinion and ring gears across three axis points with tolerance documentation. The document includes wiring diagrams segmented by model year, depicting alternator charging coil connections, battery polarity routing, and neutral switch logic circuits. Cylinder compression test procedures establish reference pressures of twelve to thirteen kilograms per square centimeter, enabling rapid diagnostic differentiation between valve train faults and piston ring wear. The fuel system section catalogs jet sizes by model variant, distinguishing between standard main jets (number 130) and high-altitude replacements (number 125) with corresponding pilot screw adjustments. Frame and body torque sequences specify diagonal tightening patterns in two to three steps, preventing gasket misalignment and crankcase warpage during engine assembly phases.

Strategic Protocol

The document includes torque specifications for the cylinder head cap nut assembly at thirty-five to forty-five Newton-meters to ensure proper head gasket compression while maintaining thread integrity. The clutch system documentation addresses both semi-automatic centrifugal and manual multi-plate configurations, cataloging disc thickness wear limits at 2.3 millimeters and plate warpage tolerance at 0.20 millimeters. Steering head bearing adjustment procedures employ initial and final torque values, requiring lock-to-lock rotation testing to verify smooth steering feel after adjustment completion. The transmission section details all five forward speeds plus reverse, documenting first gear ratio at 2.407:1 and fifth gear at 0.906:1 with corresponding mainshaft and countershaft bushings' outside diameters. Cable routing diagrams illustrate proper throttle, brake, and reverse lock cable paths to prevent binding during full handlebar rotation through all steering positions.

Comprehensive Protocol

The suspension systems documentation examines both front telescopic fork travel at 115 millimeters and rear swingarm suspension with 110 millimeters of travel, including spring free length specifications and damper rebound spring characteristics. Electrical troubleshooting procedures trace starter motor brush length wear to 5.5 millimeters for Mitsuba units and 8.5 millimeters for ND equivalents, requiring replacement when service limits are exceeded. The final drive section provides ring gear tooth contact pattern analysis using Prussian Blue transfer methods, demonstrating proper face engagement and identifying contact shift directions indicating excessive preload. Brake system procedures address both front cable-operated leading shoe and rear drum configurations with independent cable adjustment protocols using upper and lower adjustment nuts. The manual documents torque specifications for the swingarm pivot bolt at 100 to 130 Newton-meters (left) and 16 to 20 Newton-meters (right) with subsequent retightening after operational cycling to ensure bearing retention.

Precise Framework

The carburetor assembly section catalogs component identification numbers distinguishing 1985 models (OA01A with variant markings) from post-1985 versions (OA07A), enabling correct float chamber gasket and seal ring selection. Oil viscosity recommendations reference SAE 10W-40 classification with temperature-dependent alternatives documented in chart format, guiding seasonal fluid selection across global operating environments. Ignition system documentation establishes C.D.I. unit testing procedures with specific resistance measurements across primary, secondary, and exciter coil pathways, identifying component faults through ohmmeter continuity checks. The document includes detailed cam chain tensioner lifter assembly sequences, contrasting 1985 mechanical adjustment mechanisms with post-1986 spring-loaded automatic retention systems. Battery specifications establish 12-volt, 10-ampere-hour capacity with recommended charging currents of 1.0 ampere standard and 5.0 ampere maximum, allocating five hours for standard charging and one hour for emergency rapid charging protocols.

The manual documents torque specifications for the output gear bearing lock nuts at ninety to 110 Newton-meters to ensure proper final drive assembly preload and fastener fatigue prevention.

FAQ

Customer Reviews

Read what our customers say about this Honda Three-Wheeler manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews