1985-1995 Kohler M18 / M20 Twin Cylinder Engine Service Manual (139 P.)

Comprehensive shop manual for Kohler M18 & M20 twin cylinder engines — covers 42.18 cu. in. M18 (18 hp @ 3600 RPM) and 46.98 cu. in. M20 (20 hp) specifications, torque settings, disassembly, reassembly, and troubleshooting procedures. TP-2204-B

Manual Preview

Sample pages from the 1985-1995 Kohler M18 / M20 Twin Cylinder Engine Service Manual (139 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Kohler M18 & M20 Twin Cylinder — 1985–1995 Documentary & Applied Vault | Magnum Series Packet.

- Designated Component Weight: Engine weight reaches 130 lbs (approximately) is configured at the factory baseline Benchmarks.

- Primary Precision Specs: For optimal displacement measurement, 42.18 cu. in. (M18) and 46.98 cu. in. (M20) produces the total rated displacement Range.

- Advanced Bolt Torques: Connecting rod nut is established at 140 in. lb. for new service fastening Sequences.

- Design Displacement Data: The cylinder head requires 15–20 ft. lb. torque for secure assembly Baseline.

- Engineered Circuit Specs: Bore diameter is set to 3.1245–3.1255 inches for standard cylinder specifications Requirements.

- Certified Size Parameters: Crankcase oil capacity reaches 1.5 U.S. quarts for proper lubrication Threshold.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Calibration Factory Manual: Engines (Gasoline) 1985-1995 Kohler M18 & M20 Twin Cylinder Engine Service Manual (139 Pages) Operations-Manual

Specification-Class: Kohler M18 & M20 Twin Cylinder — 1985-1995 // Procedure-Type: Maintenance and Technical Service Logic // Technical-Domain: Complete Engine Overhaul Documentation and Repair Specifications.

| Identifier | Technical-Path | Calibration-Standards |

|---|---|---|

| M18 Engine | Horsepower & Displacement Data | 18 hp @ 3600 RPM; 42.18 cu. in. displacement documented |

| M20 Engine | Horsepower & Displacement Data | 20 hp @ 3600 RPM; 46.98 cu. in. displacement documented |

| Oil System | Lubrication Specifications | Full-pressure system; 1.5 U.S. quarts capacity; torque data included |

| Fuel Delivery | Carburetor Systems | Kohler and Walbro carburetors; adjustment procedures documented |

| Ignition Module | Electronic Magneto System | .008/.012" air gap specifications included |

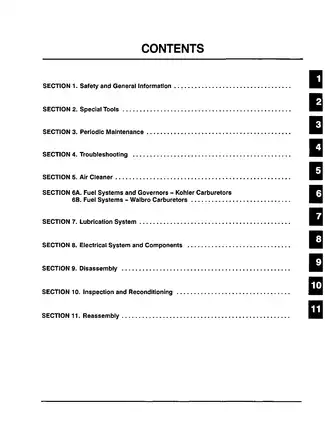

Organized into dedicated modules for disassembly, inspection, and reassembly procedures, this comprehensive technical reference encompasses fuel system fundamentals, electrical components, and lubrication pathways. The manual covers cylinder head and crankshaft systems, addressing inspection standards for valve clearances, piston-to-bore tolerances, and bearing surface specifications. Factory specifications are documented for connecting rod assemblies, oil pump operation, and governor mechanical linkage. Drivetrain specifications are addressed in sections detailing flywheel installation, starter motor operation, and ignition system troubleshooting methodology.

Technical chapters are organized around complete overhaul sequences with step-by-step disassembly instructions, component identification procedures, and detailed reassembly protocols. Valve guide removal and installation techniques are included alongside cylinder honing procedures, crankshaft end play verification, and camshaft timing mark alignment. The reference provides cylinder bore reconditioning pathways, piston ring installation standards, and compression testing protocols for both engine models across all specification variants.

Engine rebuild procedures are specified for cleaning cylinder walls following honing operations, measuring piston-to-bore clearance using precision instruments, and validating valve stem clearance within established tolerances. Reassembly procedures are specified for connecting rod installation with proper torque sequencing, crankcase sealing using silicone sealant application patterns, and oil pressure relief valve component placement. The manual documents torque specifications for the cylinder head fastener sequence to ensure proper flange face sealing and structural integrity during operation.

Technical Specifications Table:

| Section | Chapter Coverage | Reference Details |

|---|---|---|

| Safety & General Information | Engine identification, oil recommendations, fuel specifications | Includes crankcase oil capacity, SAE viscosity grades, fuel type guidelines |

| Periodic Maintenance | Oil changes, air cleaner service, spark plug inspection | Change intervals, filter replacement schedules, valve-to-tappet clearance procedures |

| Troubleshooting Guide | Starting problems, engine performance issues, electrical diagnostics | Compression testing, crankcase vacuum measurement, ignition module testing protocols |

| Fuel Systems | Kohler and Walbro carburetor adjustment, governor operation | Float level settings, idle speed adjustment, high speed stop bracket positioning |

| Lubrication System | Oil pump operation, pressure relief valve, oil filter installation | Full-pressure system documentation, oil sentry pressure monitor specifications |

| Electrical System | Magneto ignition, starter operation, battery charging systems | 15 and 25 amp regulated charging system wiring diagrams and troubleshooting |

| Disassembly & Reassembly | Complete engine tear-down and rebuild sequences | Component marking procedures, fastener torque sequences, seal installation depths |

| Inspection & Reconditioning | Cylinder bore honing, valve seat installation, piston ring service | Crosshatch pattern specifications, clearance measurement procedures, replacement part specifications |

FAQ

Customer Reviews

Read what our customers say about this Kohler Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)