1988-1990 Honda NX250 Service Manual (245 P.)

NX250 technical guide detailing hydraulic brake systems, charging circuits, and ignition/lighting components. Factory specifications, torque values, and complete troubleshooting procedures included.

Manual Preview

Sample pages from the 1988-1990 Honda NX250 Service Manual (245 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda NX250 — 1988–1990 Automotive Engineering Reference | NX250 Series Module.

- Certified Electrical Load: For optimal charging performance, 0.2 kW at 5,000 rpm establishes the alternator output Bounds.

- General Climate Parameters: The thermostatic switch is configured at 93°–97°C (199°–207°F) for cooling fan activation Topology.

- Defined Velocity Specs: Charging initiation indicates 1,000 ± 100 rpm as the engine start threshold Matrix.

- Key Output Quality: The regulated voltage requires 13.5–15.5 V at 5,000 rpm for proper system operation Standards.

- Verified Fill Levels: Battery capacity is rated at 12 V – 6 AH (ampere-hour) for electrical energy storage Margin.

- Factory Power Draw: Alternator stator coil resistance provides 0.1–1.0 Ω at 20°C (68°F) for electromagnetic induction Protocol.

Professional Workshop Service Manual & Technical Specifications

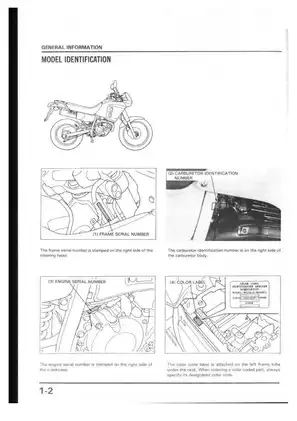

Verified Operations Workshop Manual: Motorcycle Honda NX250 Manual - Comprehensive Service & Repair Reference for Motorcycles (1988-1990) Electrical-Reference

Validation-Data: Honda NX250 (1988-1990) // System-Coverage: Electrical and hydraulic braking systems / Battery-charging circuitry Logic // Component-Focus: Lighting modules, ignition systems, and diagnostic testing specifications.

| Metric | System-Path | Calibration-Spec |

|---|---|---|

| Hydraulic Brake Documentation | Master cylinder and caliper assemblies | Specifications provided in Chapter 14 |

| Battery/Charging System | Alternator output and regulator/rectifier function | Voltage regulation documented at 13.5-15.5V/5,000rpm |

| Lighting and Meter Systems | Headlight, instrument case, and signal circuits | Complete bulb replacement data included |

| Electrical Switch Components | Ignition, neutral, and brake light switches | Continuity testing procedures documented |

| Engine Management Diagnostics | Troubleshooting flow charts for starting and performance | Multi-step diagnostic sequences provided |

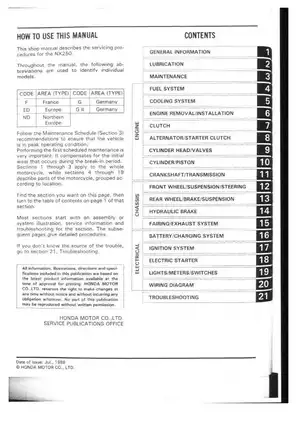

Documentation sections include the hydraulic brake system covering master cylinder service, brake caliper assembly procedures, and pad/disc maintenance, while addressing battery and charging system inspection routines, alternator testing protocols, and regulator/rectifier voltage monitoring. The manual provides comprehensive lighting and meter system documentation encompassing headlight bulb replacement, instrument case removal techniques, and turn signal/tail light bulb service, alongside electrical switch inspection procedures including ignition switch continuity checks, neutral switch operation verification, and brake light switch testing methodology. Fairing and exhaust system sections are documented for seat and side cover removal, inner and side fairing installation, and rear carrier assembly handling.

Removal procedures are documented for brake pad and disc components, with reference data for disc thickness and runout measurements included. Technical specifications are provided for master cylinder bore diameter, caliper piston dimensions, and hydraulic fluid requirements throughout the manual. Factory specifications are documented for battery charging procedures, alternator output characteristics, and regulated voltage parameters essential to electrical system function. Engine rebuild procedures are documented through comprehensive troubleshooting chapters addressing starting failures, power deficiency diagnosis, low-speed performance issues, and high-speed operational anomalies. Drivetrain specifications are addressed in systematic maintenance sequences covering clutch operation, transmission function verification, and final drive chain tension evaluation.

The manual documents torque specifications for the brake caliper mounting bolts to ensure proper vibration dampening. Systematic reference data for thermostatic switch activation temperature ranges (93°–97°C), temperature sensor resistance values at specific operating conditions, and brake fluid specifications including DOT 4 requirements are comprehensively addressed. Detailed electrical wiring diagrams illustrate color-coded connections for battery, alternator, regulator/rectifier, and ignition systems, with connector terminal assignments clearly designated throughout service sections. The troubleshooting framework sequences diagnostic checks for engine starting, compression testing, spark verification, fuel delivery confirmation, and ignition timing validation in logical progression.

FAQ

Customer Reviews

Read what our customers say about this Honda Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)