1998 Clark CMP 15/18 & CMP 20/25/30 Service Manual

1998 Clark CMP 15/18 & CMP 20/25/30 documentation including maintenance, diagnostics, and repair procedures. Part Number SM 638.

Manual Preview

Sample pages from the 1998 Clark CMP 15/18 & CMP 20/25/30 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Clark Forklift CMP 15/18 & CMP 20/25/30 Service Manual: (SM 638) - Comprehensive Forklift Maintenance, Diagnostics & Repair Manual (1998)

Forklift Service Data | Forklift Segment

- Documented Assembly Torques: 75-80 N-m (55-59 ft-lb) establishes the torque for the upright trunnion bolts Framework.

- Specific Temperature Range: For optimal operation, 82°C / 82°C defines the thermostat opening temperature Parameters.

- Essential Power Rating: 12 L (3.2 gal) -- signifies the transaxle oil capacity Threshold.

- Advanced Memory Capacity: The engine requires 4.0 L (4.2 qt) for the 4G63 model, detailing the engine oil capacity Logic.

- Core Speed Performance: Maximum throughput reaches 2600 rpm Parameters.

- Documented Fluid Volume: 8.5 L (2.25 gal) is the capacity of the cooling system fluid Framework.

Professional Workshop Service Manual & Technical Specifications

Clark Forklift CMP 15/18 & CMP 20/25/30 Service Manual: (SM 638) - Comprehensive Forklift Maintenance, Diagnostics & Repair Manual (1998)

Design-Core: Clark CMP 15/18 & CMP 20/25/30 (SM 638) // Operational-Scope: Forklift / Transaxle Logic // Design-Core: 1998 // Service-Nexus | Baseline | Calibration-Data

| Service-Nexus | Baseline | Calibration-Data |

|---|---|---|

| Engine Specifications | 1997 cc (121.8 cu in) | 1880 kPa (163.5 psi) at 300 rpm |

| Cooling System | 8.5 L (2.25 gal) | 0.85-1.12 kg/cm2 (12.1-15.9 psi) |

| Transaxle Specifications | 12 L (3.2 gal) | 173-310 kPa (25-45 psi) |

| Ignition System | 0.7-0.8 mm (0.027-0.031 in) | 4° BTDC at 800 rpm |

| Wheels and Tires | 861 kPa (125 psi) | 16.0-19.7 kgf-m (116-142 ft-lb) |

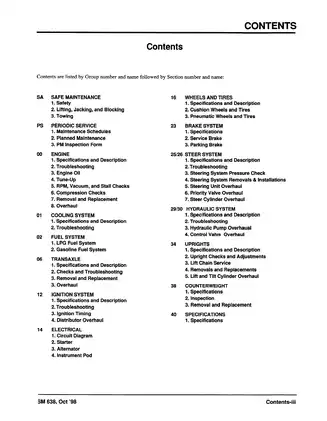

The manual presents information on engine systems, cooling systems, fuel systems, transaxles, ignition systems, electrical components, and wheels/tires. It details specifications, troubleshooting procedures, and overhaul guidelines for various forklift components. Careful attention is given to procedures such as engine tune-ups and ignition timing adjustments to ensure optimal performance and longevity.

Engine System Maintenance

This section systematically requiring basic planned maintenance procedures for the engine. It covers engine oil checks, coolant levels, and general inspections to maintain optimal engine condition. The manual documents torque specifications for engine components to ensure proper bearing preload accuracy.

Transaxle System Maintenance

This section covers the transaxle system, including removal, installation, and overhaul procedures. It details specifications for clutch pressure and hydraulic systems. Careful attention is given to ensuring correct component alignment and torque settings during assembly.

Ignition System Maintenance

This section focuses on the ignition system, detailing inspection, adjustment, and timing procedures. It covers distributor components, spark plug maintenance, and ignition coil tests to ensure proper spark delivery and engine timing.

Electrical System Maintenance

This section outlines the maintenance and overhaul of the starter, alternator, and instrument pod. It provides diagnostic guides and testing procedures for these electrical components to ensure reliable operation.

Wheels and Tires Maintenance

This section covers the maintenance and inspection of forklift wheels and tires. It details procedures for tire replacement, wheel mounting, and inflation, emphasizing safety precautions and correct component matching.

FAQ

Customer Reviews

Read what our customers say about this Clark Forklift manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)