IHI 35N Excavator Parts Catalog (297 P.)

Master parts reference covering all IHI 35N mini-excavator assemblies and systems. Complete hydraulic, engine, and attachment specifications with serial number tracking for optimal parts identification.

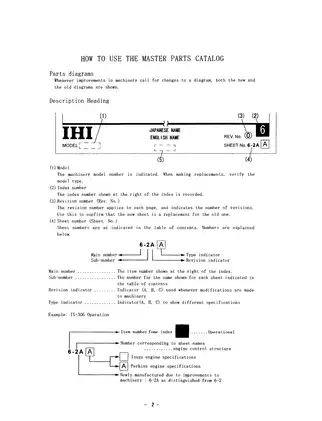

Manual Preview

Sample pages from the IHI 35N Excavator Parts Catalog (297 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

IHI 35N Excavator — Serial WM000001

Procedural Reference & Engineering File.

- Nominal Torque Data: Hydraulic cylinder fasteners require M12×30 P=1.25 mm pitch bolts rated at 112 N·m minimum tension Requirements.

- Principal Displacement Capacity: The main traction motor achieves displacement specifications of 17 L (4.5 gal) transaxle volume for hydraulic fluid circulation Threshold.

- Rated Pressure Setting: Swing drive hydraulic relief valve is standardized to 9860–10825 kPa (1430–1570 psi) system protection Mapping.

- Technical Hose Dimensions: Control piping assemblies specify hose bore ID of 3/8 inch (PF3/8) to 1/4 inch (PF1/4) reducer fittings Configuration.

- Standard Seal Ring Specification: Hydraulic system "O" rings reach P12.5-70B profile diameter of 12.5 mm nominal seal dimension Benchmarks.

- Design Cylinder Bore: Boom cylinder assembly determines 115 mm (4.5 in) bore diameter with 100 mm stroke length at N12×30 P=1.25 fastener interface Range.

Professional Workshop Service Manual & Technical Specifications

Factory-Level Safety Manual: Excavator Master Parts & Service Reference: IHI 35N Excavator System-Standards

Operational-Framework: IHI 35N Excavator models // Equipment-Series: Compact mini-excavator systems, tracked crawler machinery // System-Identifier: Complete assembly documentation with parts cross-reference.

| Metric | Technical-Path | Calibration-Standards |

|---|---|---|

| Lower Machine Assembly | Frame, rollers, crawler shoes, drive components | Sheet 1-1 through 1-7 |

| Turntable & Swing Bearing | Rotating superstructure, slew ring bearings | Sheets 2-1 |

| Hydraulic Piping | Return, suction, control, boom swing circuits | Sheets 4-1 through 4-4 |

| Hydraulic Instruments | Traction and swing motors, cylinders, manifolds | Sheets 5-1 through 5-14 |

| Operating Controls | Levers, switches, engine throttle assemblies | Sheets 6-1 through 6-4 |

Technically calling for precision in parts identification, this master catalog documents the structural composition of the IHI 35N compact excavator across fourteen distinct sections. Service procedures are grouped by mechanical subsystem: the lower machine assembly covers crawler shoes, drive mechanisms, and traction rollers; the turntable section addresses swing bearings and rotary components; hydraulic piping assemblies detail return, suction, control, and boom swing circuits; and hydraulic instruments encompass traction motors, swing motors, and control valve assemblies.

The document includes coverage of operating controls including traction levers, control levers with both standard and short-lever configurations, blade and boom swing controls, and engine control assemblies with deceleration options. Repair information is provided for power unit components—engine mounting, air cleaner, muffler, oil pump drive, and fuel system assemblies. Blade attachment specifications are included for the hoe attachment system, boom swing mechanisms, hoe bucket assemblies, and blade attachment configurations.

Verification procedures are included for cab-related assemblies: operator seating, canopy and cover systems, noise absorption panels, instrument panel wiring, and electric system components with battery, light, and horn assemblies documented. The catalog provides detailed component listings for the operator room with windows, doors, climate control, and interior trim; name plate specifications in multiple language configurations (English, Dutch, French, Italian, German, Danish); and mirror and light mounting arrangements.

Brake system specifications are included for all hydraulic circuits through their control valve assemblies and manifold configurations. Safety procedures are documented for traction alarm devices and interlocking mechanisms. The document provides an exhaustive parts index organized by part number with corresponding sheet and key numbers for rapid cross-referencing, enabling technicians to identify components, verify interchangeability across serial ranges, and locate replacement specifications.

FAQ

Customer Reviews

Read what our customers say about this IHI Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)