Clark C500-35 through C500-55 Forklift Service Manual

Complete planned maintenance and adjustment procedures for Clark C500-35, C500-40, C500-45, C500-50, C500-55 forklifts. Includes detailed guidance for all systems. PN PMA 273.

Manual Preview

Sample pages from the Clark C500-35 through C500-55 Forklift Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

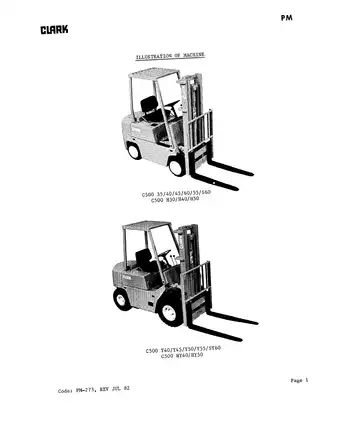

Clark C500-35 through C500-55 Forklift: Planned Maintenance & Adjustment Procedures Manual (C500 355 Series, PMA 273) for Clark Industrial Trucks Model-Portfolio: Clark C500-35 / C500-40 / C500-45 / C500-50 / C500-55 Forklift: Planned Maintenance & Adjustment Procedures Manual (C500 355 Series, PMA 273) for Clark Industrial Trucks // Operational-Scope: Planned Maintenance Procedures, Adjustment Procedures, Specifications, Lubrication Guides // Model-Portfolio: Clark Industrial Trucks System Documentation: 350 hours of operation and maintenance data provides comprehensive coverage of all forklift systems. Maximum Output Data: 250 operating hours defines the recommended interval for routine inspections and service. Measured Performance Benchmarks: 50 to 250 operating hours intervals are detailed for scheduled maintenance routines. Critical Functionality Mapping: All hydraulic systems must be regularly inspected and maintained in conformance with good practice. Universal Specifications Configuration: Capacity, operation and maintenance instruction plates, tags, or decals must be maintained in legible condition. Technical Standards Sequences: Industrial trucks must be kept in a clean condition to minimize fire hazards and help in the detection of loose or defective parts.

Professional Workshop Service Manual & Technical Specifications

Clark C500-35 through C500-55 Forklift: Planned Maintenance & Adjustment Procedures Manual (C500 355 Series, PMA 273) for Clark Industrial Trucks

Model-Portfolio: Clark C500-35 / C500-40 / C500-45 / C500-50 / C500-55 Forklift: Planned Maintenance & Adjustment Procedures Manual (C500 355 Series, PMA 273) for Clark Industrial Trucks // Operational-Scope: Planned Maintenance Procedures, Adjustment Procedures, Specifications, Lubrication Guides // Model-Portfolio: Clark Industrial Trucks

| Component | Diagnostic-Logic | Calibration-Standards |

|---|---|---|

| Hydraulic System Pressure | Checked every 50 hours | Relief Valve Setting indicated at 2000 PSI |

| Steering Adjustments | Adjusted for free play | Upright racking eliminated through yoke nut torque |

| Brake Adjustment | Checked for free travel | Pedal free travel set to 1/8" as per specifications |

| Tire Maintenance | Inspected for damage and wear | Lock ring ensured for proper seating during inflation |

| Parking Brake Adjustment | Checked for holding power on 15% grade | Lever adjustment on brake assembly ensures solid contact |

| Carriage Roller Adjustment | Checked for squareness and clearance | Angle checked with Sliding T Bevel, adjusted with shims |

The repository is divided into several major sections, detailing procedures for engine tune-up, cooling system maintenance, and various component adjustments. Key systems covered include the steering, brakes, and hydraulic systems, offering systematic guidance for optimal machine performance and longevity.

Diagnostic Procedures are covered for the engine, including checks for proper timing, oil levels, and air cleaner condition to ensure efficient operation and prevent power loss.

Wiring diagrams are provided for the entire electrical system, ensuring correct connections for all components and facilitating troubleshooting of any electrical faults.

Fuel system procedures are documented for carburetor and governor adjustments, ensuring the engine operates at specified RPMs and maintains proper fuel-air mixture for optimal performance.

Adjustment procedures are detailed for the steering system, including checking and adjusting pitman arm stops, hand wheel play, and linkage looseness to ensure safe and precise steering control.

Timing procedures are documented for the ignition system, covering checks for spark advance and distributor timing to ensure proper engine operation and starting.

Systematically requiring consistent maintenance ensures the longevity and operational efficiency of your Clark forklift. This manual details the necessary procedures to keep your equipment in top working condition, covering everything from basic checks to complex adjustments.

This manual documents torque specifications for steering gear mounting bolts to ensure proper bearing preload accuracy.

FAQ

Customer Reviews

Read what our customers say about this Clark Forklift manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)