Kohler CH18-750 Command Horizontal Engine Service Manual

30 HP horizontal crankshaft with service procedures for fuel systems, ignition, electrical components, and complete engine disassembly/reassembly. Factory documentation PN: CH18-750.

Manual Preview

Sample pages from the Kohler CH18-750 Command Horizontal Engine Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kohler CH18-750 Command Horizontal Engine — Service Manual Reference Applied Reference Repository | CH750 Series Binder.

- Calibrated Power Output: 22.3 kW (30 HP) at 3600 RPM is standardized to the rated maximum engine capacity Baseline.

- Principal Torque Specification: Peak torque determines 64.4 N·m (47.5 ft. lb.) at 2400 RPM crankshaft output Requirements.

- Rated Displacement Volume: The engine cylinder requires 755 cc (46 cu. in.) for standard combustion chamber Threshold.

- Documented Compression Ratio: 9.4:1 is calibrated to maintain optimal fuel-air mixture pressure Mapping.

- Design Oil Capacity: System performance achieves 1.6–1.8 L (1.7–1.9 U.S. qt.) with filter installation Configuration.

- Nominal Engine Weight: Dry mass corresponds to 48 kg (105 lb.) for equipment mounting baseline Standards.

Professional Workshop Service Manual & Technical Specifications

Precision Technical Service Manual: Kohler Command Horizontal Engine (CH18-750) Operations-Manual

System-Coverage: CH18-750 horizontal crankshaft gasoline engine // System-Identifier: Fuel systems, electrical components, lubrication / Ignition and charging Logic // System-Coverage: Engine disassembly, inspection, reassembly procedures documentation.

| Component Category | Content Focus | Documentation Included |

|---|---|---|

| Fuel Systems | Carburetor, fuel pump, governor adjustments | Complete specifications and service procedures |

| Electrical Systems | Ignition modules, starters, charging | Circuit diagrams and component testing |

| Engine Mechanics | Crankshaft, pistons, valves, bearings | Clearance specifications and torque values |

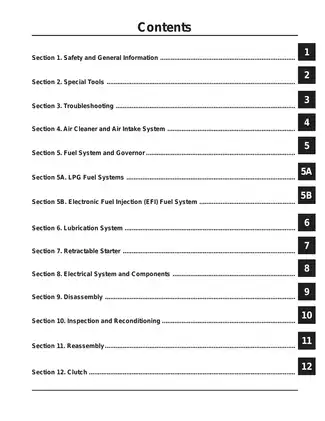

The service manual covers air cleaner and air intake system maintenance, fuel system components including carbureted and EFI configurations, lubrication system operation and service, retractable starter mechanisms, electrical system components and troubleshooting, and comprehensive engine disassembly and reassembly procedures. These sections address engine cooling, governor function, battery charging systems, spark plug specifications, and component inspection criteria.

Modular Nexus

Hydraulic schematics are included for valve lifter operation and crankcase pressure relief systems. The document provides wiring diagrams for CD ignition systems with fixed timing and SMART-SPARK™ electronic spark advance modules, as well as diagrams for both 15/20/25 amp regulated charging systems and 3 amp unregulated charging with optional 70 watt lighting circuits.

Operational Logic-Path

Steering component information is provided for governor linkage and throttle control assembly configurations. The manual documents mechanical governor design using centrifugal flyweight mechanisms, electronic governor control units, and digital linear actuator systems. Detailed adjustments address governor sensitivity repositioning, high-speed RPM setting procedures, and initial adjustment protocols for carburetor and EFI-equipped engines.

Precise Methodology

Inspection guidelines are provided for external engine condition assessment, crankcase vacuum testing, cylinder leakdown procedures, spark plug condition evaluation, and commutator surface examination. The document includes compression test alternatives, air cleaner element inspection protocols, fuel system functional verification, and battery voltage assessment procedures. Cleaning procedures address engine exterior surfaces, carburetor component restoration, ignition module terminal preparation, and starter commutator maintenance.

Core Standard

Alignment specifications are included for ignition module air gap positioning (0.28-0.33 mm nominal), crankshaft end play (0.070-0.270 mm with thrust bearing components), camshaft end play with shim (0.076-0.127 mm), and cylinder bore dimensional limits. The manual documents spark plug gap setting (0.76 mm), piston-to-piston pin clearance, and connecting rod-to-crankpin running clearance parameters across multiple engine displacement variants.

Advanced Topology

Reference data is included for engine identification number interpretation, oil viscosity selection based on ambient temperature ranges, fuel type recommendations (unleaded 87 octane minimum), and coolant/lubrication product specifications. The manual documents torque specifications for the crankshaft journal, cylinder head fastener assembly sequences, intake manifold mounting procedures, and closure plate fastener tightening to ensure proper joint separation prevention.

FAQ

Customer Reviews

Read what our customers say about this Kohler Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)