2007 Gilera Fuoco 500 i.e. Service Manual (396 P.)

Complete service documentation for Fuoco 500 i.e. covering maintenance, repair procedures, and technical specifications. Detailed engine, transmission, and electrical system guidance with diagnostic procedures.

Manual Preview

Sample pages from the 2007 Gilera Fuoco 500 i.e. Service Manual (396 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Gilera Fuoco 500 i.e. — 2007 Industrial Applied Primer | Fuoco 500 Series Kit.

- Published Assembly Gap: Valve clearance is measured at 0.15 mm (engine cold) establishes the intake valve positioning Margin.

- Measured Load Capacity: For optimal lubrication, 1.7 l defines the engine sump oil volume Protocol.

- Integral Thermal Envelope: 493 cm³ limits the maximum engine displacement capacity Architecture.

- Operational Size Parameters: Tank capacity reaches 12 l (~2 l reserve) maintains the fuel supply Norms.

- Fundamental Fastening Values: Torque specification 44 Nm at 5,200 rpm controls the maximum engine output Bounds.

- Universal Running Clearance: Crankshaft-bushing maximum clearance admitted 0.08 mm ensures bearing precision Topology.

Professional Workshop Service Manual & Technical Specifications

Authoritative Diagnostic Manual: Maxi Scooter Gilera Fuoco 500 i.e. 2007 Precision Maintenance & Repair Manual Reference-Archive

Model-Designation: Fuoco 500 i.e. (2007) // Series-Validation: Electronic fuel injection with integrated ignition control Logic // Engineering-Metrics: Four-stroke single-cylinder engine, 493 cc displacement, automatic CVT transmission with hydraulic tilt-lock suspension.

| Specification | System-Path | Logic |

|---|---|---|

| Engine Type | Single-cylinder 4-stroke, dual spark plugs | Electronic management via MIU control unit |

| Displacement | 493 cc | Four-valve, overhead cam timing chain |

| Power Output | 29 kW at 7,500 rpm | Fuel injection, electronic ignition advance |

| Transmission | Automatic variator with torque limiter | V-belt drive, self-ventilating dry clutch |

| Braking System | Dual 240 mm hydraulic discs | Front and rear calliper control from handlebars |

| Suspension | Tilt-lock articulated parallelogram | Hydraulic system with electronic control unit |

| Cooling | Forced circulation with electric fan | Thermostat-managed radiator and expansion tank |

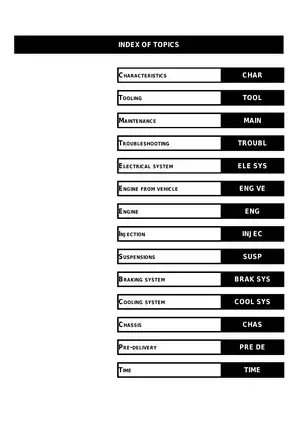

Outlining the operational framework across the characteristics section introducing general specifications and safety protocols, the manual progresses through tooling requirements and specialized equipment documentation, continues with comprehensive maintenance schedules aligned to service intervals, incorporates troubleshooting procedures for mechanical and electrical faults, addresses electrical system architecture and immobilizer programming, and concludes with detailed removal-reinstallation sequences for engine assemblies, transmission components, suspension mechanisms, and braking circuits while providing dimensional verification procedures and component inspection criteria throughout.

Service intervals are documented for engine oil changes, transmission fluid replacement, brake fluid circulation, coolant system maintenance, spark plug intervals, and brake pad wear assessment across 2,000 km through 80,000 km operational milestones. Reassembly procedures are specified for piston-cylinder assemblies following ring installation and gasket thickness selection based on piston crown position relative to cylinder head plane. Component locations are identified for fuel pump and pressure regulator positioning within the tank assembly, immobilizer aerial placement on the shield back plate, electronic control units mounted in the helmet compartment, and sensor distribution across engine and chassis frameworks.

Valve clearance adjustment requirements are documented at 0.15 mm for both intake and exhaust circuits with cold-engine verification procedures. Calibration requirements are specified for lambda probe oxygen sensing (350-600°C operating temperature), throttle position sensor reset procedures requiring diagnostic tester interface, and fuel pressure maintenance at 3 bar throughout the injection circuit. The document references torque specifications for critical fasteners including steering components, driving pulley assembly, clutch ring fastening, flywheel retention, cylinder head studs with progressive tightening sequences, and rear wheel axle fastening, ensuring proper component alignment retention.

Wiring diagrams depict ignition circuits, battery recharge systems, fuel pump activation sequences, lighting and turn indicator control architecture, instrument panel signal conditioning, and tilt-locking electronic system integration with parking control unit logic. Diagnostic procedures address immobilizer LED flash codes (1-flash serial line detection, 2-flash transponder signal, 3-flash key recognition), Virgin circuit programming methodology for service key storage (maximum 7 keys), and control unit status verification through connector pin voltage measurement. Oil pump specifications document trochoidal rotor design with radial clearance parameters, by-pass piston calibration, pre-filter mesh configuration, and cartridge filter anti-cavitation valve operation during cold-engine and high-rpm load conditions.

The manual provides cooling system layout including forced-circulation pump control via countershaft, two-way thermostat positioning, horizontal-flow radiator operation, expansion tank venting architecture, and electric fan activation at 105°C thermostat-managed threshold. Suspension mechanism documentation covers hydraulic tilt-lock system pressure distribution, geared motor control interface, potentiometer angle calibration, sliding stem locking device operation, and brake disc sector mechanical positioning. Brake system chapters document dual-calliper front disc architecture with floating-body piston action, rear single-calliper configuration, pad wear limits at 1.5 mm minimum thickness, and hydraulic bleeding procedures using vacuum-assisted pump technology.

Electrical system sections include 12-volt sealed battery specifications (14 Ah capacity, 125 A starting current), twelve-circuit fuse protection architecture with dedicated loads for injection components, fuel pump relay control, horn activation, lighting circuits, and immobilizer aerial integration. Transmission chapters address automatic variator pulley bearing inspection, clutch spring free-length measurement (minimum 120 mm), belt width tolerance (27.5-28.7 mm), and roller housing clearance verification with specialized extraction tools. Final reduction gear chapters document hub cover bearing replacement procedures, countershaft dimension checking, oil seal installation methodology, and gear tooth inspection for wear assessment across transmission side components.

FAQ

Customer Reviews

Read what our customers say about this Gilera Maxi Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)