Mitsubishi TD025 / TD03 / TD04 / TD05 / TD06 Turbocharger Service Manual

Field service reference for Mitsubishi TD025, TD03, TD04, TD05, and TD06 turbochargers, detailing construction, maintenance, and troubleshooting for optimal engine performance.

Manual Preview

Sample pages from the Mitsubishi TD025 / TD03 / TD04 / TD05 / TD06 Turbocharger Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Mitsubishi Turbocharger Service Manual: TD025 / TD03 / TD04 / TD05 / TD06 - Diagnostic & Repair Procedures

TD025 / TD03 / TD04 / TD05 / TD06 (401701) -- N/A Detailed Certified Digest | Turbocharger Record.

- Prescribed Tolerance Values: 0.37 mm is rated at the maximum bearing clearance Value.

- Standard Interference Fit: For optimal reassembly, 0.15 kgf·m governs the torque specification Framework.

- Maximum System Specs: The compressor wheel requires 0.046 mm for proper clearance Logic.

- System Calibrated Norms: The shaft & turbine wheel establishes the standard runout bounds Topology.

- Calibrated Clearance Data: For assembly, 0.032 mm defines the thrust bearing clearance Protocol.

- Nominal Production Rate: 1.5 – 2.5 kgf·m signifies the tightening torque for lock nuts Threshold.

Professional Workshop Service Manual & Technical Specifications

Mitsubishi Turbocharger Service Manual: TD025 / TD03 / TD04 / TD05 / TD06 - Precision Diagnostic & Repair Procedures

Machine-Range: TD025 / TD03 / TD04 / TD05 / TD06 // Model-Portfolio: Turbocharger / Engine Component Logic // Machine-Range: Service Manual.

Technical Data Overview

| Integrated-Framework | Technical-Path | Calibration-Spec |

|---|---|---|

| Rotor Assembly | Shaft & Turbine Wheel | Repair Limit |

| Compressor Housing | Bearing Housing | Service Limit |

| Turbine Housing | Piston Ring | Assembly Standard |

Contents

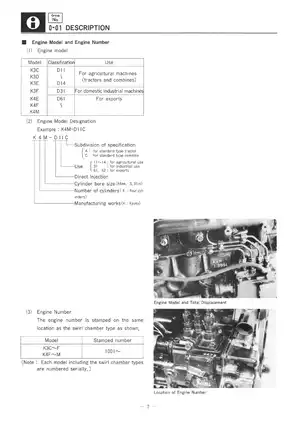

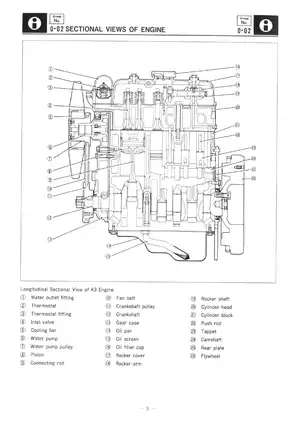

Technical units are distributed across the following sections: Disassembly, Cleaning and Inspection, Reassembly, and Troubleshooting. Each section details specific procedures and components. Key maintenance standards and tightening torques are also provided for reference, ensuring accurate service.

Systems and Procedures

The disassembly section documents the step-by-step removal of turbocharger components, including the actuator, turbine housing, and compressor wheel. Cleaning and inspection procedures are detailed for assessing the condition of bearings, shaft, and housing. The reassembly section guides users through the correct installation of parts, emphasizing the importance of proper clearances and torque values. Troubleshooting covers common symptoms like rough running and excessive smoke, providing likely causes and remedies. The manual documents torque specifications for the compressor wheel lock nut and coupling assembly nut to ensure proper gasket seal integrity.

FAQ

Customer Reviews

Read what our customers say about this Mitsubishi Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)