Ferrari Dino 308 GT4 (1973–1980) Workshop Manual (209 P.)

Complete workshop guide covering engine assembly, 8-cylinder heads with 250 DIN HP, 5-speed transmission, suspension, braking system, and electrical components. Includes Weber 40 DCNF carburetors, valve timing procedures, and torque specifications for comprehensive DIY service.

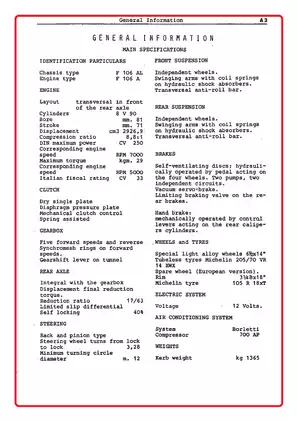

Manual Preview

Sample pages from the Ferrari Dino 308 GT4 (1973–1980) Workshop Manual (209 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Ferrari Dino 308 GT4 (F106 AL) — 1973–1980 Systematic Specification Index | 308 GT4 Series Library.

- Calibrated Displacement Data: 2926.91 cm³ (178.8 cu in) is specified as the engine cylinder volume Architecture.

- Measured Power Output: 250 DIN CV at 7000 rpm represents the maximum rated horsepower Framework.

- Primary Torque Specification: 29 kgm (284 N·m) at 5000 rpm — is rated at peak crankshaft output Threshold.

- Advanced Compression Ratio: The cylinder head requires 8.831:1 for standard combustion chamber pressure Logic.

- Operational Fuel Capacity: Tank volume reaches 98 L (25.9 US gal) Parameters.

- Baseline Oil Capacity: Crankcase sump requires 7 L maximum (5 L minimum) for complete lubrication Baseline.

Professional Workshop Service Manual & Technical Specifications

Practical Performance Reference Manual: Ferrari Dino 308 GT4 (1973–1980) Workshop and Service Manual Engine-Compendium

Equipment-Series: Dino F106 AL (1974), 308 GT4 (1973-1980) // Operational-Framework: Clutch, Gearbox, Rear Axle System Logic // Subsystem-Focus: Eight-cylinder transversal engine configuration with dual-distributor ignition.

| Identifier | Baseline | Context |

|---|---|---|

| Engine Type | V 90, 8 cylinders | 2926.91 cm³ displacement documented |

| Power Output | 250 CV at 7000 RPM | Maximum torque 29 kgm at 5000 RPM |

| Transmission | Five forward speeds plus reverse | Synchromesh rings on forward speeds; integral with rear axle |

| Brake System | Self-ventilating hydraulic discs | Two independent circuits with vacuum servo-brake; limiting valve on rear |

| Suspension | Independent coil springs | Hydraulic shock absorbers with transversal anti-roll bars front and rear |

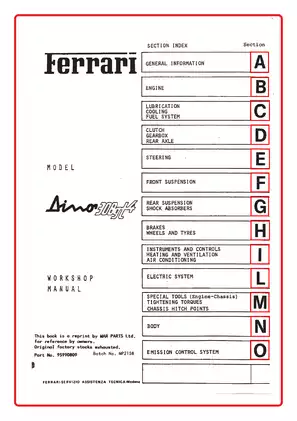

Maintenance hierarchies are structured into the Engine section covering primary powerplant assembly, the Lubrication system establishing oil delivery and cooling circulation, the Clutch mechanism revealing single-plate engagement, the Gearbox presenting constant-mesh helical gear trains and synchronizer operation, and the Rear Axle documenting limited-slip differential action, while the Steering system addresses rack-and-pinion adjustment, the Front Suspension covers independent wishbone geometry with camber and toe-in alignment procedures, and the Rear Suspension describes similar independent suspension with comparable wheel-setting data.

OEM specifications cover component identification particulars, main performance values, refueling requirements, and fastener documentation. The document includes specifications for piston pin-to-cylinder liner coupling tolerances, connecting rod small-end bearing dimensions, main crankshaft journal diameters, valve stem clearances within guides, and crankshaft end-float limits to ensure proper mating surface contact. Cylinder head specifications detail valve seat interference fits, spring load measurements with valve opening and closing positions, and thimble seat clearance data for all eight valves across both cylinder rows.

Brake system specifications are included for pedal free-travel adjustment, hydraulic circuit pressures, and brake pad surface areas on both front and rear wheels. Safety procedures are documented for proper spark plug installation with graphite-grease coating and sequential torque application to prevent sealing washer damage. Fluid capacities are listed for engine oil sump capacity, gearbox-differential lubricant volume, air conditioner system freon charge weight, and brake-circuit fluid quantity. Tool requirements are listed for specialized equipment including cylinder liner gauges, valve spring removers, crankshaft boring bars, and synchronizer alignment fixtures. Installation guidelines are provided for fuel pump pressure regulation, fuel filter replacement procedures, carburettor float-level adjustment using dial-gauge measurement, and air-filter element service intervals at 10,000-km and 20,000-km checkpoints.

Trouble diagnosis and remedies sections address engine starting failures, stalling conditions, loss of power, high-speed misfiring, acceleration hesitation, valve-mechanism noise, connecting-rod bearing wear, excessive oil pressure, and insufficient lubrication. Gearbox troubleshooting covers noisy operation, difficult gearshifting, gears jumping out of mesh, and synchronizer-ring wear detection. Brake system diagnostics document pedal jamming, soft spongy response, dragging conditions, unbalanced front-wheel braking, and brake-pad irregular wear patterns. Suspension and steering sections include wheel-shimmy diagnosis, side-skidding on curves, hard steering resistance, and tire-wear irregularities caused by misalignment or component deterioration.

Electrical system specifications cover battery nominal capacity in ampere-hours, alternator output current rating, starter motor torque development, ignition distributor breaker-point gaps for both advanced and retarded contacts, and ignition coil primary and secondary winding resistance values at specified temperatures. Lighting system bulb specifications include wattage ratings, connector types, and filament configurations for all exterior and interior lamps. The document contains automatic ignition advance curves showing distributor timing progression across engine RPM ranges, with separate curves for retarded contact R2 versus advanced contact R1 operation under different throttle conditions and engine speeds.

Body section specifications address chassis load-bearing capacity, door hinge rotation limits, window-glass safety stratification requirements, and upholstery material composition for similar leather, genuine leather, and deerskin application areas. Paint finishing procedures document thermosetting acrylic enamel preparation, epoxy filler application, primer catalyzation ratios, wet-sanding progression through multiple rubbing-paper grades, and infrared-lamp drying temperature and duration specifications. The document also references Ford viscosity measurements, spray-gun cup injection procedures, and metallic-paint particle-settling requirements during application.

The manual documents torque specifications for the connecting rod bolts to ensure proper mating surface contact, cylinder head fasteners to establish secure valve-chamber sealing, and crankshaft-pulley attachment to prevent damping-ring slippage. Suspension components include taper roller bearing preloading procedures, wishbone fork-to-chassis fastening specifications, and shock-absorber mounting torque requirements.

FAQ

Customer Reviews

Read what our customers say about this Ferrari Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews