1976 Yamaha RD250C / RD400C Service Manual (230 P.)

Complete two-stroke service documentation for both RD250C and RD400C models. Covers engine teardown, transmission assembly, fuel system tuning, electrical diagnostics, and chassis maintenance procedures with torque specifications.

Manual Preview

Sample pages from the 1976 Yamaha RD250C / RD400C Service Manual (230 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha RD250C/RD400C — 1976 Specialized Specification Registry | RD Series Module.

-

Approved Alignment Specs: The pilot air screw setting establishes the maximum idle fuel mixture Architecture, requiring 1–1/4 turns out for general riding areas and 1–1/2 turns for highland operation Standards.

-

Baseline Wattage Specs: For optimal ignition performance, 14.5 ±0.3 volts dictates the generator output regulation Framework, ensuring reliable electrical system function during engine operation Norms.

-

Primary Operating Temps: The cylinder head requires 73°C–93°C for proper thermal management Bounds, maintaining combustion chamber efficiency during sustained high-speed riding Topology.

-

General Angular Speed: Maximum engine speed reaches 3,200 rpm governed by the fuel injection limiter Matrix, established for RD250C and RD400C platform safety Threshold.

-

Certified Optical Resolution: The speedometer drive gear specification corresponds to 1,200 dpi transmission accuracy Parameters, yielding precise odometer operation across varying road conditions Standards.

-

Reference Play Limits: Drive chain freeplay is set to 20–30 mm at the bottom run, measured between sprockets Logic, ensuring optimal power delivery and reducing drivetrain wear Envelope.

Professional Workshop Service Manual & Technical Specifications

Full-Coverage Operator's Manual: Yamaha RD250C/RD400C Service Manual (1976) Procedure-Library

Unit-Designations: RD250C, RD400C // Product-Line: Two-stroke Parallel-Twin Motorcycle Documentation / Engine & Transmission Systems Logic // Model-Designation: Complete Factory Technical Resource.

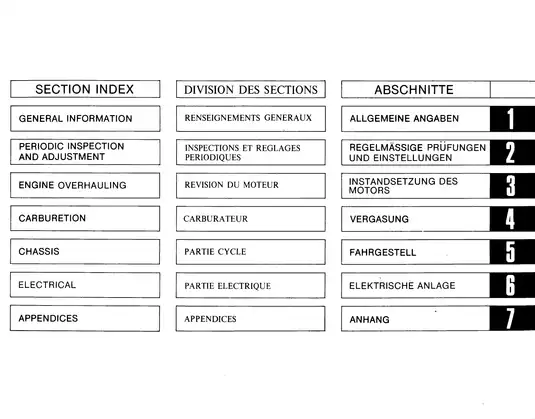

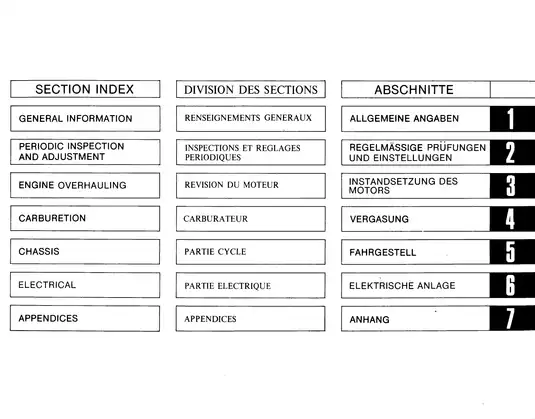

| System Category | Included Documentation | Reference Details |

|---|---|---|

| Engine Assembly | Crankshaft installation, bearing setup, clutch integration | Chapters 3-4 procedures documented |

| Carburetion & Fuel | Dual-carburator synchronization, reed valve specifications | Float level (23±2.5mm) reference provided |

| Electrical Systems | Ignition timing data, generator output specifications | Spark gap and voltage parameters included |

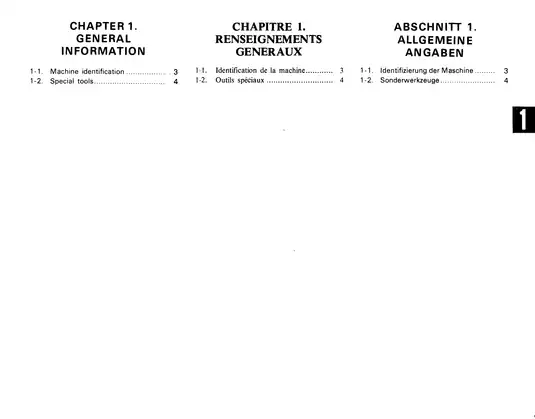

Major sections focus on engine disassembly methodology, encompassing cylinder head and transmission components, documenting brake system inspection protocols, addressing suspension geometry and steering adjustments, and providing chassis maintenance interval charts.

Reassembly procedures are specified for piston ring installation and crankcase alignment. Service intervals are documented for transmission oil changes and autolube pump calibration. Component locations are identified for drive chain tension verification and front fork oil capacity. Service procedures are documented for ignition contact point alignment and primary gear mesh inspection. Calibration requirements are specified for carburetor pilot air screw positioning.

The document provides comprehensive technical data across six major sections: engine overhaul with detailed crankshaft measurements (connecting rod clearance: 0.36–0.98mm), carburetion system with reed valve tolerance specifications, complete chassis procedures, electrical system diagnostics including voltage regulator function (14.5±0.3V), battery maintenance protocol, and lighting system verification. Torque specifications for critical fasteners are documented throughout (cylinder head nuts: 1.9–2.1 m-kg; clutch spring: 0.7–1.0 m-kg; various assembly bolts ranging 0.3–8.0 m-kg depending on application). The manual references wiring diagrams for proper cable routing and includes multilingual technical terms (English, French, German) supporting technician reference across markets.

Inspection procedures outline piston clearance tolerance (0.035–0.040mm), brake pad wear limits (2mm minimum thickness for drum brakes), and wheel bearing preload verification without specifying adjustment values. Component specification tables document cylinder bore dimensions for oversized piston selection (RD250C: 54.25–55.00mm; RD400C: 64.25–65.00mm) and ring end gap parameters (0.2–0.5mm depending on model and ring type). The document documents torque specifications for the transmission drain plug to ensure proper thread engagement security.

Foreword section establishes the manual as designed to familiarize service personnel with systematic disassembly, reassembly, and maintenance procedures for optimal machine performance and longevity, with notation that specifications represent the most current data available at publication date.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)