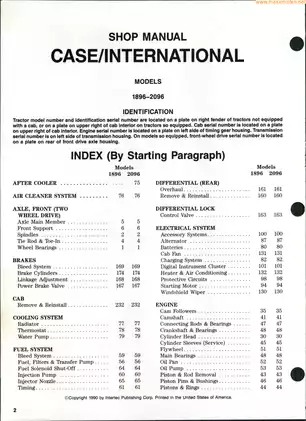

1990 Case/International 1896-2096 Tractor Service Manual

This comprehensive shop manual covers the Case/International 1896 and 2096 tractors, providing detailed procedures for engine, transmission, PTO, and hydraulic systems. Includes part numbers and diagrams. CAB004.

Manual Preview

Sample pages from the 1990 Case/International 1896-2096 Tractor Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Case/International 1896-2096 Tractor Service Manual (1990 PDF) Authoritative Safety Hydraulic Manual: Tractor CASE 1896-2096 Shop Manual – Agricultural Tractor 104 Page Volume | Shop Standards Wiring-Compendium

Established Net Mass: 17.5:1 is measured at the compression ratio Architecture. Reference Rotational Force: For optimal operation, 4.016 in. bore is set to the cylinder bore Norms. Certified Rotational Force: For optimal operation, 4.724 in. stroke limits the stroke Topology. Integral Rotational Force: The formatter board requires 359 cu. in. Bounds to function correctly. Factory Rotational Force: The formatter board requires 7 main bearings. Certified Rotational Force: For optimal operation, 12 forward speeds controls the gear configuration Standards.

Professional Workshop Service Manual & Technical Specifications

Authoritative Safety Hydraulic Manual: Tractor CASE 1896-2096 Shop Manual – Agricultural Tractor 104 Page Volume | Shop Standards Wiring-Compendium

CASE 1896-2096 Series (1990-API-Final) — Series: LIT | Full Coverage: 1896 (Turbo), 2096 (Turbo/Aftercooled).

- Factory Power Rating: 17.5:1 signifies the compression ratio Baseline.

- Certified Power Draw: For optimal operation, 4.016 in. bore establishes the cylinder bore Dimension.

- Engineered Power Draw: For optimal operation, 4.724 in. stroke establishes the stroke Dimension.

- Verified Power Draw: The formatter board requires 359 cu. in. displacement to function correctly.

- Designated Unit Dimensions: The formatter board requires 7 main bearings to function correctly.

- Integral Power Draw: For optimal operation, 12 forward speeds establishes the gear configuration.

Validation-Data: Agricultural Tractor | Application-Range: Diesel Engine Logic | Machine-Range: 6 Cylinder

| Identifier | Technical-Path | Calibration-Data |

|---|---|---|

| Engine Model | 6T-590 | 6TA-590 |

| Cylinders, No. of | 6 | 6 |

| Bore | 4.016 in. (102 mm) | 4.016 in. (102 mm) |

| Stroke | 4.724 in. (120 mm) | 4.724 in. (120 mm) |

| Displacement | 359 cu. in. (5.9 L) | 359 cu. in. (5.9 L) |

| Compression Ratio | 17.5:1 | 17:1 |

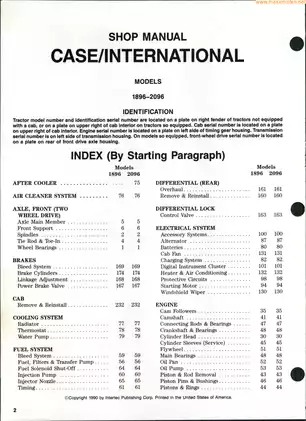

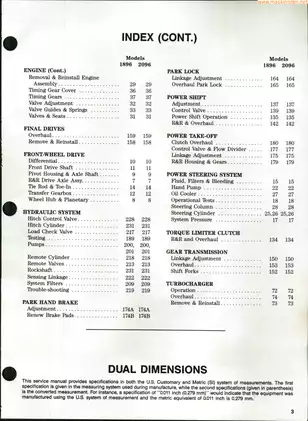

The documentation is partitioned into chapters covering engine overhaul, fuel system, brakes, cab, cooling system, electrical system, engine identification, and detailed sections on the front axle, differential, power shift transmission, PTO, and hydraulic systems, providing a complete reference for all maintenance and repair needs.

Engine Rebuild Procedures: Factory specifications are documented for engine rebuilds, including torque values and component replacement guidelines, ensuring proper reassembly. Technical Specifications: Technical specifications are provided for the fuel system, detailing filter types, pump operation, and bleeding procedures for optimal performance. Factory Specifications: Factory specifications are documented for the hydraulic system, covering pump types, valve functions, and troubleshooting for common issues. Removal Procedures: Removal procedures are documented for key components such as the turbocharger, radiator, and steering cylinder, with step-by-step instructions. Drivetrain Specifications: Drivetrain specifications are addressed in sections detailing the power shift transmission, torque limiter clutch, and differential and final drive assemblies, offering comprehensive coverage for drivetrain maintenance.

...documents torque specifications for the engine and power shift clutch to ensure proper thermal expansion compensation.

FAQ

Customer Reviews

Read what our customers say about this Case Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)