Kohler Command CV17-750 Engine Service Manual

Complete service, troubleshooting, and maintenance guide covering fuel systems, ignition, lubrication, starters, electrical components, and full disassembly/reassembly procedures for CV17-750 vertical crankshaft engines.

Manual Preview

Sample pages from the Kohler Command CV17-750 Engine Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kohler Command CV17-750 — 2000–2007 Technical Service Reference | CV750 Series Module.

- Measured Power Output: 22.4 kW (30 HP) @ 3600 RPM is rated at the maximum engine performance Architecture.

- Integral Torque Data: Peak torque reaches 63.8 N·m (47.1 ft. lb.) @ 2600 RPM for crankshaft output Protocol.

- Operational Displacement: Engine cylinder volume provides 755 cc (46 cu. in.) capacity is specified as the swept volume Norms.

- Fundamental Compression Ratio: The combustion chamber requires 9.4:1 pressure setting supports optimal ignition conditions Bounds.

- Universal Oil Capacity: Lubrication system provides 1.6–1.8 L (1.7–1.9 U.S. qt.) with filter is calibrated to maintain engine protection Topology.

- Baseline Spark Plug Gap: Electrode spacing measures 0.76 mm (0.030 in.) is specified as the critical ignition parameter Standards.

Professional Workshop Service Manual & Technical Specifications

Advanced Workshop Training Manual: Kohler Command CV17-750 Engine - Service, Troubleshooting & Maintenance Handbook Reference-Archive

Repair-Classification: Kohler Command CV17-750 Vertical Crankshaft // Repair-Classification: Engine Service and Maintenance Operations Logic // Repair-Classification: Complete Technical Documentation with Comprehensive Specifications.

| Component | Operational-Logic | Validation-Data |

|---|---|---|

| Fuel System Architecture | Dual carbureted and EFI configurations documented | Float circuit, slow circuit, and main circuit specifications provided |

| Ignition System Framework | Electronic CD ignition and SMART-SPARK™ timing control | Module air gap and firing sequence documentation included |

| Lubrication Network | Full-pressure gerotor pump distribution system | Oil type, capacity, and maintenance interval data documented |

Organized into dedicated modules for Safety and General Information, Troubleshooting, Air Cleaner and Air Intake System, Fuel System and Governor, Electronic Fuel Injection, Lubrication System, Retractable Starter, and Electrical System and Components. The manual progresses through Disassembly procedures, Inspection and Reconditioning processes, and detailed Reassembly instructions.

Technical Benchmarks

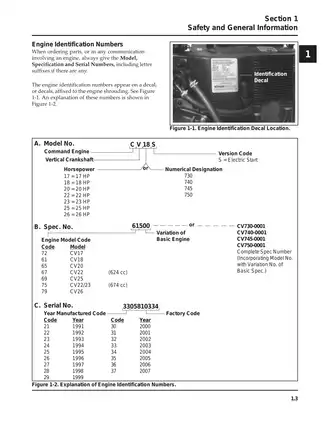

Factory specifications are documented for the Command CV17-750 series, which encompasses models from 12.7 kW (17 HP) through 22.4 kW (30 HP) displacement variants. The document includes engine identification procedures, detailing how to locate and interpret model numbers, specification codes, and serial number information on the engine decal. Torque specifications are extensively covered, with fastener recommendations organized by metric and English measurements for both standard applications and aluminum components. Power output data references the Society of Automotive Engineers Small Engine Test Code J1940 standard.

Diagnostic Methodology

Engine start and operation problems are addressed through systematic troubleshooting guides covering scenarios where the engine cranks but will not start, starts but does not keep running, starts hard, will not crank, runs but misses, will not idle, overheats, knocks, loses power, or uses excessive oil. External engine inspection procedures are documented to identify buildup of dirt and debris on cooling fins, inspect air cleaner components for damage, and evaluate oil condition by examining for metal chips and sludge accumulation. Oil pressure testing methodologies using water manometers and vacuum gauge kits are detailed, along with compression testing alternatives such as cylinder leakdown procedures that measure combustion chamber retention.

Advanced Framework

The air cleaner section addresses three different types: standard configuration with paper element and optional foam precleaner, commercial mower type with similar servicing requirements, and heavy-duty design featuring cylindrical housing with extended service intervals. Fuel system components covered include the pulse-type fuel pump, float-fed carburetor circuits, fuel shut-off solenoids, and high-altitude jet kits for operation above 1500 meters. Governor operation is explained through centrifugal flyweight mechanism principles, with both standard and governed idle systems addressed. The electronic fuel injection section encompasses the Motronic™ Engine Control Unit architecture, sensor input circuits, fuel injector spray patterns, fuel pressure regulation at 39 psi, and "closed loop" versus "open loop" operating modes.

Technical Protocol

Retractable starter servicing includes rope replacement without complete disassembly and pawl replacement procedures using spring tension release techniques. The electrical system covers spark plug specifications including gap settings, battery sizing recommendations based on ambient temperature, and charging systems available in 15-amp, 20-amp, 25-amp regulated, and 3-amp unregulated configurations. Electronic CD ignition and SMART-SPARK™ systems are documented with fixed timing operation and electronic spark advance control respectively. Troubleshooting procedures for both inertia drive and solenoid shift electric starters include drive service intervals, brush replacement protocols, and commutator inspection guidelines.

Modular Framework

The disassembly sequence establishes a logical progression beginning with spark plug lead removal and fuel system shutdown, continuing through removal of external components including air cleaner, carburetor, and starter motor, and progressing to internal engine work such as cylinder head, camshaft, and crankshaft extraction. The inspection and reconditioning section documents cylinder bore wear limits, piston ring gap specifications, valve guide removal and installation techniques, and bearing journal measurement standards. Documents torque specifications for the crankshaft, connecting rod fasteners, intake manifold mounting, and head bolts organized in multiple stages where applicable to ensure proper assembly stress control.

FAQ

Customer Reviews

Read what our customers say about this Kohler Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)