IHI 40NX / 45NX Mini Excavator Parts Catalog (361 P.)

Parts diagram specifications covering crawler shoes, turntable assemblies, hydraulic piping, cylinders, and control systems for IHI mini excavators models 40NX and 45NX with complete interchangeability documentation.

Manual Preview

Sample pages from the IHI 40NX / 45NX Mini Excavator Parts Catalog (361 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

IHI 40145NX & 45NX Mini Excavator — 2016–2020 Precision Engineering Vault | 40145NX Series Repository.

- Authorized Circuit Specs: 1590 cc (97 cu in) is specified as the engine cylinder volume Mapping.

- Published Heat Tolerance: For optimal operation, 15–30°C defines the environmental limit Configuration.

- Reference Processing Speed: Maximum throughput reaches 3200 rpm Benchmarks.

- Established Resolution Data: The hydraulic system requires 17 L (4.5 gal) for transaxle capacity Range.

- Measured Twist Specifications: Relief valve setting reaches 9860–10825 kPa (1430–1570 psi) Sequences.

- Core Power Framework: Operating envelope spans 20.9 kW (28 hp) maximum rated flywheel output Baseline.

Professional Workshop Service Manual & Technical Specifications

Unified Technical Installation Manual: Mini Excavator IHI 40NX / 45NX Excavator - Comprehensive Parts Catalog & Service Guide Procedure-Library

Technical-Scope: IHI 40NX / 45NX Models (2016-2020) // Reference-Category: Parts assembly and component systems documentation / Structural and mechanical components // Machine-Range: Compact excavation machinery with detailed component interchangeability reference.

| Component | System-Path | Framework |

|---|---|---|

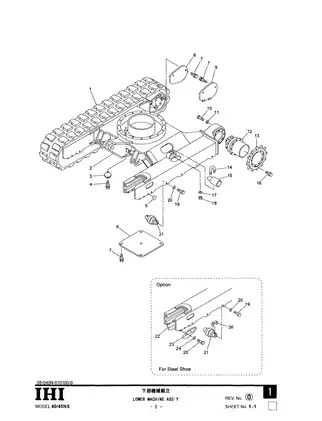

| Lower Machine Assembly | Track and undercarriage systems | Complete structural documentation |

| Hydraulic Piping Networks | Pressure distribution and control circuits | Documented pressure specifications |

| Motor and Valve Assemblies | Power transmission and flow regulation | See Sections 5 and 16 |

| Boom, Arm, and Bucket Cylinders | Hydraulic actuator systems | Dimensional data provided |

| Control Systems | Operator interface and remote functions | Electrical and mechanical specifications |

Repair data is categorized into systematic sections addressing the lower machine foundation, turntable rotation bearings, swing drive motor assemblies, and the complete hydraulic piping network that manages pressure distribution across all machine functions. The documentation provides guidance on boom and arm cylinder systems, bucket rotation control assemblies, and blade attachment configurations that support variable work tool integration.

Clearance measurements are addressed for all track and roller assemblies to maintain proper tension during extended operations. Special procedures are addressed for the swing bearing, which includes lubrication point identification and seal replacement data. Verification procedures are included for the control valve assembly, documenting the relationship between pilot pressure circuits and main spool actuation. Repair information is provided for the remote control valve assembly, including seal kit specifications and component replacement sequence. The document includes coverage of engine and transmission systems, fuel tank piping assemblies, and air cleaner installation paths that integrate with the engine mounting interface.

The manual documents torque specifications for the lower roller bearing assemblies to ensure proper oscillation integrity. Sections address the operating controls including traction lever assembly, control lever configuration for boom and arm functions, blade and boom swing manual control, engine throttle control assembly, and the spare port piping option for auxiliary hydraulic circuits. Complete electrical system documentation encompasses battery installation, instrument panel assembly, safety relay configuration, and warning light circuit integration. The documentation includes operator room configurations with canopy, cabin, and tops variants, providing mounting hardware specifications, window and seal assembly data, and climate control system component listings.

The parts catalog maintains interchangeability cross-reference data across production years (2016–2020 model span), indicating which components function across equipment serial number ranges and which require model-specific variants. Hoe attachment options are documented with bucket capacity specifications (0.07–0.15 cubic meters), boom swing mechanism assembly data, and articulated arm configuration alternatives. Crane specification sections address hydraulic piping for lifting operations, hook block assembly components, angle indicator detector systems for load monitoring, and electrical control systems for power-assisted operations. The index of parts numbers arranged in sequential order provides reference location data across 368 pages, facilitating location of specific components within their respective assembly section.

FAQ

Customer Reviews

Read what our customers say about this IHI Mini Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)