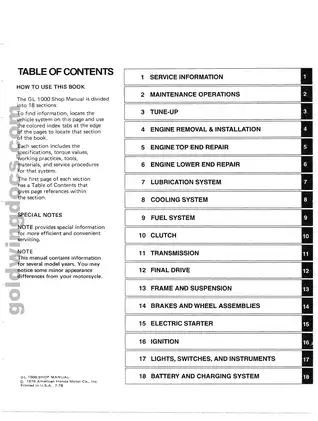

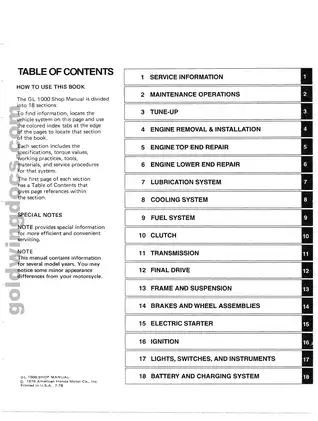

1976-1978 Honda Gold Wing GL1000 Shop Manual

Complete service guide for GL1000 maintenance—engine removal, cylinder head repair, transmission, final drive, brakes, frame suspension, electrical systems, and carburetor synchronization procedures.

Manual Preview

Sample pages from the 1976-1978 Honda Gold Wing GL1000 Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda GL-1000 — 1976–1979 Integrated Reference Manual for GL1000 Series Collection.

- Design Rotation Data: Maximum engine speed establishes the rated operational limit at 3200 rpm Bounds.

- Advanced Shipping Weight: For complete assembly specifications, 274 kg (604 Ibs) dictates the dry motorcycle weight Topology.

- Technical Maximum Resolution: Wheel base measures 1.545 m (60.9 in) across the frame centerline Matrix.

- Standard Fluid Levels: The radiator cooling system capacity reaches 3.2 liters (3.4 US quarts) Standards.

- Prescribed Wattage Specs: Engine displacement is set to 1100 cc (67 cu in) for the flat-four architecture Margin.

- Engineered Linear Velocity: The intake valve opening specification yields 5 degrees BTDC crankshaft rotation Protocol.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Reference Manual: Motorcycle Honda Gold Wing GL1000 Shop Manual (1976-1978) Calibration-Manual

Operational-Scope: Honda GL-1000 (1976-1979) // Operational-Framework: Service / Maintenance Logic // Operational-Scope: Complete technical documentation for water-cooled flat-four motorcycle engines.

| Aspect | Coverage | Documentation Status |

|---|---|---|

| Engine Systems | Cylinder heads, camshafts, lubrication circuits | Complete specifications provided |

| Transmission & Drive | Gear assemblies, clutch mechanisms, final drive hubs | Comprehensive service data included |

| Chassis Components | Frame, suspension systems, brake hydraulics | Full inspection and maintenance procedures |

Systematizing the service groups into engine fundamentals and suspension architecture encompasses fuel system documentation while electrical components and wheel assembly procedures establish the complete technical foundation and transmission maintenance overview concludes this comprehensive service reference.

Diagnostic Interface

The manual presents information on engine top-end repair procedures, including cylinder head disassembly and valve train inspection sequences. Service procedures are documented for crankshaft removal, piston inspection protocols, and bearing selection methodologies based on color-coded journal size classifications. The document addresses connecting rod clearance verification and main bearing installation within structured engine assembly sequences.

Systematic Nexus

Calibration requirements are specified for fuel system circuits, including carburetor synchronization procedures documented across multiple venturi bore configurations (755A through 771A models). Electrical system documentation covers dual ignition coil circuits, contact breaker point adjustments, and advance mechanism operation. Suspension service documentation covers front fork disassembly, steering head bearing replacement procedures, and rear shock absorber compression techniques across model year variations.

Core Interface

Service procedures are documented for clutch free-play adjustment, outer drum inspection protocols, and friction disc wear assessment. The manual includes transmission gear shift mechanism service, crankcase separation sequences, and shift shaft removal procedures. Cooling system documentation provides thermostat testing protocols, radiator core inspection methods, and fan motor continuity verification.

Engineered Sequences

Disassembly instructions are documented for brake master cylinder removal, piston cup replacement, and hydraulic line bleeding procedures. The reference includes wheel bearing retainer specifications, spoke torque data, and ComStar wheel inspection guidelines for both 1975-1977 and 1978-1979 model configurations. Final drive oil level checking procedures and hypoid gear maintenance data are systematically organized.

Comprehensive Methodology

The manual documents torque specifications for engine installation bolts, ranging from specifications for cylinder head fasteners to crankshaft pulley retention. Lubrication system sections cover oil pump inspection clearance measurements and scavenge pump operation principles. The document includes specific procedures for electrical connector testing, diode identification protocols, and alternator output voltage regulation specifications to ensure proper charging system function.

Sources for technical content derive from original Honda service documentation covering 332 pages of detailed mechanical and electrical system information organized across 18 primary service sections addressing motorcycle maintenance, diagnostics, and component repair methodologies.

FAQ

Customer Reviews

Read what our customers say about this Honda Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)