1997 Komatsu PC200LC-6 / PC210LC-6 / PC220LC-6 / PC250LC-6 Shop Manual (719 P.)

PC200LC-6 service documentation with hydraulic pump control, swing machinery, track frame systems, and CLSS load sensing valve operation. PN CEBM001001

Manual Preview

Sample pages from the 1997 Komatsu PC200LC-6 / PC210LC-6 / PC220LC-6 / PC250LC-6 Shop Manual (719 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Komatsu PC200LC-6 / PC210LC-6 / PC220LC-6 / PC250LC-6 — 1997 Structured Automotive Blueprint | Excavator Packet.

- Factory Rotational Force: The engine crankshaft delivers 564 N·m (57.5 kgm) at 1600 rpm is calibrated to provide maximum hydraulic pump input Benchmarks.

- Essential Storage Capacity: Hydraulic tank volume reaches 230 L (60.8 US gal) for the main circuit supports continuous excavation Ranges.

- Key Fit Tolerances: Valve clearance specifications establish 0.254 mm intake and 0.508 mm exhaust valve adjustments establishes precise engine breathing Sequences.

- Verified Climate Specs: Engine coolant maximum operating temperature is designed for 100°C rated system thermal balance Baseline.

- Designated Travel Rate: Maximum travel speed achieves 5.5 km/h (Hi speed, no load) is specified as peak crawler ground velocity Requirements.

- Approved Clamp Forces: Main relief valve set pressure defines 34.79 MPa (355 kg/cm²) for two-stage pressure control defines maximum system safety threshold Threshold.

Professional Workshop Service Manual & Technical Specifications

Thorough Training Assembly Manual: Excavator Komatsu PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 (1997) - Comprehensive Hydraulic Excavator Shop Manual Operations-Manual

Model-Portfolio: PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 (1997) // Operational-Scope: Hydraulic Excavator / Pump, Motor, Cylinder Systems Logic // Series-Validation: Complete technical documentation for maintenance, testing, and troubleshooting procedures.

| Integrated-Framework | System-Path | Context |

|---|---|---|

| Engine Assembly and Thermal Management | S6D102E-1 and SA6D102E-1 Diesel Engines | Specifications documented for all models |

| Hydraulic Pump Configuration | Variable Displacement Piston Type (Dual Pump System) | PC valve and LS valve control mechanisms included |

| Control Valve Architecture | 6-spool and 9-spool Configurations | Load-sensing and pressure-compensation documented |

| Actuator Systems | Travel Motors, Swing Motors, Work Equipment Cylinders | Theoretical delivery and safety valve specifications provided |

| Power Transmission | Final Drive Reduction Gearing | Planetary gear ratios documented for PC200/210 and PC220/250 variants |

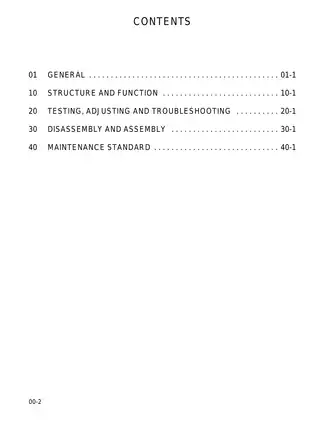

Maintenance information covers engine-related components including damper assemblies, radiator configurations, and cooling system specifications. Service procedures are grouped by functional module: the engine block details both S6D102E-1 (104 kW at 2000 rpm) and SA6D102E-1 (124 kW at 2100 rpm) variants with their respective valve clearance and compression specifications. Drivetrain specifications are addressed in sections covering the final drive planetary gear systems, swing machinery reduction ratios, and track frame assemblies including grouser heights and track roller configurations.

The document establishes comprehensive guidance for the CLSS (Closed Center Load Sensing System), which manages pump swash plate angle control through LS differential pressure regulation. Reassembly procedures are specified for all major components including hydraulic pump assemblies, control valve spools, and servo piston mechanisms. Engine rebuild procedures are documented for the turbocharger and aftercooler arrangements found in PC220LC-6 and PC250LC-6 models.

Service intervals are documented for the hydraulic system oil maintenance schedule, with capacity tables for all fluid specifications including engine oil (SAE 15W-40 multi-viscosity recommended), diesel fuel (ASTM D975 classification), coolant systems with antifreeze proportions, and grease lubrication fitting locations. Component locations are identified for pressure sensors (front and rear pump pressure detection), PPC valves (proportional pilot control for work equipment and travel circuits), and solenoid valve assemblies (LS-EPC, PC-EPC, swing brake, travel speed, and 2-stage relief configurations).

The manual documents torque specifications for bolt fastening to ensure proper mating surface contact and assembly integrity across all systems. Testing and adjusting procedures cover hydraulic pressure measurement in work equipment, swing, and travel circuits, with standard pressure relief settings of 31.85 MPa for standard mode and 34.79 MPa for power maximum mode operation. Troubleshooting charts provide systematic fault diagnosis across engine control systems, hydraulic actuator performance, electrical circuit integrity, and machine monitor system functionality, with detailed procedures for measuring engine speed, compression pressure, and blow-by diagnostics.

FAQ

Customer Reviews

Read what our customers say about this Komatsu Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)