Beechcraft Bonanza 35 Series Shop Manual (D-1 to D-10119)

Complete aircraft maintenance procedures covering systems description, major disassembly, overhaul instructions, wiring diagrams, and periodic inspection schedules for the Bonanza 35 series aircraft.

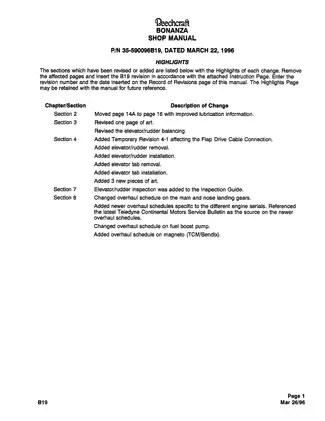

Manual Preview

Sample pages from the Beechcraft Bonanza 35 Series Shop Manual (D-1 to D-10119) manual

Purchase & Download

Models Covered & Key Technical Specifications

Beechcraft Bonanza 35 Series (D-1 to D-10119, except D-10097) — 1947–1996 Industrial Documentary Index | Bonanza Series Division.

- Established Fit Tolerances: Engine displacement reaches 185 to 520 cc is established at the cylinder volume Architecture.

- Operational Consumption Data: For fuel system compliance, 17 to 50 gallons usable is standardized to support extended range Parameters.

- Essential Thermal Limits: Manifold pressure dictates 32.5 inches Hg maximum operating envelope Standards.

- Baseline Linear Velocity: The landing gear retraction speed represents 80 to 90 mph airspeed requirement Margin.

- Integral Scan Resolution: Oil system capacity specifies 2.5 gallons (prior models) and 9 to 12 quarts (D-4866 and after) Protocol.

- Specific Adjustment Range: Flap travel reaches 20 to 35 degrees down position from neutral elevation Architecture.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Technical Manual: Beechcraft Bonanza 35 Series Aircraft Manual-Nexus

Diagnostic-Area: Beechcraft Bonanza 35 (D-1 through D-10119) // Engine-Type: Piston engine systems maintenance / Fuel injection and carburetor procedures Logic // Diagnostic-Area: Complete aircraft systems documentation with 480 pages of technical reference material.

| Document Category | Content Description | Coverage Details |

|---|---|---|

| Flight Control Systems | Aileron, elevator, rudder, and trim tab rigging procedures | Complete specifications provided |

| Landing Gear Operations | Hydraulic retract mechanisms, safety systems, door adjustment | See Chapter 3 and Chapter 4 |

| Fuel System Architecture | Bladder-type cells, boost pumps, selector valves, injection components | System overview and component data |

Service procedures are grouped by the fuel system architecture, the landing gear retract mechanisms, the flight control rigging documentation, and the electrical system component layout, encompassing all operational chapters from initial preflight procedures through emergency manual extension protocols. The manual documents the brake system hydraulic configurations, the oxygen system servicing intervals, and the air conditioning refrigerant recharge procedures, along with periodic inspection schedules for all major airframe systems. Lubrication specifications are included for the control column linkages, shock strut assemblies, and the landing gear actuator mechanisms, plus reference data for engine oil system maintenance and propeller governor adjustments.

Comprehensive Topology

Assembly instructions are detailed for the main and nose landing gear shock strut components, establishing proper shock fluid levels and air pressurization procedures. The document addresses the differential mechanism jig assembly positioning, the control column arm installation sequence, and the flap actuator motor connection points throughout the airframe.

Advanced Architecture

Hydraulic schematics are included for the brake system shuttle valve configurations, the landing gear position indicator circuits, and the optional stability augmentation system architecture. Cable tension graphs reference temperature-based adjustment protocols for the aileron, elevator, and rudder control systems, with maximum and minimum permissible values documented across the ambient air temperature range.

Core Logic-Path

Steering component information is provided for the nose wheel mechanical linkage, the nose gear torque knee assembly, and the assist step cable routing through the fuselage structure. The document establishes clearance requirements between the landing gear knee joint and the upper wing surface, plus adjustment procedures for the door actuating rods and the uplock roller bracket alignment.

Strategic Logic-Path

Inspection guidelines are provided for the fuel cell flapper valve operation, the brake lining wear determination protocols, and the flight control surface balancing procedures. The manual documents procedures for the aileron static moment measurement, the elevator and rudder counterbalancing weight installation points, and the trim tab neutrality verification using cable tension methods.

Engineered Protocol

The document references torque specifications for the fuselage bulkhead attachment bolts, the landing gear fitting fasteners, and the flap limit switch actuator hardware to ensure proper structural integration and control surface operation. Reference material addressing the brake master cylinder linkage geometry, the propeller deicing system pressure relief settings, and the engine fuel pump adjustment ranges are included to establish correct performance parameters across all aircraft configurations and serial variations from the early D-1 through the current D-10119 and later production series.

FAQ

Customer Reviews

Read what our customers say about this Beechcraft Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)